- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Buy Gr2 Titanium Plate – Premium ASTM B265 Grade Material

For high-performance applications requiring erosion resistance and auxiliary strength, Gr2 Titanium Plate is the industry standard. This commercially unadulterated titanium review is perfect for chemical preparation, sea building, and imperative mechanical assignments due to its strength and formability. These ASTM B265-compliant plates give the ideal mix of mechanical quality and erosion security for advanced businesses.

Understanding Gr2 Titanium Plate – Specifications and Properties

Understanding the specifications and qualities of your materials is essential to every successful industrial project. Gr2 Titanium Plate is commercially pure and performs well in demanding applications.

Chemical Composition and Purity Standards

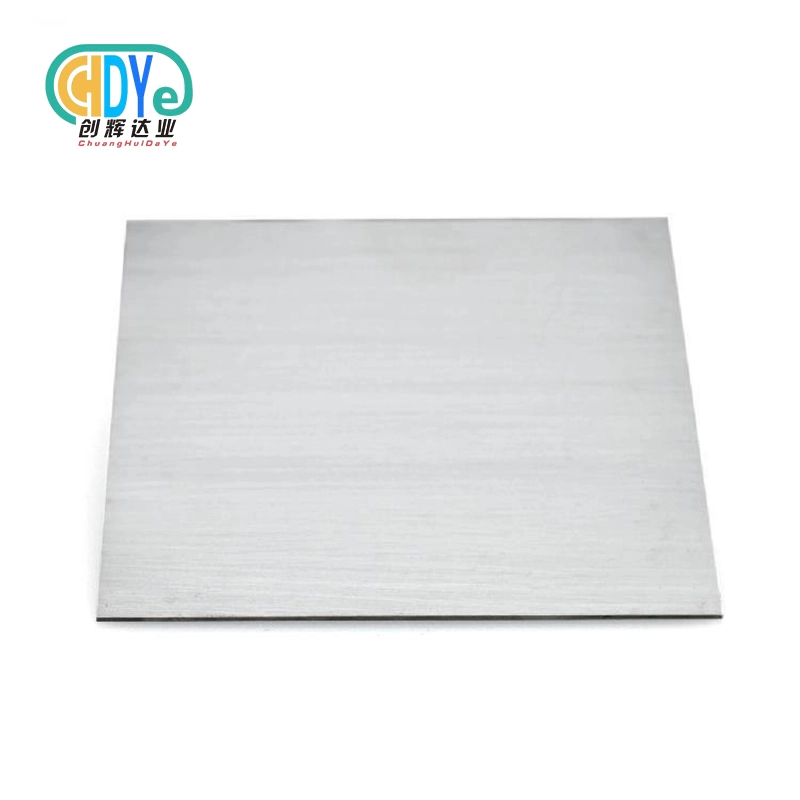

With 99.2% titanium and carefully managed trace elements, Grade 2 titanium is extremely pure. This mixture has 0.25% iron, 0.03% carbon, 0.08% oxygen, and 0.015% nitrogen. These precise elemental ratios give the material outstanding corrosion resistance and mechanical stability, making it perfect for chemically compatible applications.

Manufacturing standards ensure that each plate fulfills ASTM B265 and ISO 5832 standards, giving procurement specialists confidence that materials will perform consistently across operational conditions. Controlling interstitial elements, especially oxygen and nitrogen, affects ductility and formability.

Mechanical Properties and Performance Metrics

This titanium grade's mechanical qualities illustrate its building significance. With a thickness of 4.51g/cm³, these plates are half the weight of steel and have 1.5 times the quality of normal steel. This exceptional strength-to-weight proportion makes it an appropriate lightweight aviation and marine development material.

Typical surrender quality is 275 to 410 MPa, whereas ductile quality is 345 to 483 MPa. The fabric has extraordinary formability for perplexing development due to its 20% prolongation in 50mm gage length.

Temperature and Corrosion Resistance Characteristics

Without property debasement, working temperatures extend from cryogenic to 300°C. In spite of this wide temperature range, the fabric holds its erosion resistance and basic integrity.

Unlike normal materials, this review stands up to erosion in discussion, seawater, and most acidic and soluble environments. The fabric is steady indeed with unforgiving corrosives like water regia, making it perfect for chemical preparation and sea applications.

Comparing Gr2 Titanium Plate with Other Titanium Grades and Metals

Understanding how grades and alternative metals compare in performance, cost, and application compatibility helps choose the best material. This comparison helps procurement experts choose based on project needs.

Performance Comparison Across Titanium Grades

Grade 2 titanium has a balanced set of qualities that sets it apart from other grades. It is stronger than Grade 1 and has better ductility and corrosion resistance. Grade 1 titanium has improved formability but lesser strength, which may not exceed structural requirements for demanding applications.

