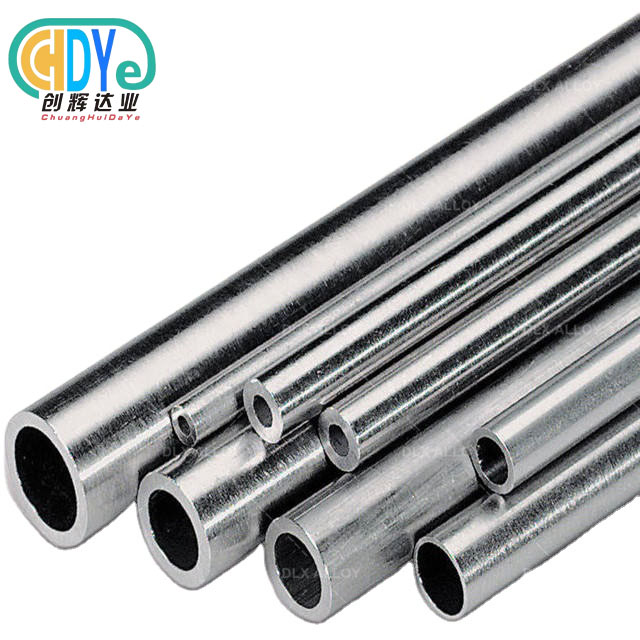

Finding reliable sources for GR2 titanium pipe with proper Mill Test Certificates requires careful consideration of supplier credentials, quality standards, and certification processes. Professional manufacturers like Shaanxi Chuanghui Daye Metal Material Co., Ltd., located in China's "Titanium Capital," offer certified GR2 titanium tubes with complete documentation including ASTM B861 compliance and ISO 9001:2015 certification. These suppliers provide comprehensive mill test certificates that verify chemical composition, mechanical properties, and dimensional specifications, ensuring your projects meet the highest industrial standards.

Understanding GR2 Titanium Pipe Applications and Market Demand

Key Applications Driving Global Demand

GR2 titanium tubing serves basic parts over numerous businesses due to its remarkable erosion resistance and mechanical properties. Chemical preparing offices depend intensely on these materials for warm exchangers, condensers, and reactor frameworks where forceful chemicals would quickly debase ordinary materials.

The aviation division proceeds extending its utilize of GR2 titanium consistent pipe for water powered frameworks, fuel lines, and auxiliary components. Restorative gadget producers progressively indicate GR2 titanium amalgam pipe for surgical rebellious and implantable gadgets, taking advantage of its biocompatibility and quality characteristics.

Marine applications speak to another critical showcase section, with desalination plants and seaward stages requiring GR2 titanium pipe determinations that withstand saltwater erosion over decades of benefit. Control era offices utilize these materials in condenser frameworks where unwavering quality specifically impacts operational efficiency.

Market Growth Factors and Regional Variations

Global demand for GR2 titanium tubing reflects broader industrial expansion patterns. Asia-Pacific markets show particularly strong growth driven by chemical processing infrastructure development and expanding aerospace manufacturing capabilities.

European markets emphasize medical-grade applications and precision engineering requirements, often requiring specialized GR2 titanium pipe dimensions and enhanced documentation standards. North American demand centers around aerospace applications and energy sector projects requiring long-term corrosion resistance.

Supply chain considerations increasingly influence purchasing decisions, with buyers seeking suppliers capable of providing consistent quality, reliable delivery schedules, and comprehensive technical support throughout project lifecycles.

