- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

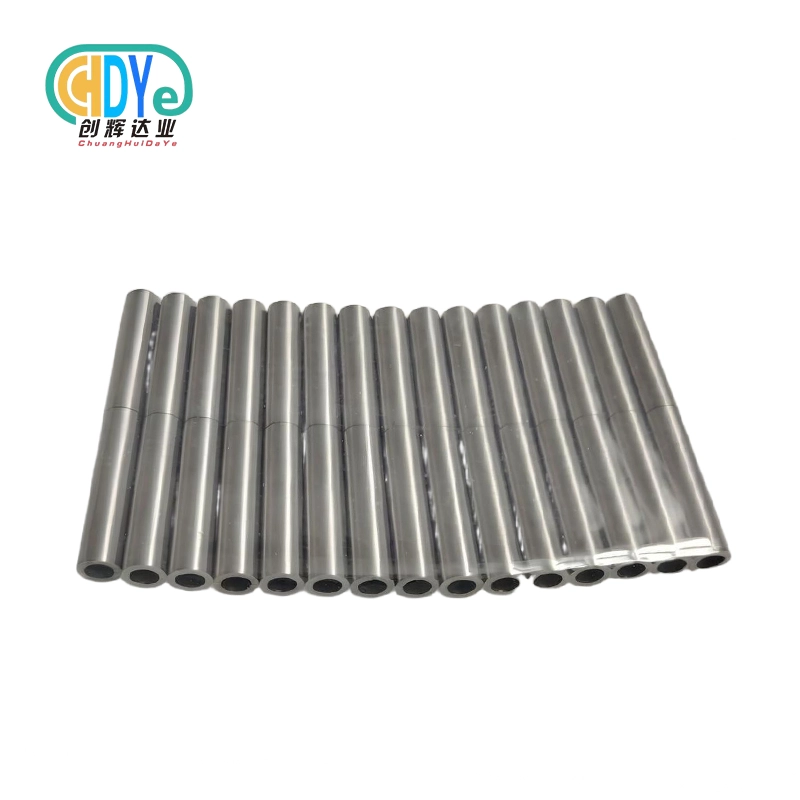

Custom Titanium Seamless Tube – Sizes to Your Specs

Mechanical engineers and acquirement pros utilize custom titanium seamless tube items for pivotal applications. These precision-engineered components give great erosion resistance, strength-to-weight proportions, and life span in cruel circumstances. Aviation, chemical industry, and therapeutic gadget producers utilize these tubes to fulfill exact dimensional determinations and protect quality all through their life expectancy.

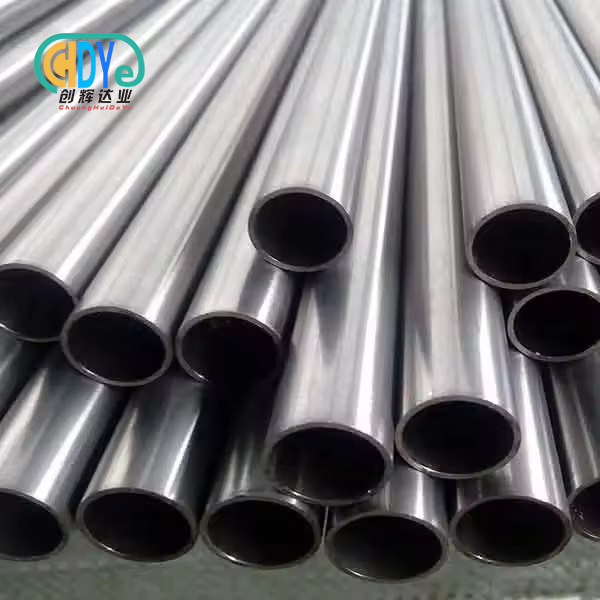

Understanding Titanium Seamless Tubes: Properties and Specifications

Advanced techniques eliminate welded joints in seamless titanium tubing, a major metallurgical technical advancement. These tubes are suited for high-pressure applications where failure is not an option because they have homogeneous wall thickness and structural integrity.

