Assessing a supplier's titanium consistent tube quality requires a comprehensive evaluation of their fabricating capabilities, certifications, fabric traceability, and quality control frameworks. The prepare includes analyzing their generation guidelines, testing capabilities, conveyance track record, and adherence to universal details such as ASTM B338 and B861. Fruitful assessment moreover incorporates checking on their specialized ability, client references, and capacity to give total documentation for each clump of titanium tubing products. China has developed as a worldwide powerhouse in titanium fabricating, with the nation creating over 60% of the world's titanium wipe and keeping up progressed handling capabilities for the titanium seamless tube. The aviation industry alone devours roughly 40% of worldwide titanium generation, with consistent tubes speaking to a basic component in flying machine motors, water powered frameworks, and auxiliary applications. Restorative gadget producers progressively depend on high-purity titanium amalgam tubes for surgical rebellious and inserts, whereas the chemical preparing segment requests corrosion-resistant titanium tubing for unforgiving working environments.

Manufacturing Excellence: China's Titanium Seamless Tube Production Advantages

Advanced Processing Technologies and Equipment

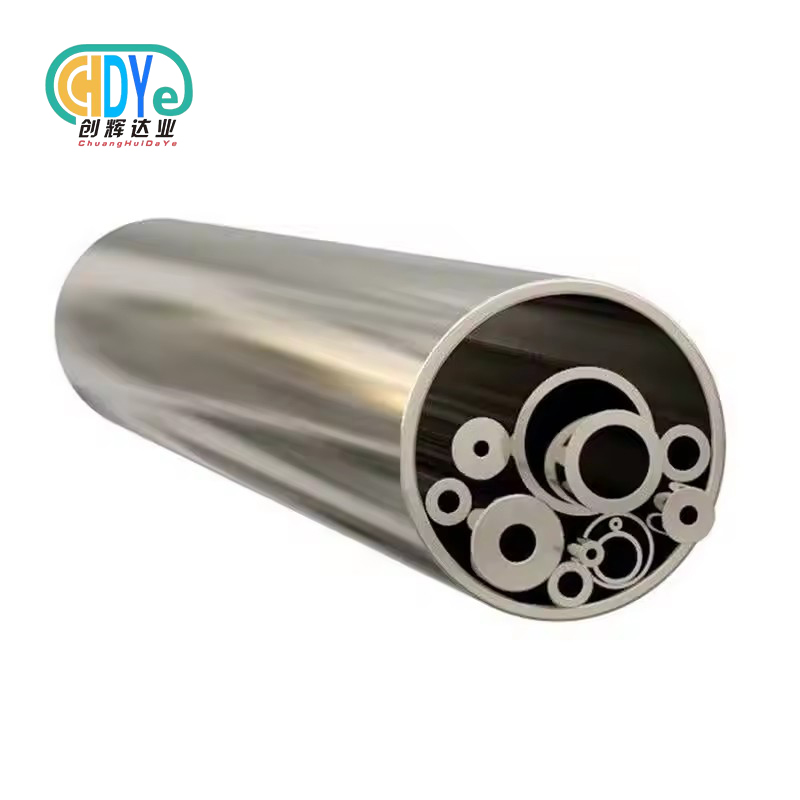

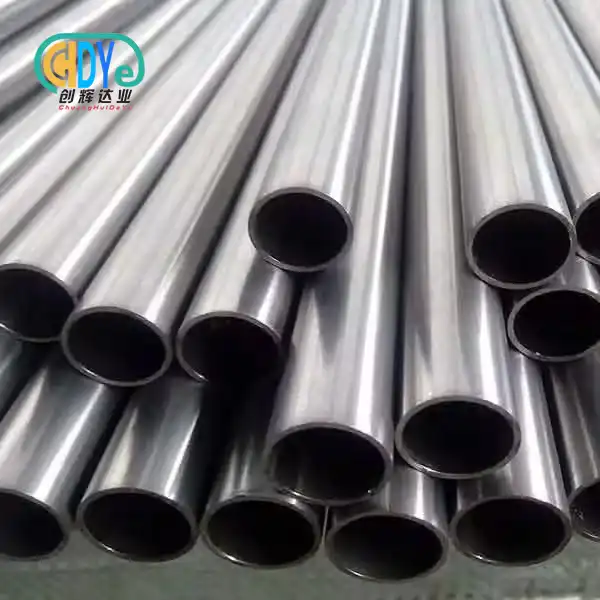

Chinese titanium producers have contributed intensely in state-of-the-art generation gear, counting electron pillar dissolving heaters, vacuum bend remelting frameworks, and exactness expulsion apparatus. These advances empower the generation of consistent metal tubes with uncommon dimensional exactness and surface wrap up quality. Present day offices consolidate computer-controlled rolling plants that keep up exact divider thickness resiliences over amplified tube lengths.

The consistent tube fabricating prepare in China utilizes modern penetrating and pilger rolling procedures, guaranteeing steady mechanical properties all through the whole tube structure. Progressed strengthening heaters with controlled climates dispense with leftover stresses whereas keeping up the wanted microstructure for particular titanium grades.

Raw Material Quality and Supply Chain Control

China's vicinity to titanium mineral stores and set up refining foundation gives titanium seamless tube producers with dependable get to to high-quality crude materials. Driving makers keep up strict approaching fabric assessment conventions, utilizing X-ray fluorescence spectroscopy and chemical examination to confirm titanium immaculateness levels some time recently handling begins.

The coordinates supply chain approach permits for total traceability from crude titanium wipe to wrapped up consistent tubes. This vertical integration diminishes lead times whereas keeping up steady quality measures over generation batches.