Advantages of GR2 Titanium Pipe in Industrial Applications

Superior Material Properties

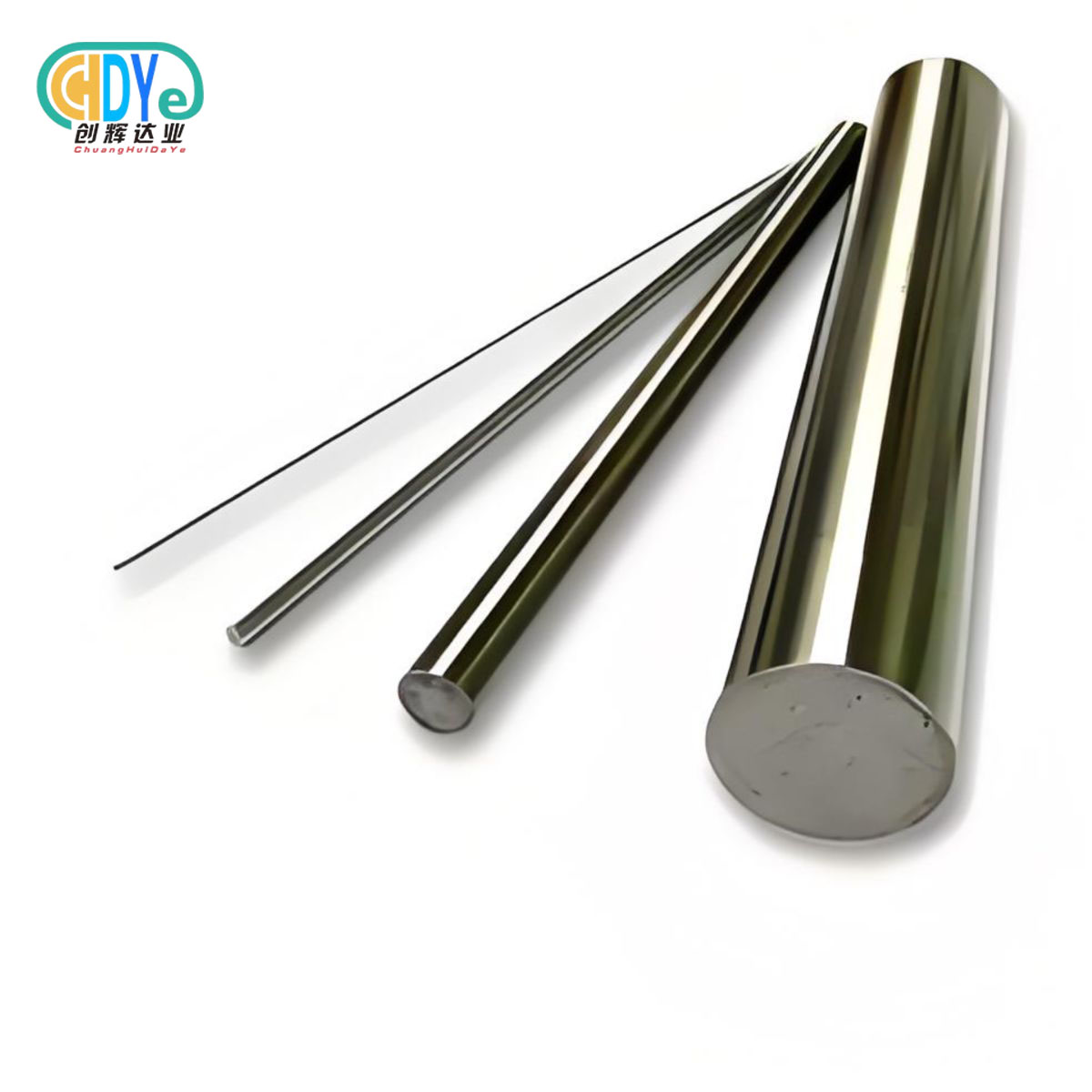

GR2 titanium pipe strength characteristics make it an ideal choice for demanding applications where conventional materials fail prematurely. The material exhibits excellent ductility while maintaining structural integrity under stress, allowing complex fabrication operations without compromising performance.

Corrosion resistance represents the most compelling advantage of GR2 titanium pipe applications. Unlike stainless steel or carbon steel alternatives, titanium forms a protective oxide layer that regenerates automatically when damaged, providing virtually unlimited service life in many environments.

The low density of titanium delivers significant weight savings compared to steel alternatives, particularly valuable in aerospace and marine applications where weight reduction translates directly to improved performance and fuel efficiency.

Processing and Fabrication Benefits

GR2 titanium pipe welding characteristics allow for reliable joining using standard TIG, MIG, and plasma welding techniques. Proper welding procedures maintain the base material's corrosion resistance and mechanical properties throughout the heat-affected zone.