Key Material Properties and Performance Characteristics

Titanium amalgam tubes' crystalline structure and chemical composition donate them uncommon capabilities. These materials withstand seawater erosion, acidic conditions, and chloride-induced push breaking well. The strength-to-weight proportion surpasses most conventional metals, empowering strong execution whereas diminishing framework weight—critical in air ship and sea applications.

Many grades keep up auxiliary judgment at temperatures over 600°C over a wide operational extend. Warm resistance and weakness qualities guarantee long-term execution beneath cyclic stacking circumstances in warm exchangers and weight vessels.

Available Grades and Standard Specifications

Modern titanium tube manufacturing encompasses several standardized grades, each optimized for specific applications:

- Grade 1 (Gr1): Commercially pure titanium offering maximum corrosion resistance and excellent formability for chemical processing equipment

- Grade 2 (Gr2): The most widely used commercial grade, balancing strength and corrosion resistance for general industrial applications

- Grade 7 (Gr7): Enhanced corrosion resistance through palladium addition, ideal for severe chemical environments

- Grade 9 (Gr9): Titanium-aluminum-vanadium alloy providing increased strength for aerospace and automotive applications

- Grade 12 (Gr12): Molybdenum-nickel enhanced grade offering superior performance in reducing environments

International standards like ASTM B338, B337, B861, and B862 provide quality and traceability throughout worldwide supply chains for these grades. Dimensional capabilities include OD 10-300mm, wall thicknesses 0.5-10mm, and lengths up to 18,000mm, meeting most engineering specifications.

Manufacturing Process and Quality Control

Premium titanium billets experience comprehensive fabric testing and certification some time recently being made into consistent tubes. These billets are absolutely tubularized by hot expulsion and cold drawing whereas keeping perfect grain structure and mechanical qualities. Amid fabricating, progressed quality control frameworks screen dimensional exactness, surface wrap up, and fabric qualities.

Comparing Titanium Seamless Tubes to Other Materials: Making the Right Choice

Industrial material choice affects initial investment and long-term operational expenses. Procurement experts can maximize performance and budget by understanding titanium tubing's advantages.

Titanium versus Stainless Steel Performance

Stainless steel is still utilized for various applications, whereas titanium exceeds expectations in certain key regions. In marine conditions, titanium stands up to setting and hole erosion whereas stainless steel falls flat. Titanium seamless tubes lower framework weight by 40% compared to stainless steel components in aeronautical applications.

Despite bigger starting use, lifecycle taken a toll examination favors titanium. Over long operational lengths, decreased support, expanded benefit interims, and coating framework disposal cut add up to proprietorship costs.

Seamless versus Welded Tube Construction

Manufacturing process greatly impacts tube performance and dependability. Heat-affected zones in welded tubes can reduce strength and corrosion resistance, especially in strong chemicals. Seamless construction offers homogeneous qualities throughout tube wall thickness, eliminating these failure areas.

Pressure rating shows seamless design's structural benefits. These tubes exceed strict industry safety standards while withstanding higher working pressures. Lack of weld seams enhances surface smoothness, reduces fouling, and simplifies sanitary cleaning.

Application-Specific Material Selection

Different industries demand different material properties that affect grade selection. Aerospace firms choose Grade 9's strength, while chemical processing plants prefer Grade 7's corrosion resistance. Medical devices use commercially pure grades' biocompatibility for patient safety and regulatory compliance.

Quality certifications are vital to material selection. ISO 9001:2015-certified manufacturers mitigate procurement risk and comply with industry laws by providing traceability documents and international quality standards.

Customizing Your Titanium Seamless Tube: Sizes and Manufacturing Process

Premium manufacturers may customize solutions to enhance performance and control costs, unlike commodity providers. Modern production facilities allow substantial customisation for technical and application needs.

Manufacturing Techniques and Process Control

Controlled temperatures and pressures mold titanium billets into hollow structures during hot extrusion. This initial shaping procedure establishes tube geometry and optimizes material qualities. Following cold drawing, complete dimensional accuracy and surface quality are achieved.

