When selecting the appropriate pure titanium sheet, it is necessary to give careful consideration to the grade criteria, the application requirements, and the capabilities of the provider. There is a wide range of strength levels and corrosion resistance qualities available in commercially pure titanium sheets, ranging from grade 1 to grade 4. In order for your project to be successful, it is essential that the qualities of the material conform to the specific requirements of the industry. This is true whether you are making medical devices, chemical processing equipment, or aircraft components.

Understanding Pure Titanium Sheet Grades and Their Applications

The various grades of pure titanium that are available for commercial use each have varying degrees of oxygen concentration and mechanical characteristics. Titanium sheet of grade 1 offers the highest possible formability and resistance to corrosion, making it an excellent choice for chemical processing applications that need complex forming procedures. For general industrial applications, Grade 2 is considered to be the workhorse grade because it provides a superb blend of strength, ductility, and weldability.

Titanium sheet of grade 3 is characterized by enhanced strength while retaining its excellent formability features. Applications that require higher mechanical qualities than what Grade 2 can supply are suitable for this grade. The fourth grade has the maximum strength among the commercially pure grades, but it has poorer formability compared to the grades that come before it.

For structural components, aerospace manufacturers commonly request Grade 2 due to the fact that it has a demonstrated track record and consistently delivers reliable performance. Grade 1 is frequently selected by manufacturers of chemical equipment for the construction of intricate heat exchanger designs that require lengthy shaping procedures. Grade 2 is the standard for implantable components that are chosen by producers of medical devices. This grade is chosen when biocompatibility and strength standards are met.

Critical Material Properties to Evaluate

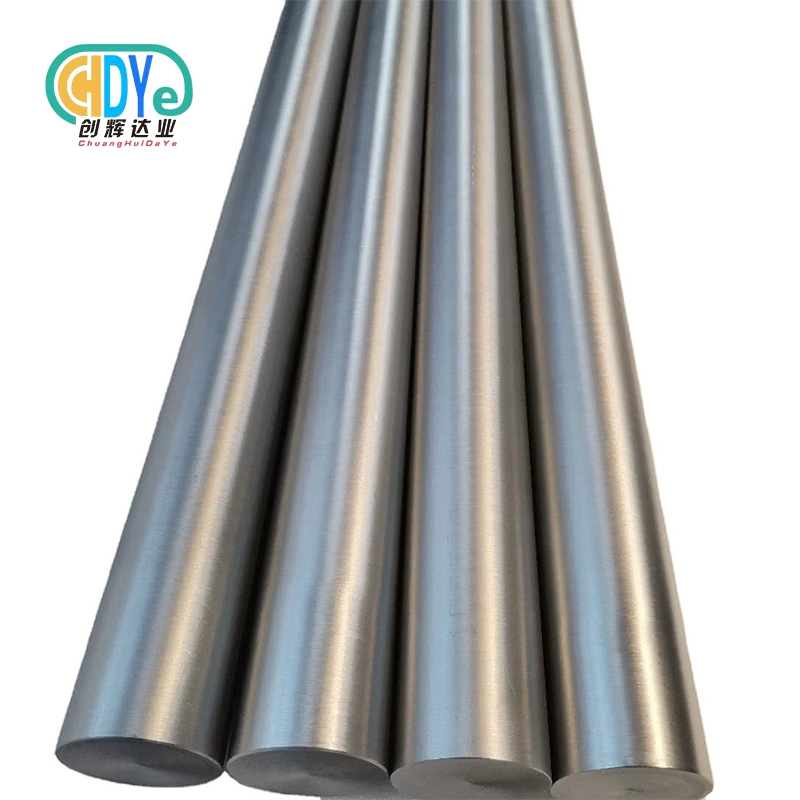

The tensile strength of titanium varies greatly from grade to grade, with Grade 1 having a tensile strength of 240 MPa and Grade 4 having a tensile strength of 550 MPa. The yield strength follows similar patterns, which makes it important to select the appropriate material based on the load-bearing needs. As the strength grows, the elongation qualities gradually diminish, which has an effect on the formability and fabrication processes.

Resistance to corrosion continues to be high across the board for all commercially pure grades. Titanium is capable of forming a protective oxide layer that may regenerate when it is damaged, so providing protection that is long-lasting in difficult situations. Because of this property, a pure titanium plate is ideal for use in applications involving seawater, applications involving chemical processing, and marine conditions where other materials are not suited.

The performance of the temperature range extends from cryogenic levels to about 350 degrees Celsius for operations that are sustained. When the temperature is higher, it is necessary to take into account the effects of oxidation and the potential changes in properties. The thermal conductivity of this metal is still rather poor in comparison to that of other metals, which has an impact on applications involving heat transfer and welding techniques.

