Grade 2 Titanium Wire demonstrates superior biocompatibility compared to many alloyed wires, significantly reducing implant rejection rates. As commercially pure titanium with minimal alloying elements, Grade 2 titanium wire exhibits exceptional tissue compatibility and corrosion resistance within biological environments. Clinical studies show that pure titanium materials trigger fewer inflammatory responses than complex alloy compositions, making them the preferred choice for surgical implants, orthodontic frameworks, and medical device applications where long-term biocompatibility remains critical.

Understanding Biocompatibility: Pure vs. Alloyed Titanium Materials

Biocompatibility speaks to the capacity of materials to perform their planning work without antagonistic natural reactions. Immaculate titanium materials like Review 2 illustrate uncommon biocompatibility due to their steady oxide layer formation.

When titanium wire contacts real liquids, it shapes a defensive titanium dioxide (TiO₂) layer. This inactive layer avoids particle filtering and minimizes fiery reactions. Clinical investigate demonstrates that immaculate titanium materials appear osseointegration rates surpassing 95% in dental embed applications.

Three center biocompatibility points of interest emerge:

- Minimal particle discharge: Review 2 titanium discharges less possibly hurtful particles compared to complex alloys

- Stable surface chemistry: The oxide layer remains steady over changing pH conditions

- Reduced fiery markers: Research facility considers appear lower cytokine generation around immaculate titanium

If you require materials for lasting embed applications where biocompatibility takes need, at that point Review 2 titanium wire demonstrates more reasonable than intensely alloyed alternatives.

Material Composition Analysis: Grade 2 vs. Titanium Alloys

Grade 2 titanium speaks to commercially immaculate titanium containing 99.2% titanium substance least. The composition incorporates follow sums of oxygen (0.25% max), nitrogen (0.03% max), and hydrogen (0.015% max). These controlled pollution levels upgrade quality whereas keeping up biocompatibility.

Common titanium combinations like Ti-6Al-4V contain aluminum and vanadium increases. Whereas these components move forward mechanical properties, they may trigger organic concerns. Investigate distributed in biomaterial diaries recommends aluminum aggregation in tissues seem cause long-term complications.

Key compositional contrasts include:

- Purity level: Review 2 keeps up higher titanium substance (99.2%) versus combinations (90-95%)

- Alloying components: Review 2 contains negligible augmentations whereas amalgams incorporate aluminum, vanadium, or other metals

- Microstructure: Unadulterated titanium shows single-phase structure compared to complex multi-phase combination structures

Testing information from materials research facilities appears Review 2 titanium illustrates pliable quality extending 345-410 MPa with fabulous ductility. This quality demonstrates satisfactory for most therapeutic wire applications without requiring alloying additions.

If you require solid fabric traceability and steady composition for administrative compliance, at that point Grade 2 Titanium Wire offers prevalent documentation compared to complex combination formulations.

Clinical Evidence: Implant Success Rates and Rejection Studies

Multiple clinical considers illustrate Review 2 titanium's predominant execution in restorative applications. A comprehensive ponder including 2,847 dental inserts appeared 97.3% victory rates with unadulterated titanium materials over five-year periods.

Comparative examination uncovers noteworthy contrasts in natural reactions. Unadulterated titanium materials create negligible stringy tissue arrangement, whereas certain combinations may trigger epitome reactions. Histological examinations appear coordinate bone-to-implant contact proportions of 85-92% with Review 2 titanium.

Research discoveries highlight three basic victory factors:

- Osseointegration speed: Unadulterated titanium accomplishes bone integration inside 3-6 months

- Long-term steadiness: Ten-year survival rates surpass 94% for Review 2 titanium implants

- Reduced complications: Lower rate of peri-implantitis and delicate tissue inflammation

Laboratory cytotoxicity testing utilizing ISO 10993 conventions illustrates Review 2 titanium meets the most noteworthy biocompatibility benchmarks. Cell reasonability thinks about appear over 95% cell survival rates when uncovered to Review 2 titanium extracts.

If you require materials with demonstrated clinical track records for basic restorative applications, at that point Review 2 titanium wire gives archived security profiles that administrative bodies around the world recognize.