Grade 5 titanium (Ti-6Al-4V) is stronger but more expensive and requires more heat treatment. Grade 5's alpha-beta alloy structure is ideal for aircraft applications that require the greatest strength, while Grade 2's commercially pure composition resists chemical and marine corrosion.

Material Advantages Over Stainless Steel

Comparing titanium plates to stainless steel appears to have solid preferences that legitimize its use in basic applications. Titanium plates are 40% lighter than stainless steel components, a major gain.

Corrosion resistance surpasses most stainless steel grades, particularly in chloride-rich conditions where stainless steel may pit or experience erosion break. Titanium is top-notch for therapeutic gadget fabrication since it is biocompatible and meets human tissue contact benchmarks.

Cost Analysis and Long-term Value Considerations

Titanium plates cost more than stainless steel, but lifetime cost analysis favors them for long-term uses. Reduced maintenance, increased service life, and no protective coatings save money over the equipment's lifetime.

Market pricing trends show stable supply from established manufacturers and competitive pricing through direct factory contacts. Long-term partnerships with certified suppliers can assure competitive pricing, consistent quality, and delivery.

Practical Guide to Procuring Gr2 Titanium Plates

Supplier competencies, order needs, and quality assurance processes are crucial to procurement. This thorough methodology ensures material purchases meet project timeframes and performance requirements.

Key Buying Considerations and Order Requirements

Supplier minimum order quantities vary, but conventional dimensions start at 100 kg. Depending on processing complexity, custom sizing and thickness may require bigger minimum orders. Most providers offer 1000mm x 2000mm to 1500mm x 3000mm plates with thicknesses from 1mm to 80mm.

Standard product lead times are 4–8 weeks, whereas special specifications might take 10–16 weeks, depending on processing complexity. Planning procurement ahead of project needs assures material availability without affecting project deadlines.

Supplier Evaluation and Certification Requirements

Supplier selection begins with titanium-experienced manufacturers to ensure quality. The minimum quality management standard is ISO 9001:2015, although aerospace applications may require AS9100 certification.

Material test certificates, chemical analysis reports, and mechanical property verification should document traceability. Suppliers should track documents from the raw material source to the final product delivery to ensure regulatory and quality compliance.

Balancing Quality, Price, and Reliability

Long-term supplier ties ensure pricing and quality stability. Assessing suppliers' technical skills, production capability, and customer service responsiveness helps select partners who can meet expanding business needs.

Price negotiations should reflect the overall cost of ownership, not just the purchase price. Delivery reliability, technical support availability, and quality consistency are crucial to project success and should be considered in supplier selection.

Manufacturing, Usage, and Maintenance of Gr2 Titanium Plate

Understanding production and handling practices improves material performance and service life. Engineers and procurement teams can specify processing and maintenance requirements with this knowledge.

Manufacturing Processes and Quality Control

The production process begins with vacuum melting for purity and homogeneity. Raw titanium sponge is electron beam melted or vacuum arc remelted to make high-quality ingots with uniform chemical composition and little contamination.

Hot rolling at temperatures over the recrystallization point (800°C–1000°C) is followed by controlled cooling to obtain mechanical characteristics. Annealing improves ductility and stress alleviation, whereas cold rolling improves surface polish.

Quality control includes ultrasonic testing for internal defects, dimensional inspection for thickness consistency, and mechanical testing for strength and ductility. Surface quality examination assures smooth finishes without faults that could cause tension or corrosion.

Welding and Machining Best Practices

Inert gas shielding, usually argon, prevents ambient contamination during welding. Good weld integrity requires careful cleaning and degreasing of the joint. Preheating is not necessary, but thick-section applications may benefit from post-weld stress release.

Sharp cutting tools and appropriate coolant flow reduce heat and work hardening in machining. With titanium-specific cutting speeds and feed rates, conventional machining works well.

Cleaning and Maintenance Protocols

Regular cleaning maintains surface condition and prevents corrosion-compromising contaminants. Surface impurities can be removed without damaging the oxide layer with mild alkaline or titanium cleansers.

Inspections should check high-stress or corrosive areas for surface damage or atypical wear. A clean, dry atmosphere avoids contamination and preserves material during long-term storage.

Choosing Gr2 Titanium Plate for Your Industry Needs

Specific sectors benefit from the Gr2 Titanium Plate's unique characteristics. Understanding these uses helps uncover situations where this material outperforms others.

Aerospace and Defense Applications

The aircraft industry values the high strength-to-weight ratio that reduces weight without compromising structural integrity. Titanium's excellent operating temperature resistance and dimensional stability benefit aircraft structural components, engine parts, and fasteners.

Aircraft subjected to de-icing chemicals or marine conditions need corrosion resistance. Critical components that could fail catastrophically benefit from the material's stress corrosion cracking and fatigue resistance.

Chemical Processing and Marine Industries

The chemical processing equipment uses titanium's resistance to strong chemicals and high temperatures. Stainless steel heat exchangers, reaction vessels, and piping systems break quickly, whereas these plates last longer.