Machining operations proceed smoothly with appropriate tooling and cutting parameters, enabling production of complex components and custom fittings. The material's work-hardening characteristics require specific techniques but allow for cold forming operations that would crack other materials.

Heat treatment options provide flexibility in optimizing mechanical properties for specific applications, though GR2 titanium pipe properties in the annealed condition often meet requirements without additional processing.

Global Supply Chain Analysis for Titanium Materials

Regional Manufacturing Capabilities

Global request for GR2 titanium tubing reflects broader mechanical development designs. Asia-Pacific markets appear especially solid development driven by chemical handling framework improvement and extending aviation fabricating capabilities.

European markets emphasize medical-grade applications and exactness building necessities, regularly requiring specialized GR2 titanium pipe measurements and upgraded documentation benchmarks. North American request centers around aviation applications and vitality division ventures requiring long-term erosion resistance.

Supply chain contemplations progressively impact acquiring choices, with buyers looking for providers competent of giving reliable quality, solid conveyance plans, and comprehensive specialized back all through extend lifecycles.

Supply Chain Considerations and Risk Management

Diversifying provider connections makes a difference moderate dangers related with single-source conditions. Effective obtainment techniques frequently include qualifying numerous GR2 titanium pipe producers over distinctive geographic regions.

Inventory administration gets to be pivotal given the specialized nature of titanium materials and longer lead times compared to product metals. Vital buyers regularly keep up security stock levels to maintain a strategic distance from extend delays.

Quality consistency shifts essentially between providers, making provider review forms and continuous quality checking basic components of fruitful acquirement programs.

Comparing Sourcing Channels for Titanium Materials

Direct Manufacturer Relationships

| Channel Type | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Direct Manufacturers | Best pricing, custom specifications, technical support | Higher MOQs, longer lead times | Large orders, custom requirements |

| Authorized Distributors | Local inventory, smaller quantities, faster delivery | Higher costs, limited customization | Standard sizes, urgent requirements |

| B2B Platforms | Multiple suppliers, price comparison, global reach | Quality verification challenges, communication barriers | Market research, supplier identification |

| Trading Companies | Consolidated sourcing, local support | Additional markup, limited technical expertise | Small to medium orders, simplified procurement |

Evaluating Channel Effectiveness

Direct producer connections regularly give the most comprehensive specialized back and competitive GR2 titanium pipe estimating for considerable orders. These associations empower collaborative advancement of details and long-term supply agreements.

Authorized merchants serve profitable parts for support, repair, and operations (MRO) prerequisites where prompt accessibility exceeds taken a toll contemplations. Numerous merchants keep up certified fabric stock with appropriate process test certificates.

B2B stages encourage provider revelation and advertise inquire about but require cautious confirmation of provider qualifications and quality capabilities. These stages work best for starting provider recognizable proof or maybe than continuous obtainment relationships.

Supplier Verification and Quality Control Guidelines

Essential Certification Requirements

ISO 9001:2015 certification speaks to the least quality administration standard for genuine GR2 titanium pipe providers. This certification illustrates precise quality control forms and ceaseless change practices.

ASTM standard compliance, especially ASTM B861 and ASTM B337, guarantees dimensional exactness and mechanical property conformance. Providers ought to give nitty gritty process test certificates recording chemical composition investigation and mechanical testing results.

Third-party quality reviews give extra certainty in provider capabilities, especially for basic applications where fabric disappointment seem have genuine consequences.

Practical Verification Steps

Request and survey later process test certificates to confirm testing strategies and documentation quality. True blue providers promptly give this data and clarify testing methodologies.

Conduct office reviews when conceivable, centering on dissolving gear, quality control research facilities, and fabric dealing with strategies. Advanced titanium preparing requires advanced gear and clean fabricating environments.

Implement approaching review methods for basic applications, counting free chemical investigation and mechanical testing confirmation. This approach approves provider claims and recognizes potential quality issues early.

Common Quality Control Points

Chemical composition confirmation guarantees GR2 titanium pipe chemical composition meets detail necessities, especially interstitial component substance that influences mechanical properties and erosion resistance.

Dimensional review affirms compliance with requested determinations, counting divider GR2 titanium pipe thickness resistances and straightness prerequisites basic for numerous applications.