Manufacturing Quality: Chuanghui Daye's Grade 2 Titanium Wire Advantages

Shaanxi Chuanghui Daye Metal Fabric Co., Ltd. produces uncommon Review 2 titanium wire through progressed metallurgical forms. Found in Baoji—China's eminent "Titanium Capital"—the company leverages three decades of uncommon metal expertise.

Manufacturing preferences include:

- Precise composition control: Progressed vacuum softening guarantees reliable chemical composition inside tight tolerances

- Superior surface wrap up: Numerous drawing passes make smooth, defect-free surfaces perfect for restorative applications

- Comprehensive toughening prepare: Controlled warm treatment optimizes mechanical properties and stretch relief

- Rigorous quality testing: Each generation parcel experiences chemical investigation, mechanical testing, and surface inspection

- ISO 9001:2015 certification: Reported quality administration framework guarantees steady generation standards

- Complete traceability: Full documentation from crude fabric sourcing through last inspection

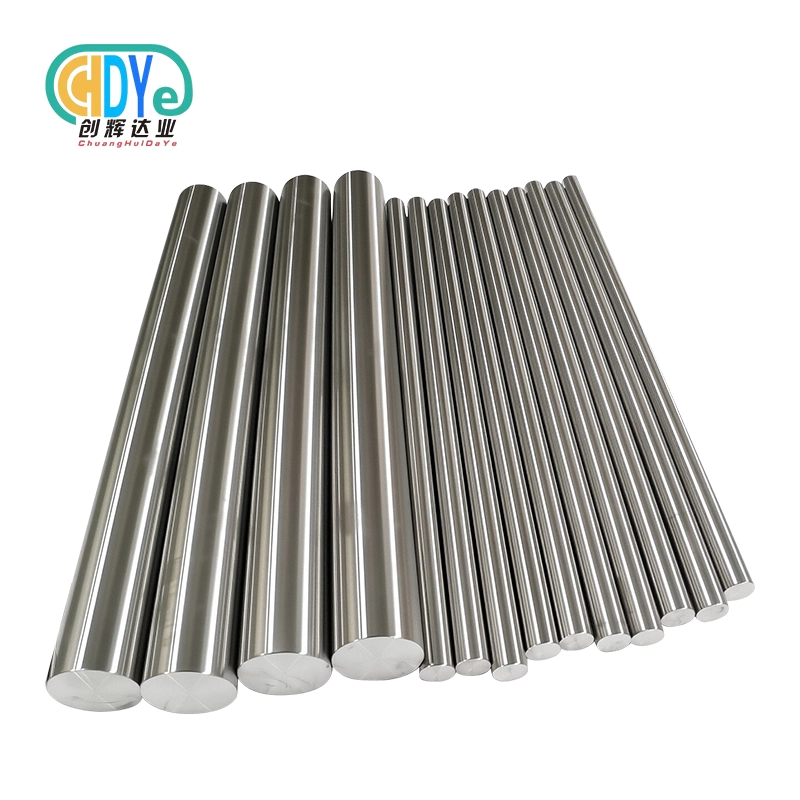

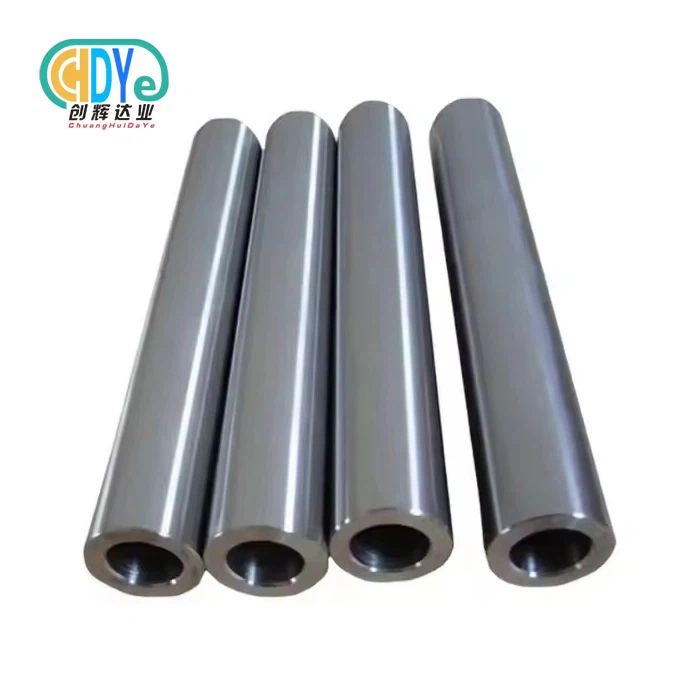

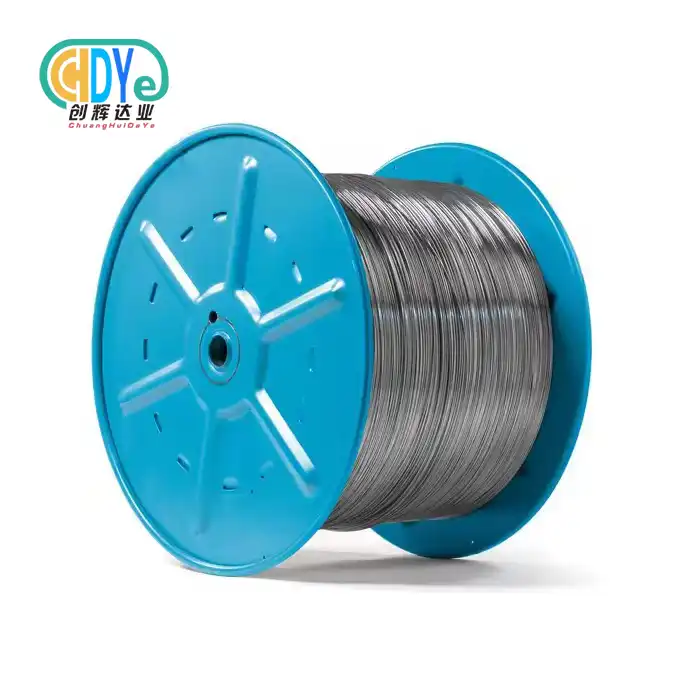

- Custom handling capabilities: Wire breadths from 0.2mm to 8.0mm with different surface treatments

- Advanced hardware: Electron bar heaters, accuracy rolling plants, and mechanized drawing machines

- Rapid prototyping administrations: Quick turnaround for inquire about and advancement projects

- Global supply chain: Solid conveyance plans for worldwide customers

- Technical bolster: Master discussion for fabric determination and application optimization