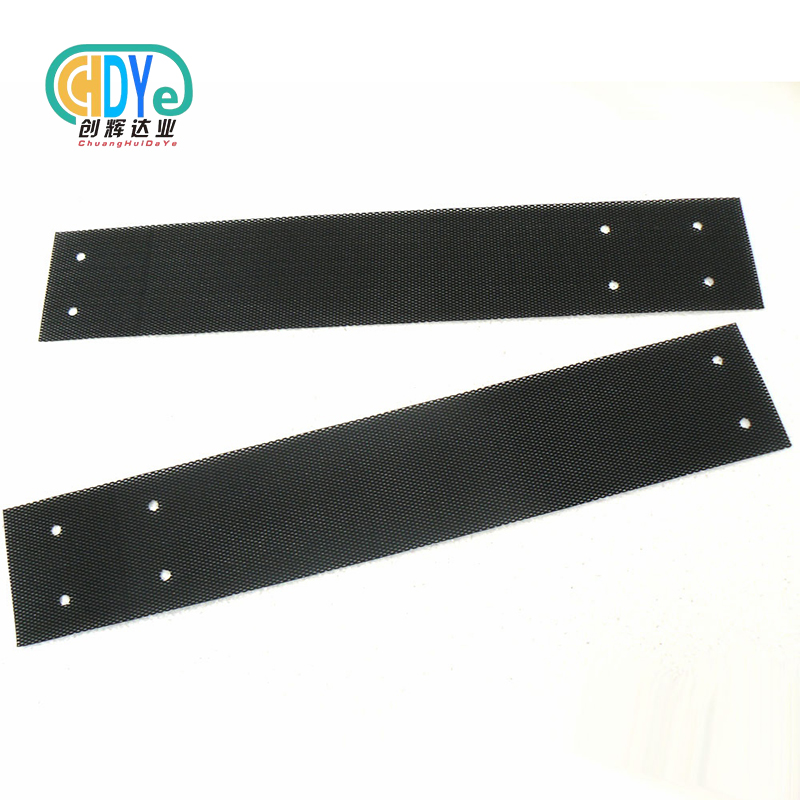

The quality of the surface finish has an effect on both the appearance and the performance of many different applications. Surfaces with a mill finish offer satisfactory performance for the majority of industrial applications, whereas polished surfaces are suitable for applications in the medical and food processing industries that require greater cleanability.

Dimensional Considerations and Stock Availability

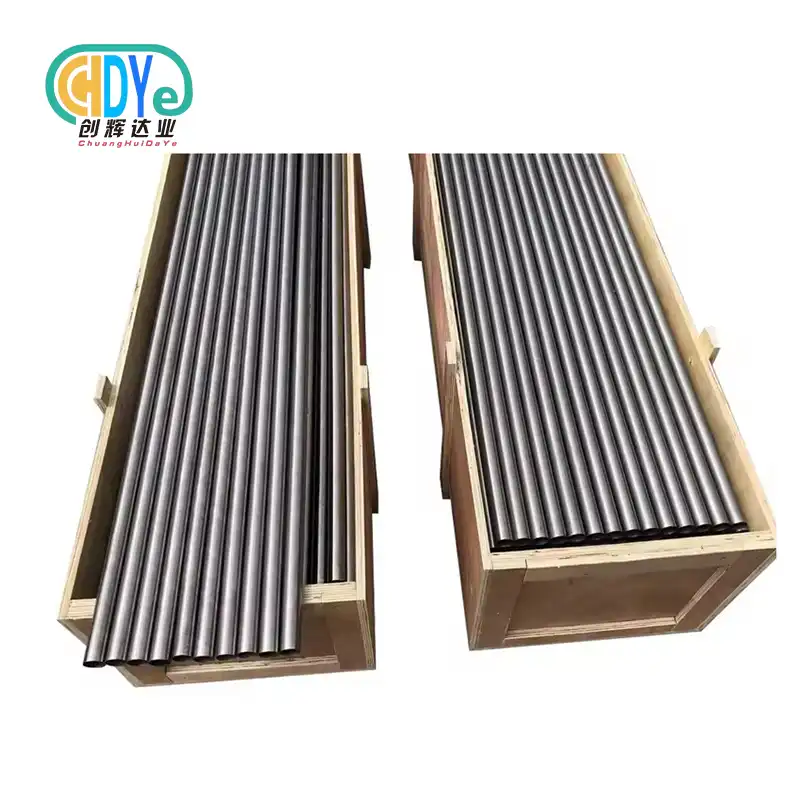

The thickness of pure titanium sheets normally falls somewhere between 0.5 millimeters and 50 millimeters; however, these thicknesses can be customized through the use of specialized rolling techniques. The widths that are considered standard are 1000mm, 1200mm, and 1500mm, while the lengths that are typically available from stock are up to 3000mm. When it comes to non-standard dimensions, lead times and minimum order quantities are required to be extended.

