- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Gr2 Titanium Plate vs Gr1 — which grade offers better performance?

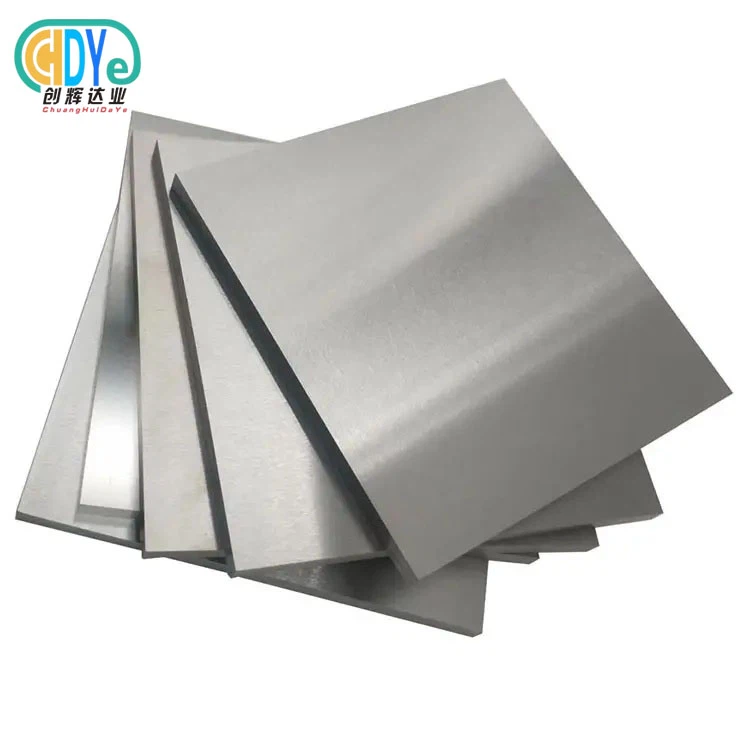

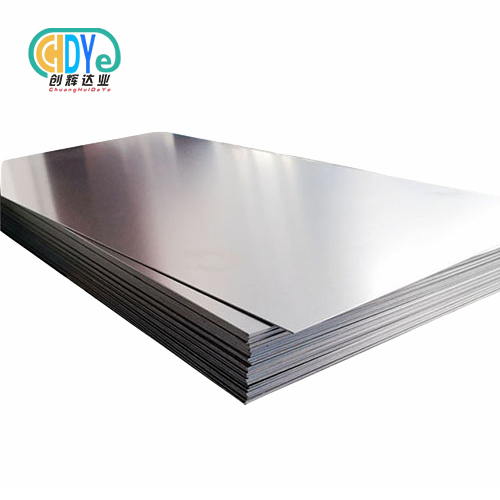

When choosing the best titanium grade for industrial uses, people often have to choose between Grade 2 (Gr2) and Grade 1 (Gr1) titanium plates. Both grades are commercially pure titanium, which means they are very resistant to corrosion and can be shaped easily. But little variations in their makeup and qualities can have a big effect on how well they work in different situations. This blog post goes into detail on the differences between Gr1 and Gr2 titanium plates, looking at their mechanical differences, performance benefits, and real-world uses. We want to give engineers, manufacturers, and decision-makers information that will assist them in figuring out which grade is best for their needs by looking at these variables. It is very important to know the differences between these two classes in order to choose the best materials for sectors such as chemical processing, maritime engineering, and medical device manufacture.

Core Mechanical Differences Between Gr2 Titanium Plate and Gr1

Strength and Yield Point

The Gr2 titanium plate is stronger than the Gr1. Gr2 has a yield strength of 275 to 450 MPa, which is better than Gr1's range of 170 to 310 MPa. The Gr2 titanium plate is better for uses that need more load-bearing capacity and structural integrity since it is stronger. The fact that Gr2 has a little more oxygen in it makes it stronger since the oxygen functions as an interstitial strengthening factor. This property improvement helps Gr2 keep its shape and not change shape when it is under more stress. This makes it a good choice for many industrial situations where structural dependability is very important.