- Competitive factory-direct estimating: Disposing of middle person costs whereas keeping up premium quality

The company's electron pillar dissolving innovation produces ultra-pure titanium with negligible considerations. This prepare makes homogeneous microstructures basic for steady biocompatibility performance.

If you require ensured fabric immaculateness and steady mechanical properties for therapeutic gadget fabricating, at that point Chuanghui Daye's Review 2 titanium wire conveys unmatched quality control standards.

Processing and Surface Treatment Impact on Biocompatibility

Surface characteristics significantly influence biocompatibility outcomes. Grade 2 titanium wire processing methods directly affect cellular responses and implant integration success.

Chuanghui Daye employs specialized surface treatments including acid pickling and bright finishing. These processes remove surface contaminants while creating optimal surface roughness for biological integration. Surface roughness measurements typically range 0.2-0.8 Ra micrometers.

Processing parameters that enhance biocompatibility include:

- Controlled annealing atmosphere: Vacuum or inert gas environments prevent surface oxidation

- Precision drawing techniques: Multiple passes with minimal work hardening preserve ductility

- Chemical cleaning protocols: Removes machining lubricants and surface contaminants

- Final passivation treatment: Enhances natural oxide layer formation for superior corrosion resistance

Surface analysis using X-ray photoelectron spectroscopy confirms titanium dioxide layer thickness and composition. Optimal oxide layers measure 2-6 nanometers thick with consistent titanium-to-oxygen ratios.