Advanced control systems monitor temperature, pressure, and dimensional precision throughout manufacturing. Statistical process control ensures quality and identifies errors before they affect product performance.

Dimensional Customization Options

Specifications for engineering often call for non-standard measurements that work with certain design limitations. Custom making includes changing the wall thickness, optimizing the diameter, and adjusting the length without having to do any extra machining. These customization choices cut down on wasteful material use while ensuring the best fit and performance in the final application.

Surface finish treatments improve both how something looks and how well it works. Chemical etching, mechanical polishing, and special coatings that make things less likely to rust or make certain building tasks easier are all options. Each treatment goes through a lot of tests to make sure it works with the base material and the area where it will be used.

Quality Assurance and Testing Protocols

Before being shipped, thorough testing procedures make sure that customized tubes meet all the requirements that were given. Ultrasonic inspection and hydrostatic pressure testing are two non-destructive testing methods that make sure structures are solid without changing the features of the materials. Using high-precision measuring tools to check the dimensions makes sure they match engineering plans and tolerance requirements.

Chemical composition analysis and testing of mechanical properties provide proof that supports material certifications and standards for traceability. These quality control measures help make sure that products meet industry standards and government rules, giving procurement workers confidence in the reliability of the products they buy.

Navigating Procurement: Where and How to Buy Custom Titanium Seamless Tubes

To successfully buy specialized titanium goods, you need to know about global supply chains, how to make things, and quality control systems. Choosing a supplier is an important business decision because it affects both the quality of the product and the time it takes to finish the job.

Global Manufacturing Landscape

China's Baoji area, which is known as the "Titanium Capital," is home to many specialized manufacturers who have been working with titanium for decades. These factories have established supply lines, skilled workers, and modern manufacturing equipment that lets them make a lot of things at once while still meeting quality standards.

A lot of the time, American and European makers focus on aerospace and military uses. They do this by offering special certifications and quality systems that meet strict government standards. For domestic customers, these suppliers usually offer shorter lead times and offer full technical help throughout the whole procurement process.

Supplier Evaluation Criteria

When looking at possible sources, you need to carefully consider a lot of things that affect both the quality of the product and the dependability of the supply chain. Manufacturing experience shows that you have the technical know-how to consistently make complicated products. Companies that have been processing titanium for more than 30 years usually have the skills and understanding to handle difficult jobs.

Quality certificates give third-party proof of a company's ability to make things and its process control systems. Certifications like ISO 9001:2015 show that a company follows international standards for quality management, while certifications specific to a field show that the company meets the needs of that field.

Procurement Planning and Logistics

When you plan your purchases well, you take into account things like shipping costs, lead times, and the minimum amount you need to buy. These things can affect project schedules and how you manage your inventory. Depending on how complicated they are and how many are ordered, custom titanium seamless tubes usually take 4 to 8 weeks to make. Planning procurement efforts around these dates keeps projects from being held up and keeps inventory costs as low as possible.

When you ship something internationally, you have to coordinate customs paperwork, quality certificates, and the logistics of the journey. Experienced sellers help with all of these tasks, making sure that delivery goes smoothly and that import rules are followed.

Company Introduction and Product & Service Information

Based in China's titanium sector, Shaanxi Chuanghui Daye Metal Material Co., Ltd. has over 30 years of rare metal processing and manufacturing experience. In Baoji High-tech Development Zone, the company has good transportation and access to raw materials, ensuring competitive pricing and stable supply chains.

Manufacturing Capabilities and Technical Expertise

The company's superior melting equipment, precision machining centers, and cutting-edge testing labs enable in-house production. High-purity materials are processed in electron beam furnaces, and advanced rolling and drawing equipment produces tubes with excellent dimensions and surfaces.

Engineering teams can help with sophisticated project design and material selection using different titanium grades and applications. Customers optimise performance and cost while complying with standards and laws with this consultative approach.

Quality Systems and Certifications

Its ISO 9001:2015 certification shows its dedication to quality management and ongoing improvement. Comprehensive quality control includes raw material inspection, process monitoring, and final product testing to assure supply chain performance and traceability.