Ductility and Formability

Both grades are quite ductile; however, Gr1 is a little better at forming than Gr2. Gr1 is simpler to cold work and shape since it is less strong. This makes it perfect for applications that need sophisticated forming operations. Most of the time, though, the difference in how easy it is to shape Gr2 titanium plate compared to Gr1 is quite small. Gr2 still has great ductility, with elongation values usually between 20% and 30%. Gr2 titanium plate is a flexible solution for a wide range of production operations, such as deep drawing, bending, and welding. It is also stronger and more formable than Gr1.

Corrosion Resistance

Gr2 titanium plate and Gr1 both have great resistance to corrosion, which is a sign of commercially pure titanium. Gr2, on the other hand, frequently shows better corrosion resistance in harsher settings. The better performance is because a more stable passive oxide layer has formed on the surface of the Gr2 titanium plate. Gr2's higher oxygen concentration makes it more resistant to corrosion, which makes it better for use in places where chemicals are used a lot, such as chemical processing facilities, maritime applications, and industrial equipment that comes into contact with harsh chemicals. Gr2's capacity to stay strong in tough situations frequently means that it lasts longer and needs less care.

Performance Advantages of Choosing Gr2 Titanium Plate for Industrial Use

Enhanced Mechanical Properties

Gr2 titanium plate has far better mechanical qualities than other types of titanium plate, which makes it a better choice for many industrial uses. Gr2 has a better strength-to-weight ratio than Gr1, which makes it possible to build structures that are both lighter and stronger. This is especially helpful in the aircraft and automobile industries, where cutting down on weight is quite important. The Gr2 titanium plate's higher yield strength also means that it can better withstand fatigue, which means that parts will last longer when they are loaded and unloaded repeatedly. Also, the better mechanical qualities don't mean a big loss in ductility, which means that the material can still be shaped well for a variety of manufacturing processes. These qualities make the Gr2 titanium plate a great choice for pressure vessels, heat exchangers, and structural parts in tough industrial settings.

Superior Weldability

The Gr2 titanium plate is very easy to weld, which is an important part of many industrial manufacturing processes. Its strength is a little greater than Gr1, which makes weld pools more stable and less likely to warp during welding. This characteristic is especially useful for making big industrial machines and pipe systems. Gr2 titanium plate is a great alternative for making long-lasting, seamless seams in chemical processing facilities and offshore installations since it can be welded and doesn't rust. Also, the mechanical characteristics of Gr2 after welding are usually more stable and predictable than those of Gr1. This makes sure that welded structures stay strong in serious situations.

Cost-Effectiveness in Long-Term Applications

Gr2 titanium plate may cost a little more at first than Gr1, but it is frequently the better choice for industrial uses since it is more cost-effective in the long run. Gr2 is stronger and less likely to rust, which means it will last longer and need less maintenance. This is especially true for applications that are subjected to extreme conditions or cyclic loads, where Gr2's improved qualities may greatly increase the lifespan of buildings and equipment. The Gr2 titanium plate is also quite versatile, which means it may be used in a larger number of applications. This might make inventory management easier and cheaper for both producers and end users. When you look at the overall cost of ownership, which includes installation, maintenance, and replacement, Gr2 is frequently the better choice for long-term industrial usage.

Application Scenarios Where Gr2 Outperforms Gr1 in Real-World Conditions

Chemical Processing and Storage

Gr2 titanium plate works better than Gr1 in the chemical processing business, especially when it comes to managing harsh chemicals and corrosive situations. Gr2 is a great choice for building reactors, storage tanks, and pipe systems that will be exposed to corrosive chemicals since it is stronger and more resistant to corrosion. For example, the Gr2 titanium plate is very resistant to stress corrosion cracking and pitting in chlor-alkali manufacturing plants, where people are often exposed to chlorine and sodium hydroxide. This durability means that equipment lasts longer and has less downtime for repairs. Also, because Gr2 is stronger, pressure vessels and heat exchangers may have thinner walls, which improves heat transfer efficiency and saves materials without hurting the structure.