Surface quality appraisal recognizes potential abandons that may compromise execution or complicate creation operations. Appropriate surface wrap up necessities shift by application but continuously influence last item quality.

Procurement Best Practices and Common Challenges

Order Planning and Specification Development

Minimum order quantities (MOQs) for GR2 titanium pipe dimensions typically range from 500 to 2,000 kilograms depending on size and specification complexity. Custom specifications often require higher MOQs to justify setup costs.

Lead times vary significantly based on material availability and processing requirements. Standard sizes might ship within 4-6 weeks, while custom specifications can require 12-16 weeks from order confirmation.

Payment terms typically involve 30-50% advance payment with balance due prior to shipment. Letters of credit provide security for both parties in international transactions but add complexity and cost.

Managing Common Procurement Challenges

Price volatility in titanium markets requires flexible procurement strategies and strong supplier relationships. Long-term agreements can provide price stability but may limit flexibility during market downturns.

Quality disputes arise most commonly from inadequate specification clarity or unrealistic expectations. Detailed specifications and pre-order samples help prevent misunderstandings.

Delivery delays often result from inadequate capacity planning or unexpected demand surges. Maintaining relationships with multiple qualified suppliers provides backup options when primary suppliers face constraints.

Cost Optimization Strategies

Consolidating orders across projects can achieve better GR2 titanium pipe price points while simplifying procurement administration. Annual agreements often provide volume discounts and priority scheduling.

Standardizing specifications across applications reduces inventory complexity and often enables better pricing through increased volume per specification.

Timing orders during supplier low-demand periods can sometimes achieve better pricing and shorter lead times, though this requires careful demand forecasting and inventory planning.

Conclusion

Sourcing GR2 titanium pipe with proper Mill Test Certificates requires careful supplier evaluation, clear specification development, and strategic relationship management. Success depends on understanding market dynamics, verifying supplier capabilities, and implementing robust quality control processes. Direct manufacturer relationships typically provide the best combination of pricing, technical support, and customization capabilities for substantial requirements. The global supply base offers numerous qualified suppliers, but thorough verification of certifications, production capabilities, and quality systems remains essential for critical applications. Effective procurement strategies balance cost considerations with quality requirements while maintaining supply chain flexibility.

FAQ

Q: What documentation should accompany GR2 titanium pipe purchases?

A: Essential documentation includes mill test certificates showing chemical composition analysis, mechanical property test results, dimensional inspection reports, and material traceability records. ASTM B861 compliance certificates and heat treatment records (when applicable) should also accompany shipments.

Q: How can buyers verify the authenticity of mill test certificates?

A: Verify certificates through independent testing of sample materials, requesting original laboratory reports with authorized signatures, and conducting supplier facility audits. Legitimate suppliers welcome verification activities and maintain detailed quality records.

Q: What are typical MOQs for GR2 titanium pipe orders?

A: MOQs typically range from 500-2,000 kg depending on pipe dimensions and specification requirements. Standard sizes often have lower MOQs, while custom specifications require higher minimum quantities to justify production setup costs.

Choose Chuanghui Daye as Your Trusted GR2 Titanium Pipe Manufacturer

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands out as a leading GR2 titanium pipe supplier offering comprehensive solutions for your industrial requirements. Located in China's Titanium Capital with over 30 years of industry expertise, we provide certified materials with complete mill test certificates and ISO 9001:2015 quality assurance. Our advanced manufacturing capabilities deliver custom specifications with competitive factory-direct pricing and reliable global delivery. Contact us at info@chdymetal.com to discuss your GR2 titanium pipe requirements and experience our commitment to quality excellence.

References

1. ASTM International. "Standard Specification for Seamless Titanium and Titanium Alloy Pipe." ASTM B861-20.

2. Boyer, R., Welsch, G., & Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International, Materials Park, OH.

3. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International.

4. Lütjering, Gerd, and James C. Williams. "Titanium: Engineering Materials and Processes." Springer-Verlag Berlin Heidelberg.

5. Peters, M., Kumpfert, J., Ward, C.H., & Leyens, C. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials.

6. Schutz, R.W., and Watkins, H.B. "Recent Developments in Titanium Alloy Application in the Energy Industry." Materials Science and Engineering.