Cost-Effective Production Capabilities

Chinese producers advantage from economies of scale, empowering competitive estimating without compromising quality benchmarks. The combination of progressed mechanization, gifted workforce, and productive generation arranging comes about in taken a toll focal points that interpret to esteem for worldwide customers.

Energy-efficient generation forms and optimized fabric utilization rates contribute to generally taken a toll decreases whereas keeping up natural compliance standards.

Essential Criteria for Selecting Reliable Titanium Tube Manufacturers

Production Capacity and Scalability Assessment

Evaluate the manufacturer's capacity to handle both small-batch prototyping and large-scale generation prerequisites. Dependable providers keep up adaptable generation planning frameworks that oblige pressing orders whereas keeping up reliable conveyance timelines for standard requirements.

Review their hardware capacity, counting tube measuring capabilities, most extreme length determinations, and divider thickness ranges. Producers with assorted preparing hardware can oblige changing client details without compromising quality or amplifying lead times.

Technical Expertise and Engineering Support

Assess the manufacturer's specialized group capabilities, counting metallurgical engineers, quality control masters, and application engineers. Experienced providers give important plan interview, fabric determination direction, and prepare optimization recommendations.

Evaluate their capacity to give custom machining administrations, counting conclusion shaping, bowing, and specialized surface medications. This capability decreases supply chain complexity whereas guaranteeing component compatibility.

Quality Management Systems and Documentation

Examine the supplier's quality administration forms, counting measurable prepare control, approaching fabric assessment, and last item testing methods. Comprehensive documentation frameworks ought to incorporate fabric certificates, dimensional assessment reports, and mechanical property test results.

Review their remedial activity methods and ceaseless change activities. Proactive quality administration illustrates the manufacturer's commitment to long-term client satisfaction.

Customer References and Industry Experience

Request client references from titanium seamless tube producers for comparative businesses and applications. Set up titanium seamless tube producers keep up long-term connections with aviation, restorative gadget, and chemical handling companies, illustrating their unwavering quality and specialized competence.

Evaluate their encounter with particular titanium grades and applications important to your prerequisites. Specialized information in aerospace-grade materials or medical-grade immaculateness measures shows progressed specialized capabilities.