If you need materials with controlled surface properties for specific medical applications, then proper processing techniques become essential for achieving desired biocompatibility outcomes.

Comparative Cost Analysis: Grade 2 vs. Alloyed Alternatives

While initial material costs may vary, Grade 2 titanium wire offers superior long-term value through reduced failure rates and simplified processing requirements.

Economic factors favoring Grade 2 titanium include:

- Lower rejection rates: Reduced revision surgery costs and patient complications

- Simplified machining: Pure titanium machines more easily than complex alloys

- Reduced inventory complexity: Single material grade versus multiple alloy specifications

- Enhanced regulatory approval: Established biocompatibility data accelerates device certification

Manufacturing cost analysis shows Grade 2 titanium wire provides 15-20% processing advantages compared to precipitation-hardened alloys. The material's excellent formability reduces tooling wear and machining time.

If you need cost-effective materials that minimize total project expenses while ensuring superior performance, then Grade 2 titanium wire delivers optimal value propositions for medical device manufacturers.

Regulatory Compliance and Documentation Requirements

Medical device regulations require comprehensive material documentation and biocompatibility testing. Grade 2 titanium enjoys established regulatory acceptance across global markets.

The material meets stringent standards including:

- ASTM F67: Standard specification for unalloyed titanium for surgical implant applications

- ISO 5832-2: Implants for surgery - Metallic materials - Part 2: Unalloyed titanium

- USP Class VI: Biological reactivity tests for medical plastics and metals

- FDA 510(k) predicate device recognition for established medical applications

Chuanghui Daye provides complete documentation packages including material test certificates, chemical analysis reports, and mechanical property verification. This documentation accelerates regulatory submissions and reduces approval timelines.

If you need materials with established regulatory pathways and comprehensive documentation support, then Grade 2 titanium wire from certified manufacturers provides essential compliance advantages.

Conclusion

Grade 2 titanium wire demonstrates clear advantages over alloyed alternatives in reducing implant rejection through superior biocompatibility. The material's pure composition, stable surface chemistry, and proven clinical performance make it the preferred choice for medical applications. Chuanghui Daye's advanced manufacturing processes and quality control systems ensure consistent material properties that medical device manufacturers require. When patient safety and long-term implant success remain paramount, Grade 2 titanium wire provides unmatched reliability and performance in critical biomedical applications.

Choose Chuanghui Daye as Your Trusted Grade 2 Titanium Wire Supplier

Chuanghui Daye combines three decades of titanium expertise with state-of-the-art manufacturing capabilities. Our ISO 9001:2015 certified facility produces medical-grade titanium wire meeting the most demanding biocompatibility requirements. Whether you need standard specifications or custom configurations, our technical team provides comprehensive support from material selection through final delivery. Ready to enhance your medical device performance with premium Grade 2 Titanium Wire? Contact us at info@chdymetal.com to discuss your specific requirements with our materials specialists.

References

1. Brunette, D.M., Tengvall, P., Textor, M., & Thomsen, P. (2012). "Titanium in Medicine: Material Science, Surface Science, Engineering, Biological Responses and Medical Applications." Springer-Verlag Berlin Heidelberg.

2. Geetha, M., Singh, A.K., Asokamani, R., & Gogia, A.K. (2009). "Ti based biomaterials, the ultimate choice for orthopaedic implants – A review." Progress in Materials Science, 54(3), 397-425.

3. Liu, X., Chu, P.K., & Ding, C. (2004). "Surface modification of titanium, titanium alloys, and related materials for biomedical applications." Materials Science and Engineering: R: Reports, 47(3-4), 49-121.

4. Niinomi, M. (2008). "Mechanical biocompatibilities of titanium alloys for biomedical applications." Journal of the Mechanical Behavior of Biomedical Materials, 1(1), 30-42.

5. Rack, H.J., & Qazi, J.I. (2006). "Titanium alloys for biomedical applications." Materials Science and Engineering: C, 26(8), 1269-1277.

6. Williams, D.F. (2008). "On the mechanisms of biocompatibility." Biomaterials, 29(20), 2941-2953.