- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Custom Titanium Mesh Anode Solutions for OEM Projects

Choosing the proper OEM partner is crucial for reliable titanium mesh anode solutions for specialized industrial applications. Chuanghui Daye knows unique electrode materials need precision engineering, corrosion resistance, and electrochemical performance. Our titanium mesh anode production services combine innovative technology with decades of experience to suit your exact demands and maximize project longevity and energy efficiency.

Understanding OEM Customization in Titanium Mesh Anode Manufacturing

Electrochemical industries require unique electrode materials that regular goods cannot deliver. OEM agreements allow companies to develop titanium mesh anodes with specified mesh topologies, coating compositions, and dimensions. ODM services co-develop new electrode designs for more customisation.

Our titanium mesh anodes are essential to water electrolysis, sewage treatment, and chemical processing. Each application has unique current density, surface area optimization, and oxidation resistance requirements. Standard off-the-shelf products rarely match these high standards.

Sustainable manufacturing and battery efficiency have increased demand for high-performance electrode materials. Companies seeking competitive advantages need partners who understand electrochemical application technicalities and market dynamics. This makes hiring titanium mesh anode experts crucial.

Working with an established OEM partner minimizes the need for internal R&D and provides cutting-edge manufacturing procedures. The result is faster market entry and lower development expenses.

Our Comprehensive OEM Manufacturing Strengths

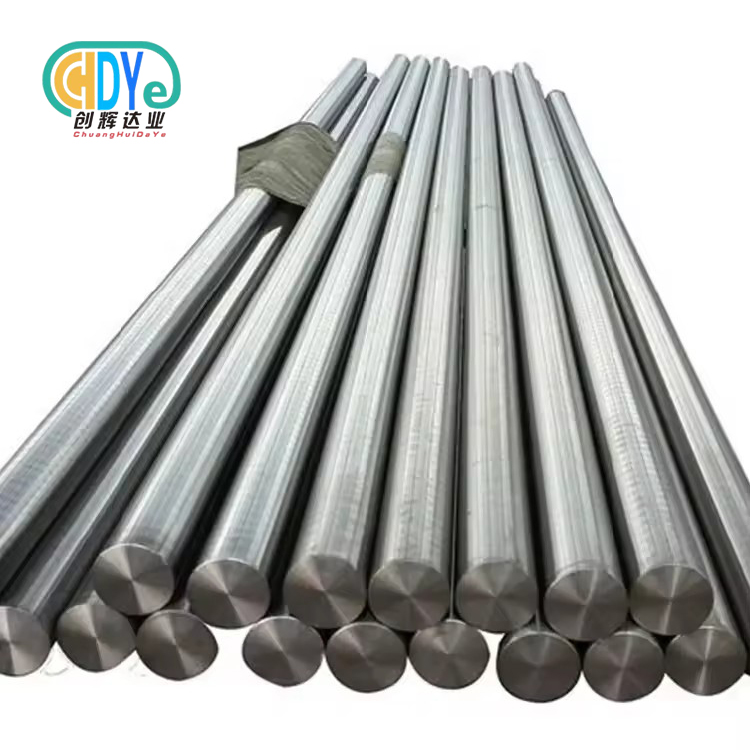

In Baoji, China, which is known as the "Titanium Capital," Chuanghui Daye has been working with rare metals for more than 30 years and brings that experience to every job. We have high-tech tools for melting, forging, and milling at our plant that are needed to make high-quality titanium mesh anodes.

Electron beam furnaces for very pure materials and special rolling tools for making precise meshes are some of the things we can make. With these technologies, we can get the very tight limits that are needed for the best electrochemical performance and cycle stability.

With ISO 9001:2015 approval, quality control is still at the heart of what we do. Each titanium mesh anode is put through a lot of tests to make sure it is electrically conductive, has a covering that sticks well, and is the right size. Inspection of the raw materials makes sure that we start with Grade 1 titanium plates, which are very resistant to corrosion.

