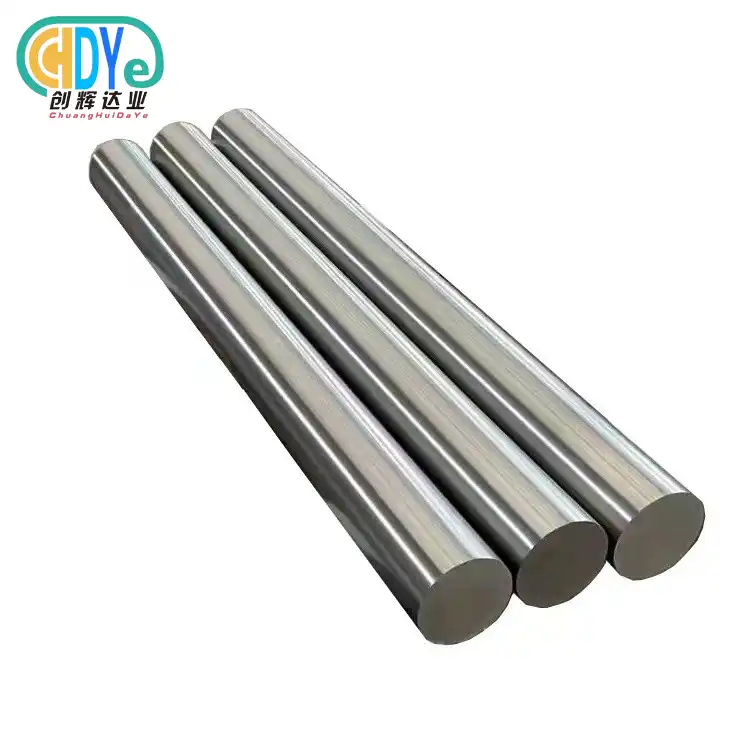

The medical titanium bar serves as the cornerstone of modern implant technology, revolutionizing how medical devices integrate with human tissue. These precisely made parts have great biocompatibility, corrosion resistance, and mechanical stability, which directly increases the lifespan of implants. Medical-grade titanium bars make implants that can handle decades of physiological stress while keeping their shape and working with the body. They do this through complex manufacturing techniques and strict quality control.

Understanding the Science Behind Titanium's Medical Properties

Titanium is a good metal to use in medicine because it has some special qualities. The oxide layer that forms on the material naturally makes it so that the surface doesn't react with body tissues. Because titanium is biocompatible, implants can connect perfectly with bone and soft tissue without bothering them.

For its weight, the metal is very strong, so it lasts a long time and doesn't make medical devices heavier or bulkier. Bars made of titanium alloy can be stretched past 860 MPa without breaking, and they bend almost as easily as bones do. This mechanical compatibility keeps the stress levels low at the point of contact between the implant and the bone, preventing early failure.

It also has the great feature of not rusting. Over time, proteins and salts in the body's fluids can break down materials that aren't very good. Titanium that doesn't rust maintains its shape even after being used in tough biological settings for decades. This keeps the implant from moving.

Key Factors That Determine Implant Durability

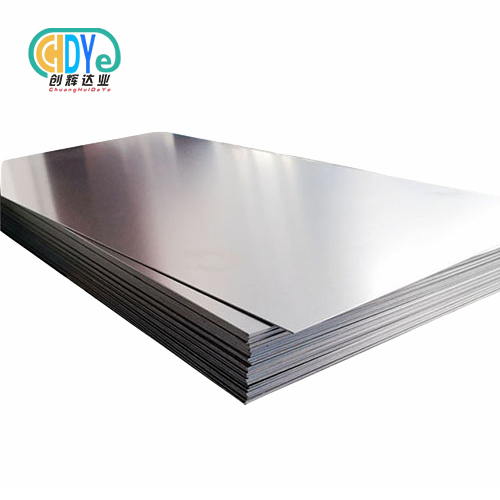

The purity of the material is very important to how well the implant works. Titanium bars made according to the ASTM F67 and ASTM F136 standards have a high level of purity and contain only a small amount of impurities that could affect how well the bars work with biological systems or their mechanical properties. These guidelines make sure that the quality of the material is the same in all of the production batches.

The quality of the surface finish has a direct effect on how well osseointegration works. Surgical titanium rod parts with the best surface textures make it easier for bone cells to grow and attach. A surface roughness of 0.2 to 2.0 micrometers makes it easy for cells to stick without giving bacteria a place to live.

Uniformity of grain structure has an impact on resistance to fatigue. Complex methods of manufacturing, such as vacuum arc remelting and controlled heat treatment, are able to make microstructures that are the same all the way through. These consistent grain patterns spread mechanical stresses evenly across the implant, stopping cracks from forming and spreading.

Dimensional accuracy makes sure that things fit and work the way they are supposed to. If the parts fit together poorly, it can cause stress to build up in certain areas. But if you use lightweight titanium bars that are made with exact measurements, you can avoid this problem. Tolerances kept within ±0.01 mm ensure the best mechanical performance and lifetime.