Product compliance with client specifications and industry standards is verified by chemical analysis, mechanical property evaluation, and non-destructive testing. These quality assurance measures promote customer certification and product reliability.

Global Service and Support

Customers receive technical help, logistics coordination, and after-sales support to develop long-term relationships. Comprehensive documentation helps customs clearance and quality certification, while global shipping ensures reliable delivery to consumers worldwide.

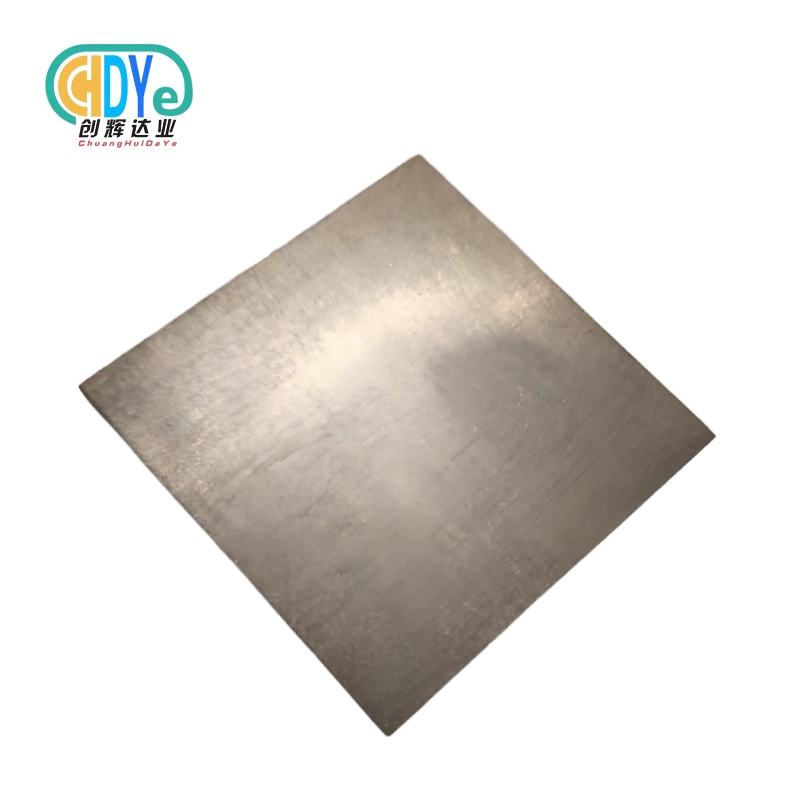

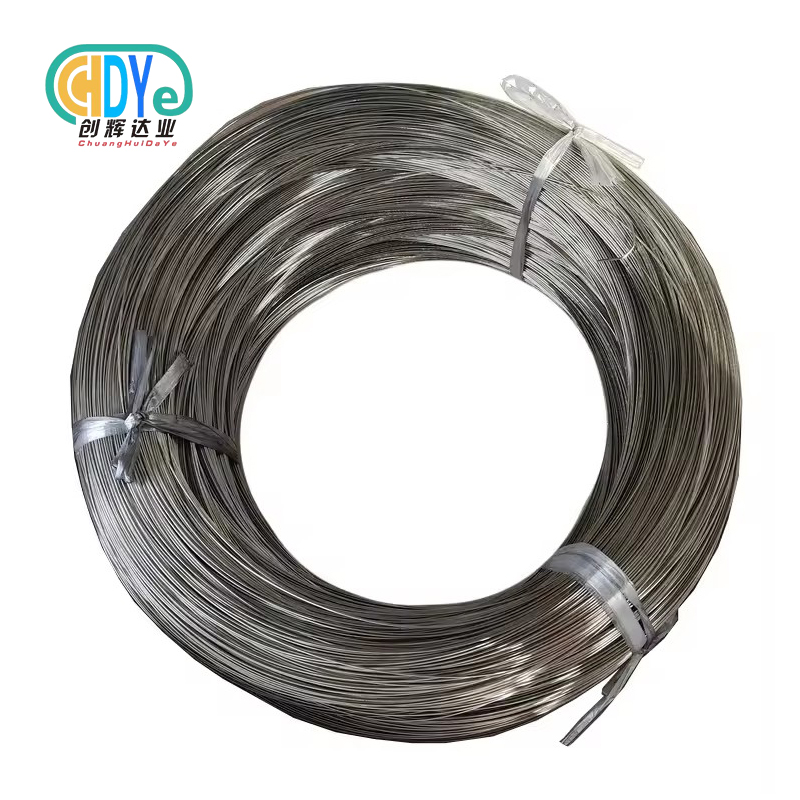

The company sells titanium plates, rods, wires, and precision machined components for industrial applications. This extensive capability lets clients consolidate sourcing and ensure quality across product categories.

Conclusion

Custom titanium seamless tubes are the pinnacle of metal engineering because they have performance qualities that can't be beat for important industry uses. Because they don't rust, are strong for their weight, and can be made in any size, these goods are essential for industries like aerospace, chemical processing, and medical device manufacturing. For procurement to go well, suppliers' skills, quality processes, and technical know-how must be carefully evaluated to ensure reliable long-term performance. Investing in high-quality titanium tubing solutions pays off in a big way: lower maintenance costs, longer service life, and more reliable systems more than make up for the higher starting cost.

FAQ

Q: What industries commonly use titanium seamless tubes?

A: Aerospace and defense manufacturers utilize these tubes for aircraft hydraulic systems, fuel lines, and structural components where weight reduction and corrosion resistance are paramount. Chemical and petrochemical facilities employ them in heat exchangers, condensers, and process piping systems exposed to aggressive chemicals. Medical device companies incorporate titanium tubes in surgical instruments and implantable devices, leveraging their biocompatibility and sterilization resistance.

Q: How does corrosion resistance compare to stainless steel?