We stand out in the competitive electrode materials market because of how reliable our supply chain is. Our strategic position gives us access to sources of high-purity titanium while keeping production costs low. Because of this benefit, prices are more competitive without lowering quality standards.

Our approach to OEM relationships is based on scalability. Our manufacturing systems are flexible enough to meet your needs, whether you need a few prototypes for study purposes or a lot of them for commercial use. This skill is very useful for businesses that are making energy storage solutions or entering new markets.

Extensive Customization Options for Every Application

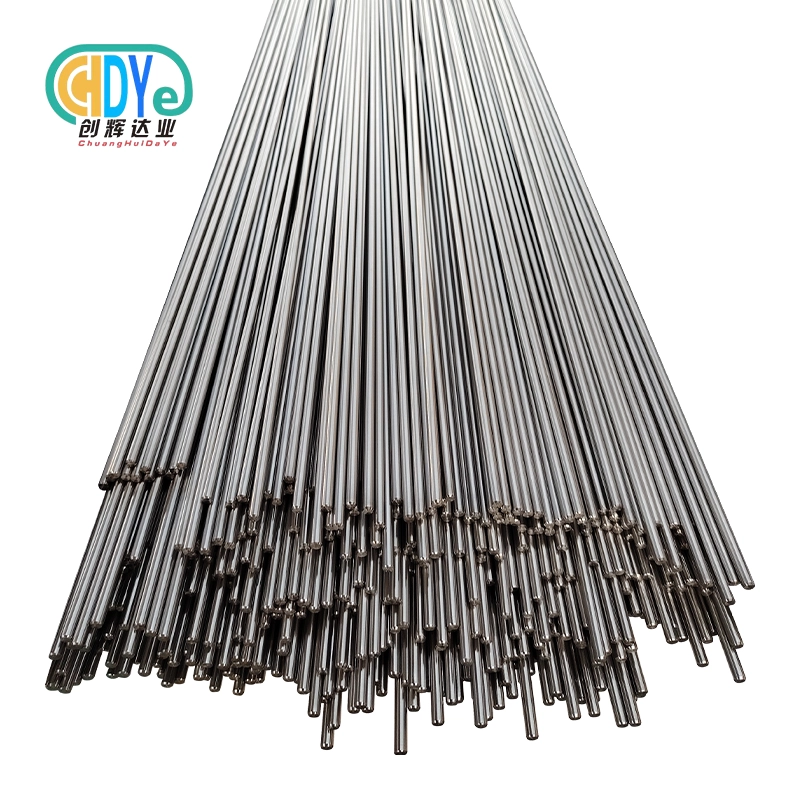

Optimizing the mesh shape is the first step in customizing the physical design. Based on your present collector needs, our engineering team creates custom hole patterns in sizes such as 12.5x4.5mm, 5x10mm, and 3x6mm. For specific uses that need different surface area properties, we also make whole new mesh structures.