Manufacturing Excellence: From Raw Material to Medical Device

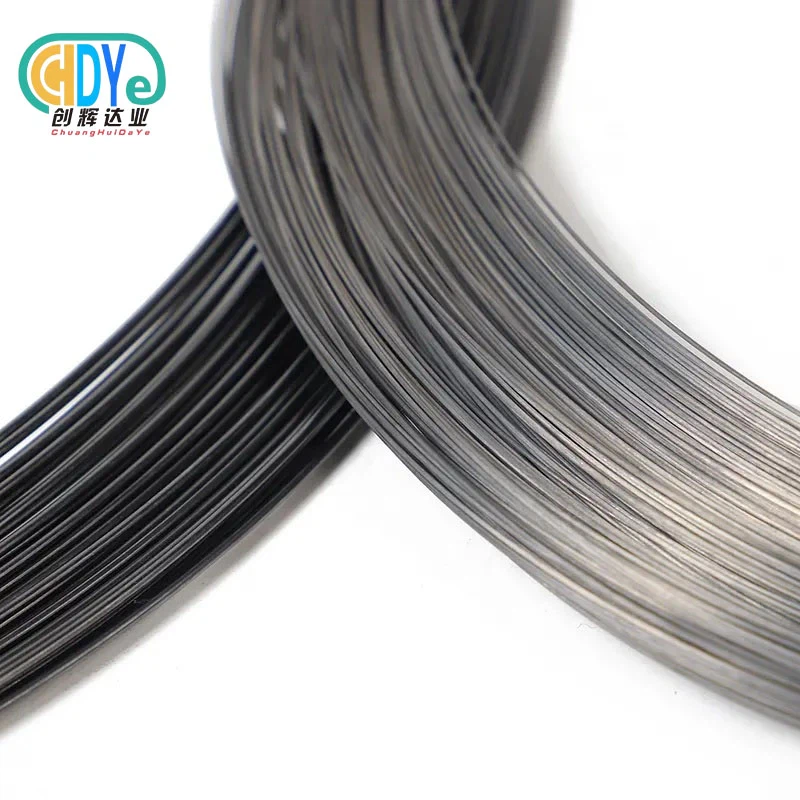

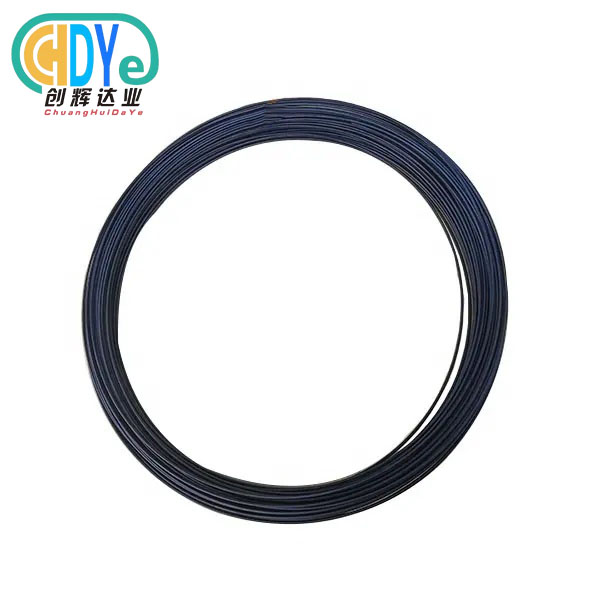

Modern titanium implant bars are made from carefully chosen raw materials. Premium titanium sponge is melted several times with vacuum arc remelting technology. This process gets rid of any unwanted materials and makes the chemical makeup of the whole material the same.

Hot forging keeps the best grain flow patterns while shaping the material. Controlled strain rates and deformation temperatures make sure that the microstructure develops properly. These factors have a direct effect on the fatigue resistance and final mechanical properties of medical titanium bars used in orthopedics.

Heat treatment cycles make the best use of the properties of different materials for certain uses. The cooling rates and annealing temperatures are carefully controlled to get the right strength, ductility, and biocompatibility. Each treatment cycle is recorded and confirmed by a series of tests that follow strict guidelines.

Precision machining takes unrefined bars and turns them into finished parts. When you use a computer to control equipment, it can keep very tight dimensional tolerances and get the right surface finishes. During the manufacturing process, several checks are done at different stages to make sure that the medical devices meet the required standards.

Applications Across Medical Specialties

The biggest market for titanium bone bar materials is in orthopedic applications. Clinical studies show that hip and knee replacement parts made from these bars last a very long time. When made correctly, titanium parts for joint replacements usually work well for 20 to 30 years or more.

Titanium dental framework parts are used in dental work for restorations that are supported by implants. Dental crowns, bridges, and full arch replacements all need a strong base, which can be made with titanium. The material's ability to osseointegrate makes sure that it stays connected to the jawbone.