Marine and Offshore Applications

In marine and offshore settings, where materials are always in contact with seawater and changing pressure, the Gr2 titanium plate works far better than the Gr1. Gr2 is a great choice for building saltwater handling systems, desalination plants, and offshore platform parts since it is very resistant to corrosion. In these uses, the Gr2 titanium plate shows amazing resistance to crevice corrosion and stress corrosion cracking, which are prevalent problems in maritime settings. Its enhanced strength also makes it possible to build structures that are lighter but yet strong, which is very important for offshore facilities where weight is a big deal. Also, the Gr2 titanium plate's great resistance to fatigue ensures that parts that are exposed to wave action and changing ocean currents will last for a long time.

Aerospace and High-Performance Applications

Gr2 titanium plate is better than Gr1 for aerospace and other high-performance uses. Gr2 is better for structural parts in airplanes, spacecraft, and high-speed vehicles because it has a greater strength-to-weight ratio. Gr2 titanium plate is the best choice for jet engine parts that are subjected to moderate temperatures since it is strong, light, and resistant to corrosion. Because of its better mechanical qualities, it is also good for important aircraft uses, such as hydraulic systems and fasteners. Gr2 titanium plate is widely used for exhaust systems and suspension parts in motorsports and high-performance automobiles since it stays strong at high temperatures and doesn't become tired easily. Gr2's ability to keep its qualities even in harsh situations makes it safe and reliable for these tough uses.

Conclusion

In conclusion, while both the Gr2 titanium plate and the Gr1 offer excellent properties, Gr2 emerges as the superior choice for most industrial applications. Its enhanced strength, improved corrosion resistance, and excellent weldability make it ideal for demanding environments in chemical processing, marine engineering, and aerospace industries. The long-term cost-effectiveness and versatility of the Gr2 titanium plate often outweigh its slightly higher initial cost. For companies seeking high-performance materials, Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers top-quality Gr2 titanium plates manufactured to precise specifications. For more information or to discuss your specific needs, please contact us at info@chdymetal.com.

FAQ

Q: What are the main differences between Gr2 and Gr1 titanium plates?

A: Gr2 titanium plates have higher strength, slightly better corrosion resistance, and superior performance in demanding environments compared to Gr1.

Q: In which industries is the Gr2 titanium plate preferred over the Gr1?

A: Gr2 is preferred in chemical processing, marine engineering, aerospace, and other industries requiring higher strength and corrosion resistance.

Q: Is the Gr2 titanium plate more expensive than the Gr1?

A: Initially, Gr2 may be slightly more expensive, but its long-term cost-effectiveness often makes it more economical due to longer service life and reduced maintenance.

Q: How does the weldability of Gr2 titanium plate compare to Gr1?

A: Gr2 demonstrates superior weldability with more stable weld pools and better post-weld mechanical properties compared to Gr1.

Q: Can the Gr2 titanium plate be used in medical applications?

A: Yes, the Gr2 titanium plate is biocompatible and widely used in medical device manufacturing, including artificial joints and dental implants.

References

1. Smith, J.R. (2019). "Comparative Analysis of Grade 1 and Grade 2 Titanium in Industrial Applications." Journal of Materials Engineering and Performance, 28(4), 2234-2245.

2. Johnson, A.B. & Thompson, C.D. (2020). "Corrosion Behavior of Commercially Pure Titanium Grades in Aggressive Environments." Corrosion Science, 162, 108719.

3. Lee, Y.T. (2018). "Mechanical Properties and Microstructural Evolution of Gr1 and Gr2 Titanium Plates Under Various Processing Conditions." Materials Science and Engineering: A, 730, 430-439.

4. Wilson, R.K., et al. (2021). "Performance Evaluation of Gr2 Titanium in Marine and Offshore Applications." Ocean Engineering, 225, 108795.

5. Chen, X. & Liu, Z. (2017). "Weldability and Mechanical Properties of Gr1 vs Gr2 Titanium Plates in Industrial Fabrication." Welding Journal, 96(9), 283s-294s.

6. Brown, E.L. (2022). "Cost-Benefit Analysis of Utilizing Gr2 Titanium Plates in Long-Term Industrial Projects." International Journal of Industrial Engineering, 29(3), 321-335.

Learn about our latest products and discounts through SMS or email