Seawater corrosion resistance eliminates the need for protective coatings or cathodic protection devices in marine applications. Titanium's durability reduces maintenance and extends service intervals in offshore platform components, ship hulls, and propeller systems.

Medical Device Manufacturing

Grade 2 titanium is biocompatible and necessary for medical implants and surgical instruments. Non-toxic, odorless, and non-irritating, the material is safe for long-term interaction with tissues and body fluids.

Titanium's elastic modulus matches human bone, lowering stress shielding in orthopedic implants like hip and knee replacements. Dental implants join directly to bone using osseointegration for long-term results.

Company Introduction and Our Product & Service Offering

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is based in Baoji High-tech Development Zone, China's titanium hub. Our "Titanium Capital" location gives us access to superior industrial facilities and specific technical expertise gained over decades of titanium production.

Our technical basis for quality excellence comes from our founder's 30-year rare metal industry experience. We can understand complex applications and produce materials that meet or exceed customer expectations due to our experience.

The company manufactures titanium using vacuum melting, hot forging, and precise rolling. Our processing capacity provides 2000mm-wide plates for industrial-scale fabrication projects with reliable delivery schedules.

ISO 9001:2015-certified quality management systems govern raw material inspection, melting and forging, machining, and final inspection methods to ensure product quality. Every shipment has complete traceability paperwork to verify material authenticity and specifications.

We offer custom processing for unique purposes in addition to typical plate designs. Our technical staff collaborates with customers to find the best solutions for project needs, such as dimensions, surface treatments, and mechanical properties.

Our excellent customer service shows our dedication to long-term worldwide client engagements. Successful project outcomes and corporate growth depend on technical support, competitive pricing, and reliable delivery.

Conclusion

For industries that need corrosion resistance, strength, and reliability, ASTM B265 Gr2 Titanium Plates perform well. Its biocompatibility and high strength-to-weight ratio make it ideal for aerospace, chemical processing, marine, and medical applications. Companies may get high-quality materials that last and perform well by selecting suppliers and procuring them properly. Established suppliers' production knowledge and quality assurance methods assure constant product performance that satisfies modern industrial application standards.

FAQ

Q: What makes Grade 2 titanium different from other titanium grades?

A: Grade 2 titanium represents commercially pure titanium with 99.2% titanium content, offering excellent corrosion resistance and moderate strength. Compared to Grade 1, it provides enhanced strength while maintaining superior ductility. Unlike Grade 5 (Ti-6Al-4V), which offers higher strength through alloying, Grade 2 delivers better corrosion resistance and easier fabrication at a more economical price point.

Q: How does ASTM B265 certification ensure material quality?

A: ASTM B265 standards specify precise requirements for chemical composition, mechanical properties, and manufacturing processes. This certification guarantees that materials meet stringent quality criteria, including tensile strength, yield strength, and elongation values. Certified materials undergo comprehensive testing and inspection protocols to verify compliance with these standards.

Q:What are the typical lead times for custom titanium plate orders?

A: Standard titanium plates typically require 5-10days for delivery, while custom specifications may need 2- 3 weeks, depending on complexity. Factors affecting lead times include thickness requirements, surface finish specifications, and dimensional tolerances. Planning procurement activities well in advance ensures that material availability aligns with project schedules.

Partner with Chuanghui Daye for Premium Titanium Solutions

Ready to source premium Gr2 Titanium Plate for your critical applications? Chuanghui Daye combines three decades of rare metal expertise with state-of-the-art manufacturing capabilities to deliver ASTM B265-certified materials that meet your exact specifications. Our ISO 9001:2015 quality management system ensures consistent product excellence, while our location in China's Titanium Capital provides competitive pricing and reliable supply chain management. Contact our technical team at info@chdymetal.com to discuss your project requirements and discover how our Gr2 titanium plate manufacturer capabilities can support your success with customized solutions and dependable delivery schedules.

References

1. American Society for Testing and Materials. ASTM B265-20: Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate. ASTM International, 2020.

2. Boyer, R.R. "An Overview on the Use of Titanium in the Aerospace Industry." Materials Science and Engineering: A, vol. 213, no. 1-2, 1996, pp. 103-114.

3. Donachie, Matthew J. Titanium: A Technical Guide, Second Edition. ASM International, 2000.

4. International Organization for Standardization. ISO 5832-2:2018: Implants for Surgery - Metallic Materials - Part 2: Unalloyed Titanium. ISO, 2018.

5. Lütjering, Gerd, and James C. Williams. Titanium: Engineering Materials and Processes. Springer-Verlag, 2007.

6. Schutz, R.W., and H.B. Watkins. "Recent Developments in Titanium Alloy Application in the Energy Industry." Materials Science and Engineering: A, vol. 243, no. 1-2, 1998, pp. 305-315.

Learn about our latest products and discounts through SMS or email