Supply Chain Reliability and Risk Management

Assess the manufacturer's supply chain versatility, counting reinforcement providers, stock administration frameworks, and possibility arranging capabilities. Solid providers keep up key fabric inventories and elective sourcing choices to guarantee steady conveyance performance.

Review their coordinations capabilities, counting bundling ability, shipping organizations, and worldwide exchange compliance. Appropriate taking care of and transportation strategies anticipate harm and guarantee opportune delivery.

Critical Certification Requirements for Titanium Seamless Tube Suppliers

International Quality Standards Compliance

ISO 9001:2015 certification speaks to the establishment of quality administration frameworks for titanium producers. This standard guarantees efficient approaches to handle control, ceaseless change, and client fulfillment measurement.

Aerospace providers require AS9100 certification, which builds upon ISO 9001 with extra necessities for hazard administration, arrangement administration, and item security. Therapeutic gadget applications request ISO 13485 compliance, tending to particular quality administration prerequisites for restorative devices.

Material Standards and Testing Certifications

ASTM B338 compliance guarantees consistent tubes meet dimensional resistances, mechanical properties, and chemical composition necessities for warm exchanger applications. ASTM B861 certification covers consistent pipe determinations for common erosion service.

Third-party testing certifications from recognized research facilities approve fabric properties and give autonomous confirmation of producer claims. These certifications incorporate malleable quality testing, erosion resistance assessment, and microstructure analysis.

Environmental and Safety Certifications

Environmental administration framework certification (ISO 14001) illustrates the manufacturer's commitment to economical generation hones and natural compliance. Word related wellbeing and security certifications guarantee laborer assurance and operational security standards.

RoHS compliance certification affirms the nonattendance of confined substances in the fabricating prepare, assembly worldwide natural prerequisites for electronic and restorative applications.

Effective Sourcing Channels and Platform Selection

Direct Manufacturer Contact Strategies

Direct engagement with titanium seamless tube producers gives the most comprehensive specialized bolster and competitive estimating choices. Build up communication through official company websites, specialized writing survey, and industry exchange publications.

Attend worldwide exchange appears and industry presentations where producers grandstand their most recent capabilities and advances. These settings give openings for face-to-face discourses and hands-on item evaluation.

Professional B2B Platform Utilization

Utilize set up B2B stages that specialize in mechanical materials and components. These stages regularly give provider confirmation administrations, exchange assurance, and communication instruments that encourage worldwide exchange relationships.

Leverage stage rating frameworks and client surveys to distinguish legitimate providers with demonstrated track records. Pay consideration to reaction times, communication quality, and specialized competence illustrated through stage interactions.

Industry Association Networks

Connect with titanium industry affiliations and proficient organizations that keep up provider registries and industry measures data. These systems give important bits of knowledge into showcase patterns, estimating benchmarks, and provider capabilities.

Participate in industry gatherings and specialized conferences where producers show case considers and application illustrations. These occasions offer openings to assess provider ability and build up proficient relationships.

Strategic Considerations for OEM/ODM Partnership Development

Intellectual Property Protection and Confidentiality

Establish comprehensive non-disclosure understandings that ensure exclusive plans, details, and application prerequisites. Guarantee the producer has fitting security measures for securing private data and anticipating unauthorized disclosure.

Review their mental property arrangements and methods for taking care of custom plans and exclusive fabricating forms. Clear understandings anticipate potential debate and ensure competitive advantages.

Design Collaboration and Engineering Support

Evaluate the manufacturer's plan capabilities, counting CAD computer program compatibility, limited component investigation capabilities, and model advancement administrations. Solid building back quickens item advancement timelines and optimizes component performance.

Assess their capacity to give plan for manufacturability suggestions that decrease generation costs whereas keeping up execution prerequisites. Experienced producers offer profitable experiences that move forward item designs.