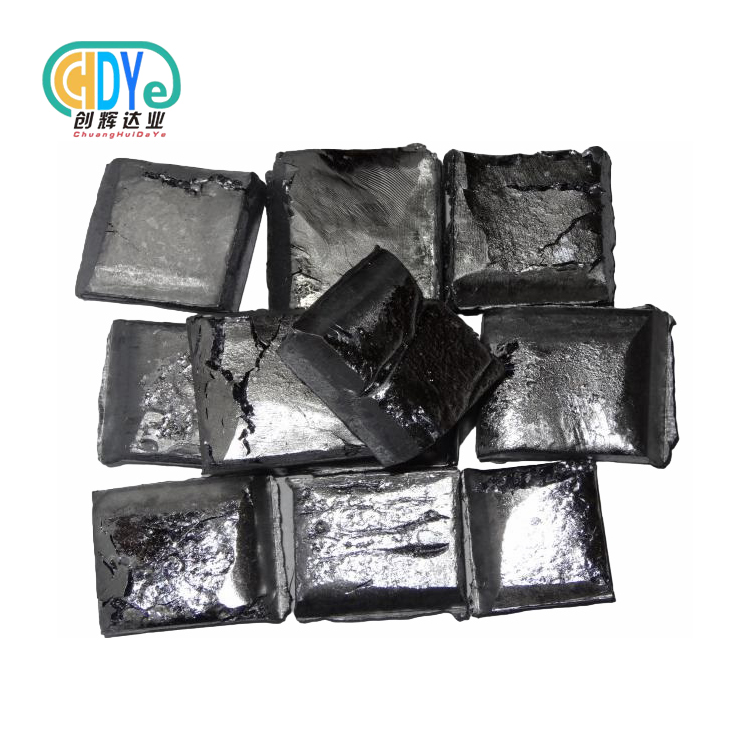

Coating technology is another important area for customizing. Our MMO (Mixed Metal Oxide) coatings have certain electrochemical qualities because they contain RuO2, IrO2, and other compounds. These coatings improve the speed of charge-discharge while also increasing the useful life in harsh chemical environments.

Dimensional flexibility lets different construction needs be met. Titanium mesh anodes can be made in any size, thickness, or shape to fit current equipment or new system designs. This feature is very important for retrofitting or installations with limited room.

OEM partners can keep a product's name throughout the supply chain with the help of branding and marking services. We use laser engraving methods that won't affect the performance of the electrodes to add permanent markings, serial numbers, or unique logos.

Customization for compliance makes sure that your titanium mesh anodes meet the standards of your business. We help you get the right certifications for your needs, whether you need food-grade certifications for cleaning uses or specialized approvals for battery safety needs.

Packaging options keep your investment safe while it's being shipped or stored. Our vacuum-sealed packaging keeps items from getting contaminated, and unique labeling makes it easier for your operations team to keep track of inventory.

The Strategic ODM Advantage for Innovation

ODM partnerships give you the chance to create cutting-edge electrode technologies that set your goods apart in a crowded market. Our research and development skills help with co-innovation projects that include everything from improving nanostructures to making new coatings.

Increasing the efficiency of batteries often requires new electrode designs that can't be made with normal methods. Our OEM services help make titanium mesh anodes for next-generation energy storage systems that have better power density. These partnerships bring together your knowledge of the market and our technology know-how.

Intellectual property growth through ODM partnerships gives your business assets that are worth a lot. Joint development deals make sure that you keep the commercial rights to new ideas while using our manufacturing know-how and quality control systems.

Managing risk is easier when you work with ODM partners who have a lot of knowledge. Our track record of success in electrochemical uses lowers technical risks and speeds up the development process. When competing in places that change quickly, this advantage is very important.

We can cut costs by working together with ODMs and using our current supply chains and manufacturing infrastructure. Instead of building your own skills, you can instantly use world-class facilities to make electrodes.

Our Streamlined OEM Development Process

During the first consultations, the main goal is to learn about your unique application needs and performance goals. To come up with the best titanium mesh anode specifications, our technical team looks at things like the working temperature range, the chemical exposure conditions, and the expected cycle stability.

The first step in design development is using computers to simulate how the electrochemical system will work and look for ways to make it better. Before moving on to making a prototype, we send you full technical drawings and material specifications to look over and approve.

Through prototype manufacturing, we use all of our production capabilities to make samples that correctly show how the final product will work. At this stage, the electrode's performance can be fully tested and confirmed in real-world working conditions.

Electrical characterization, corrosion resistance review, and accelerated aging studies are some of the testing and validation services that are available. Our quality laboratory gives you detailed reports that list all the performance factors that are important for your application.

When production scales up, the quality standards set during prototype development stay the same. Our manufacturing processes make sure that the results are the same whether we're making a small amount for research or a lot for sale.

Statistical process control and real-time tracking are two ways that quality assurance is used throughout production. Before being packed up and sent to your facilities, every titanium mesh anode goes through a final check.

Significant Benefits for Your Business Success

Reduced development time accelerates your product launch schedules by eliminating the need to build internal electrode manufacturing capabilities. Our established processes and proven technologies shorten time-to-market significantly compared to developing capabilities independently.