The requirements for thickness tolerance vary depending on the application, with aeronautical and medical applications requiring more stringent restrictions than common industrial uses. When it comes to structural applications, standard tolerances of ±0.1mm are typically sufficient. However, precision applications may require tolerances of ±0.05mm or even more stringent.

Whenever an application involves precision machining or forming procedures, flatness standards become an extremely important consideration. The measures of bow and camber have an impact on the usage of materials and the prices of downstream processing. During the production and storage processes, quality suppliers adhere to stringent flatness compliance requirements.

Both the safety and the efficiency of the processing are impacted by the edge condition. While sheared edges offer cost-effective options for a wide variety of applications, machined edges give exceptional edge quality for work that requires exacting precision. During the handling and processing processes, safety dangers are eliminated when edges are deburred.

Manufacturing and Processing Considerations

The machining of pure titanium sheets necessitates the utilization of specialized tools and methods due to the one-of-a-kind characteristics of the material. Work hardening and tool wear can be avoided by using cutting tools that are sharp, operating at the optimum speeds and feeds, and with sufficient cooling. There is a general consensus that carbide tooling offers superior performance versus high-speed steel for the majority of operation types.

The processes for welding require considerable attention to be paid to the regulation of heat input and the coverage of shielding gas. The weld pool and the heat-affected zone are both shielded from contamination by the argon shielding. When it comes to full-penetration welding, backing gas becomes very necessary in order to avoid root contamination and brittle development.

The outstanding springback qualities and work hardening behavior of titanium are beneficial to the operations of forming. Forming at room temperature is suitable for a wide variety of applications, but warm forming expands opportunities for the creation of complicated shapes. During the forming process, galling and surface damage can be avoided by designing the tools in the appropriate manner.

Both stress relief and annealing techniques are included in the range of heat treatment options. While removing residual tensions, stress relief at temperatures between 480 and 650 degrees Celsius does not appreciably influence mechanical qualities. Optimum ductility and relief from work hardening caused by forming processes can be achieved with full annealing at temperatures ranging from 700 to 800 degrees Celsius.

Quality Assurance and Certification Requirements

For applications that are of fundamental importance, the documentation of material certification provides essential traceability. For the purpose of verifying chemical composition, mechanical qualities, and dimensional conformance, mill test certificates are utilized. Testing by a third party might be necessary for applications in the fields of aircraft, medicine, or nuclear technology.

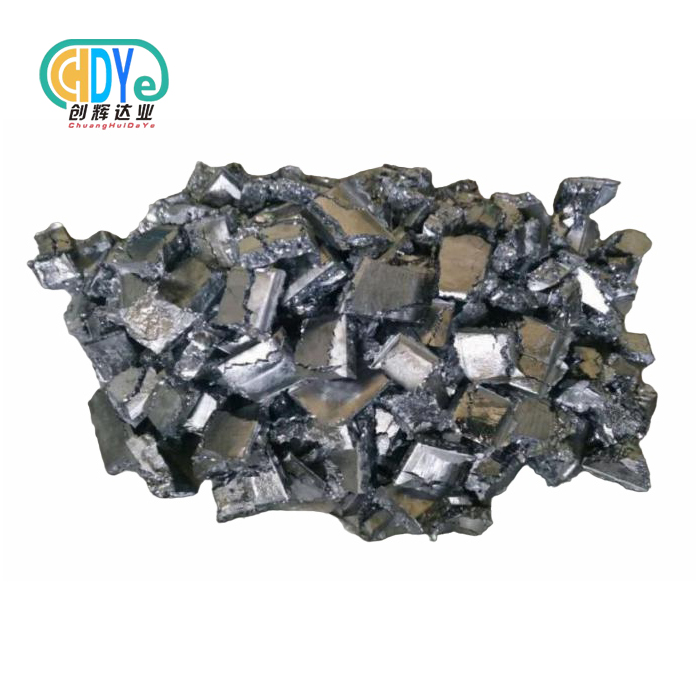

Compliance with grade standards and control of contamination are both ensured by chemical composition verification. Both the mechanical qualities and the resistance to corrosion are directly influenced by the amount of oxygen, nitrogen, carbon, and iron present. Within the context of specialized applications, trace elements can have a considerable impact on performance.