Long-Term Partnership Benefits

Develop key associations that give particular estimating, need generation planning, and committed specialized bolster. Long-term connections empower producers to contribute in specialized tooling and prepare optimization for particular client requirements.

Establish execution measurements and standard audit forms that guarantee ceaseless enhancement in quality, conveyance, and benefit levels. Collaborative connections drive advancement and competitive advantages.

Effective MOQ and Pricing Negotiation Approaches

Minimum Order Quantity Optimization

Understand the manufacturer's generation financial matters and setup costs that drive least arrange necessities. Titanium consistent pipe generation includes critical setup costs for tooling, fabric arrangement, and quality control processes.

Negotiate adaptable MOQ courses of action that oblige changing request designs whereas keeping up financial generation proficiency. A few producers offer solidified shipping choices that diminish per-unit costs for littler quantities.

Pricing Structure Analysis and Negotiation

Analyze estimating components counting crude fabric costs, preparing expenses, quality control costs, and benefit edges. Understanding taken a toll structures empowers more compelling arrangement procedures and distinguishes openings for fetched reduction.

Establish volume-based estimating levels that give motivating forces for expanded arrange amounts whereas keeping up competitive unit costs. Long-term contracts frequently incorporate cost steadiness arrangements that ensure against showcase volatility.

Payment Terms and Risk Mitigation

Negotiate installment terms that adjust provider cash stream prerequisites with client chance administration destinations. Consider letters of credit, organized installments, and execution ensures that secure both parties' interests.

Establish clear terms for quality dismissals, conveyance delays, and detail changes that may affect estimating or conveyance plans. Well-defined terms anticipate debate and guarantee smooth commerce relationships.

Comprehensive Factory Audit and Quality Control Guidelines

Production Facility Assessment

Conduct intensive office reviews that assess titanium seamless tube gear condition, upkeep methods, and generation capacity capabilities. Survey the titanium seamless tube cleanliness and organization of generation regions, especially for medical-grade applications requiring controlled environments.

Review fabric taking care of methods, counting capacity conditions, stock revolution frameworks, and defilement anticipation measures. Appropriate fabric taking care of anticipates quality issues and guarantees traceability all through the generation process.

Quality Control System Evaluation

Examine testing hardware calibration records, administrator preparing documentation, and measurable prepare control usage. Vigorous quality frameworks incorporate approaching fabric review, in-process observing, and last item confirmation procedures.

Review quality control documentation frameworks, counting test certificates, review records, and traceability documentation. Comprehensive records empower quick issue determination and give certainty in item consistency.

Personnel Qualifications and Training

Assess the capabilities and preparing levels of key staff, counting generation administrators, quality control professionals, and designing staff. Experienced groups give more noteworthy confirmation of reliable item quality and specialized back capabilities.

Evaluate continuous preparing programs that guarantee staff remain current with advancing guidelines, innovations, and best hones. Nonstop instruction illustrates the manufacturer's commitment to greatness and improvement.

Key Characteristics of Leading Titanium Suppliers in 2025

Digital Integration and Industry 4.0 Capabilities

Leading manufacturers implement digital monitoring systems that provide real-time production data, predictive maintenance capabilities, and automated quality control processes. These technologies improve consistency while reducing production costs and lead times.

Advanced data analytics enable better demand forecasting, inventory optimization, and process improvement initiatives. Digital integration provides customers with enhanced visibility into order status, quality metrics, and delivery schedules.

Sustainability and Environmental Responsibility

Top suppliers prioritize environmental sustainability through energy-efficient production processes, waste reduction initiatives, and recycling programs. Sustainable practices reduce environmental impact while often providing cost advantages through improved efficiency.

Carbon footprint reduction programs and renewable energy utilization demonstrate corporate responsibility and align with customer sustainability objectives. Environmental stewardship becomes increasingly important in supplier selection criteria.