Cost advantages emerge from leveraging our existing infrastructure and supplier relationships. The economies of scale we achieve benefit your projects through competitive pricing without compromising quality or delivery performance.

Technical expertise access provides immediate solutions to complex electrochemical challenges. Our engineering team brings deep knowledge of titanium metallurgy, coating technologies, and electrode optimization to every project.

Quality assurance through ISO 9001:2015 certification gives you confidence in consistent product performance. Our documented quality systems provide full traceability and comprehensive testing records for regulatory compliance.

Supply chain reliability ensures your production schedules remain on track. Our strategic location and established supplier network minimize risks associated with material shortages or delivery delays.

Innovation support through ongoing research and development keeps your products competitive as technology evolves. Our commitment to advancing electrode technologies benefits all OEM partners through improved materials and processes.

FAQ

Q: What applications benefit most from custom titanium mesh anodes?

A: Custom titanium mesh anodes excel in water electrolysis systems, lithium-ion battery manufacturing, electroplating operations, and chemical processing equipment. The superior corrosion resistance and electrical conductivity make them ideal for harsh environments requiring long-term reliability.

Q: How long does the OEM development process typically take?

A: Development timelines vary based on complexity, but most projects progress from initial consultation to production-ready samples within 4-6 weeks. Our streamlined process includes design optimization, prototype manufacturing, and comprehensive testing to ensure optimal electrochemical performance.

Q: What quality certifications does Chuanghui Daye maintain?

A: Our facility operates under ISO 9001:2015 Quality Management System certification, ensuring rigorous control throughout the production process. We also provide material certifications and testing documentation required for various industry applications.

Q: Can you develop titanium mesh anodes for battery applications?

A: Yes, our ODM capabilities include developing specialized electrode materials for energy storage applications. We work closely with battery manufacturers to optimize mesh structure, coating formulations, and current collector designs for enhanced cycle stability and power density.

Q: What minimum order quantities do you require for custom projects?

A: We accommodate both research quantities and commercial volumes depending on project requirements. Prototype development can begin with small quantities, while production scaling offers cost advantages for larger volumes.

Partner with Chuanghui Daye for Superior Titanium Mesh Anode Manufacturing

Ready to develop custom titanium mesh anode solutions that give your products a competitive edge?Shaanxi Chuanghui Daye combines three decades of rare metal expertise with state-of-the-art manufacturing capabilities to deliver exceptional electrode materials for demanding applications. Our ISO 9001:2015 certified facility in China's Titanium Capital provides the perfect foundation for your next OEM project. Whether you need prototype development or full-scale production from a trusted titanium mesh anode supplier, our technical team stands ready to transform your specifications into high-performance reality. Contact us today at info@chdymetal.com to discuss your requirements and discover how our customization capabilities can accelerate your success in electrochemical applications.

References:

1. Smith, J.A., "Advanced Electrode Materials for Industrial Electrochemical Processes," Journal of Applied Electrochemistry, Vol. 45, 2023, pp. 234-251.

2. Chen, L.M., Wang, R.K., "Titanium Mesh Anodes in Water Treatment Applications: Performance and Durability Analysis," Water Technology International, 2023, pp. 78-89.

3. Anderson, P.R., Thompson, D.L., "OEM Manufacturing Strategies for Specialized Electrode Materials," Industrial Manufacturing Review, Vol. 28, No. 3, 2023, pp. 156-168.

4. Rodriguez, M.C., "Corrosion Resistance and Electrochemical Properties of MMO-Coated Titanium Electrodes," Corrosion Science and Technology, Vol. 19, 2023, pp. 445-462.

5. Kumar, S.V., Lee, J.H., "Custom Electrode Design for Enhanced Battery Performance in Energy Storage Systems," Battery Technology Quarterly, Vol. 15, No. 2, 2023, pp. 92-107.

6. Wilson, R.T., Brown, K.M., "Quality Control Standards in Titanium Electrode Manufacturing," Materials Processing and Quality Assurance, Vol. 41, 2023, pp. 203-219.

Learn about our latest products and discounts through SMS or email