The qualities of strength, ductility, and hardness are validated by the use of mechanical testing. Values for elongation, yield strength, and ultimate strength can be obtained through tensile testing of the material. A speedy evaluation of the material's condition and processing history can be obtained through the use of hardness testing.

Surface inspection is the process of locating flaws that may have an impact on either performance or attractiveness. Scratch marks, stains, and mechanical damage can all be identified by visual inspection. Ultrasonic testing is one example of an advanced technique that can be used to identify internal discontinuities in crucial applications.

A supplier's dedication to quality management systems can be demonstrated by the ISO 9001:2015 certification designation. Through the implementation of this certification, the supply chain will be guaranteed to have uniform procedures, documentation management, and policies for continuous improvement.

Cost Optimization Strategies

Through careful planning of material consumption, the yield from conventional sheet sizes can be maximized. Through the use of nesting software, cutting patterns can be optimized to reduce waste. When it comes to pricing, standard measurements often offer better deals than custom dimensions due to the increased efficiency of production.

It is possible to achieve significant cost savings through economies of scale when purchasing in large quantities. Obtaining favorable pricing and priority delivery can be accomplished through the use of annual agreements with approved suppliers. While still allowing for flexibility, blanket orders allow for bulk discounts to be maintained.

Location of processing has an impact on total project costs that goes beyond the prices of raw materials. Processing that is done locally cuts down on both lead times and transportation costs. The presence of specialist capabilities, on the other hand, may justify shipping to remote sites alongside the required expertise.

Inventory management involves weighing the expenses of carrying inventory against the requirements for availability. Although just-in-time supply lowers the amount of working capital that is required, it may result in higher unit costs. The optimization of both cost and availability can be achieved through the strategic inventory of widely utilized grades and sizes.

Supplier Selection Criteria

Expertise in technical matters guarantees the correct selection of materials and support for applications. In addition to providing helpful advice on grade selection, processing recommendations, and problem-solving capabilities, experienced suppliers also offer valuable guidance. The application of metallurgical expertise can help maximize the performance of materials for certain applications.

The verification of quality systems provides protection against problems with delivery and flaws in the materials. Conducting audits of suppliers ensures that they are capable and that they comply with quality requirements. Reference consumers offer perceptions into the real performance and dependability of a product or service.

Reliability in the supply chain has an impact on the scheduling of projects and the planning of production. There is protection against disruptions in supply when multiple sourcing choices are available. When it comes to multinational projects that require coordinated deliveries, global suppliers provide a number of advantages.

The overall complexity and price of a project are both reduced by value-added services. The supply chain is simplified through the use of services such as custom cutting, surface treatments, and packing. It is possible to avoid costly mistakes by providing technical support during the design and manufacturing phases.

Conclusion

Successful pure titanium sheet selection requires balancing material properties, dimensional requirements, quality standards, and cost considerations. Understanding grade differences, processing capabilities, and supplier qualifications ensures optimal results for your specific application. The investment in proper material selection pays dividends through improved performance, extended service life, and reduced maintenance requirements. Working with experienced suppliers who understand your industry requirements and provide comprehensive technical support maximizes project success while minimizing risks and delays.

Partner with Chuanghui Daye for Premium Pure Titanium Sheet Solutions

Shaanxi Chuanghui Daye delivers high-quality commercially pure titanium sheets with complete traceability and fast delivery capabilities. Located in China's Titanium Capital, our advanced manufacturing facilities and ISO 9001:2015 certification ensure consistent quality for your critical applications. As a trusted pure titanium sheet manufacturer with over 30 years of industry expertise, we provide competitive factory-direct pricing and comprehensive technical support. Contact us at info@chdymetal.com to discuss your project requirements and receive detailed quotations.

References

1. Boyer, R., Welsch, G., & Collings, E.W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

2. Lutjering, G., & Williams, J.C. (2007). Titanium: Engineering Materials and Processes. Springer-Verlag Berlin Heidelberg.

3. American Society for Testing and Materials (2021). ASTM B265-20 Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate. ASTM International.

4. Donachie, M.J. (2000). Titanium: A Technical Guide, Second Edition. ASM International.

5. International Organization for Standardization (2019). ISO 5832-2:2018 Implants for Surgery - Metallic Materials - Part 2: Unalloyed Titanium. ISO.

6. Aerospace Material Specification (2020). AMS 4902R: Titanium Alloy Sheet, Strip, and Plate Unalloyed, Annealed. SAE International.