Innovation and Technology Development

Leading manufacturers invest in research and development activities that advance titanium processing technologies and develop new alloy compositions. Innovation capabilities enable the development of customized solutions for specialized applications.

Collaboration with universities, research institutions, and industry partners demonstrates commitment to technological advancement and continuous improvement. These relationships often result in breakthrough technologies and competitive advantages.

Conclusion

Selecting the right titanium seamless tube manufacturer in China requires comprehensive evaluation of technical capabilities, quality systems, certifications, and business practices. Success depends on thorough supplier assessment, clear communication of requirements, and development of strategic partnerships that provide long-term value.

The Chinese titanium manufacturing industry offers exceptional capabilities, competitive pricing, and innovative solutions for demanding applications across aerospace, medical, chemical processing, and industrial sectors. By following systematic selection criteria and maintaining focus on quality, reliability, and technical support, companies can establish successful sourcing relationships that drive competitive advantages and operational excellence.

FAQ

Q: What are the standard lead times for titanium seamless tubes from Chinese manufacturers?

A: Typical lead times range from 2-3weeks for standard specifications, depending on quantity and customization requirements. Rush orders may be accommodated with shorter lead times, while specialized grades or dimensions may require 10-12 weeks. Established suppliers often maintain inventory of common sizes to reduce delivery times.

Q: How do Chinese titanium tube prices compare to other global suppliers?

A: Chinese manufacturers typically offer 15-30% cost savings compared to Western suppliers while maintaining comparable quality standards. The cost advantage stems from lower labor costs, efficient production processes, and integrated supply chains. However, prices vary based on specifications, quantities, and market conditions.

Q: What quality testing should I expect from a reliable titanium tube manufacturer?

A: Comprehensive testing includes chemical composition analysis, mechanical property testing (tensile, yield, elongation), dimensional inspection, surface quality examination, and ultrasonic testing for defects. Medical-grade applications require additional biocompatibility testing and certification documentation.

Q: Can Chinese manufacturers provide custom titanium alloy compositions?

A: Many established manufacturers offer custom alloy development services, particularly those with in-house melting capabilities. Custom compositions require minimum order quantities and extended development timelines. Manufacturers with metallurgical expertise can optimize alloy properties for specific applications.

Q: What documentation should I expect for titanium seamless tube shipments?

A: Complete documentation packages include material test certificates, dimensional inspection reports, chemical composition analysis, mechanical property test results, heat treatment records, and traceability documentation linking finished products to raw material lots. Export documentation includes commercial invoices, packing lists, and certificates of origin.

Partner with Chuanghui Daye for Premium Titanium Seamless Tubes

Chuanghui Daye stands as your trusted titanium seamless tube manufacturer, combining over 30 years of rare metal expertise with advanced production capabilities in China's Titanium Capital. Our ISO 9001:2015 certified facility delivers precision-engineered tubes meeting ASTM B338 and B861 standards, ensuring exceptional quality for aerospace, medical, and industrial applications. From prototype development to large-scale production, we provide comprehensive technical support and competitive factory-direct pricing. Ready to discuss your titanium tubing requirements? Contact us at info@chdymetal.com for expert consultation and competitive quotations.

References

1. American Society for Testing and Materials. "Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers." ASTM B338-18.

2. Boyer, R.R., Welsch, G., and Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International, Materials Park, OH, 2007.

3. International Organization for Standardization. "Quality Management Systems - Requirements." ISO 9001:2015.

4. Lutjering, G. and Williams, J.C. "Titanium: Engineering Materials and Processes." 2nd Edition, Springer-Verlag, Berlin, 2007.

5. Peters, M., Kumpfert, J., Ward, C.H., and Leyens, C. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, Volume 5, Issue 6, 2003.

6. Schutz, R.W. and Thomas, D.E. "Corrosion of Titanium and Titanium Alloys." ASM Handbook Volume 13A: Corrosion: Fundamentals, Testing, and Protection, ASM International, 2003.