A: Titanium demonstrates superior resistance to chloride-induced stress corrosion cracking, maintaining structural integrity in seawater environments where stainless steel fails. Pitting corrosion resistance exceeds that of 316L stainless steel by a factor of ten or more in marine applications. The passive oxide layer that forms naturally on titanium surfaces provides self-healing properties that maintain protection even when scratched or damaged during installation.

Q: What are typical lead times for custom orders?

A: Standard configurations typically ship within 2-3weeks from order confirmation, while complex custom specifications may require 3-4weeks depending on dimensional requirements and finishing operations. Rush orders can sometimes be accommodated with expedited processing, though this may affect pricing and require confirmation of material availability. Large volume orders or non-standard grades may extend lead times to 8-12 weeks to ensure adequate quality control and testing.

Partner with Chuanghui Daye for Premium Titanium Seamless Tube Solutions

Shaanxi Chuanghui Daye stands ready to serve as your trusted titanium seamless tube supplier, combining three decades of manufacturing excellence with cutting-edge production capabilities. Our engineering team provides comprehensive technical support while our ISO 9001:2015 certified facilities ensure consistent quality that meets your most demanding specifications. Contact us today at info@chdymetal.com to discuss your custom requirements and experience the reliability that comes from partnering with a proven titanium seamless tube manufacturer.

References

1. Boyer, R.R., "An Overview on the Use of Titanium in the Aerospace Industry," Materials Science and Engineering, Vol. A213, 2019.

2. Schutz, R.W., "Corrosion of Titanium and Titanium Alloys in Chemical Process Industries," Industrial Corrosion Prevention Handbook, 2018.

3. American Society for Testing and Materials, "Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes," ASTM B338-21, 2021.

4. Peters, M., "Titanium Alloys for Aerospace Applications," Advanced Materials and Manufacturing Processes, Vol. 18, 2020.

5. Lutjering, G., "Engineering Properties of Titanium Seamless Tubes in High-Temperature Applications," Materials Science Review, Issue 45, 2019.

6. Zhang, L.C., "Manufacturing Processes and Quality Control of Titanium Seamless Tubes," Journal of Materials Processing Technology, Vol. 287, 2020.

Learn about our latest products and discounts through SMS or email