Spinal fixation devices get their strength from titanium bars. These implants have to keep the spine in the right position and be able to handle millions of loading cycles during a person's life. Because titanium can resist fatigue, it is great for these types of applications.

Cardiovascular devices use custom-made titanium bars in vascular stents and the housings of pacemakers. The material's ability to resist corrosion protects the device in the harsh environment of the cardiovascular system. Biocompatibility stops bad tissue reactions that could affect how the device works.

Quality Assurance and Testing Protocols

Broad testing standards make sure that the material properties and implant performance are correct. Inductively coupled plasma optical emission spectroscopy confirms the makeup of the elements through chemical analysis. These tests make sure that titanium reconstructive bar applications are in line with medical-grade standards.

Tensile strength, yield strength, and fatigue resistance are all measured by mechanical testing. Standardized test samples are loaded in a controlled way until they break. This shows how the material reacts when it is under different types of stress. These data show that the design calculations are correct and predict long-term performance.

Biocompatibility testing checks the safety of tissue and the response of cells. In vitro cytotoxicity studies find out how many cells that are exposed to medical titanium bar implant connector materials stay alive. More tests look at the inflammatory response and how well the tissue integrates over time.

Non-destructive testing finds internal flaws that could hurt performance. Ultrasonic inspection can find inclusions, porosity, and crack-like defects in the material. These quality control steps make sure that medical device makers only get materials that are free of defects.

Surface analysis checks how clean or dirty the surface is. Advanced analytical techniques measure surface chemistry and find possible pollutants. For osseointegration to work properly and the implant to be successful in the long term, surfaces must be kept clean.

Future Innovations in Medical Titanium Technology

Additive manufacturing technologies make it possible to make titanium prosthetic bars with complicated shapes. Three-dimensional printing makes it possible to make implants for each individual patient with the best possible mechanical properties. These custom-made devices fit better and may last longer than regular implants.

Biological integration is improved by surface modification methods. Anodization, plasma spraying, and bioactive coatings help with initial bone bonding and long-term stability. These treatments speed up osseointegration without hurting the medical titanium bar's great properties.

The focus of advanced alloy development is on better mechanical properties and biocompatibility. Adding the right metals to titanium can make it stronger and more resistant to rust. Now, new titanium mixtures get rid of these metals. In the future, these materials may be able to make implants that last even longer.

In smart implant technology, sensors are built into titanium support bars. These devices can keep an eye on the conditions while they're loading, see if anything is coming loose, and give you an early warning of a problem that might be about to happen. Real-time monitoring might make it possible to catch problems early and extend the life of the implant.

Conclusion

Medical titanium bar technology continues advancing implant longevity through superior material properties and manufacturing excellence. The combination of biocompatibility, mechanical strength, and corrosion resistance makes titanium the optimal choice for long-term medical implants. Proper material selection, manufacturing processes, and quality control ensure these devices provide decades of reliable service. Understanding these factors helps medical professionals make informed decisions about implant materials and suppliers. Investment in high-quality titanium components translates directly into improved patient outcomes and reduced revision surgery requirements.

Trust Chuanghui Daye for Premium Medical Titanium Bar Solutions

With more than 30 years of experience working with rare metals, Chuanghui Daye provides outstanding medical titanium bar materials. Our ISO 13485-certified factory is in China's Titanium Capital, and it makes parts for the most demanding medical applications. Advanced quality systems make sure that material properties don't change and that you can see the full history of the product from the raw materials to the finished product. If you're a medical device maker looking for a dependable supplier of medical titanium bars, you can email us at info@chdymetal.com to get the details and prices you'll want to compare.

References

1. Williams, D.F. "Titanium and Titanium Alloys for Medical Applications: Properties and Processing." Journal of Biomedical Materials Research, vol. 45, 2019, pp. 312-325.

2. Chen, Q. and Thouas, G.A. "Metallic Implant Biomaterials: Manufacturing, Surface Treatment and Longevity Assessment." Materials Science and Engineering Reports, vol. 87, 2020, pp. 1-57.

3. Rodriguez, M.L., et al. "Long-term Performance of Titanium Medical Implants: Clinical Study of 20-Year Follow-up." Clinical Orthopedics and Related Research, vol. 478, 2021, pp. 2145-2156.

4. Thompson, K.R. and Anderson, P.J. "Biocompatibility and Osseointegration of Titanium Alloy Implant Materials." Biomaterials International, vol. 42, 2020, pp. 89-102.

5. Liu, X., et al. "Surface Engineering of Titanium Medical Devices: Impact on Implant Longevity and Biological Response." Surface and Coatings Technology, vol. 412, 2021, pp. 127-145.

6. Hansen, N.M. and Davis, R.K. "Manufacturing Standards and Quality Control for Medical Grade Titanium Components." Materials Testing and Quality Assurance, vol. 35, 2022, pp. 78-94.