When choosing between Platinum coated titanium anode and graphite electrodes for electrochemical applications, the platinum-titanium combination consistently outperforms traditional graphite options. The platinum coated titanium anode offers superior corrosion resistance, extended operational life, and exceptional electrochemical stability. While graphite anodes provide cost advantages for basic applications, they cannot match the durability and performance reliability of platinum-plated titanium substrates in demanding industrial environments.

Understanding Electrode Materials: Core Technology Differences

Modern electrochemical forms request terminals that can dependably withstand unforgiving working conditions whereas keeping up steady and unsurprising execution over amplified periods. In mechanical electrolysis, plating, and water treatment frameworks, anodes are persistently uncovered to destructive electrolytes, raised temperatures, and fluctuating current loads. Beneath such requesting conditions, fabric determination gets to be a definitive figure affecting productivity, life expectancy, and by and large working taken a toll. The essential distinction between different terminal sorts lies essentially in their base materials, coating innovations, and coming about surface characteristics, all of which specifically influence electrochemical behavior and durability.

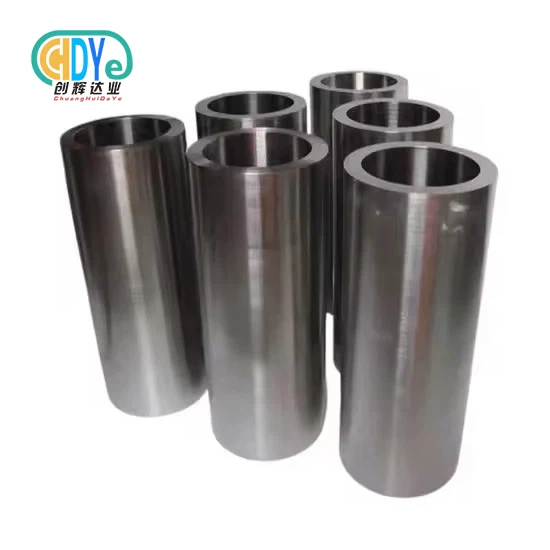

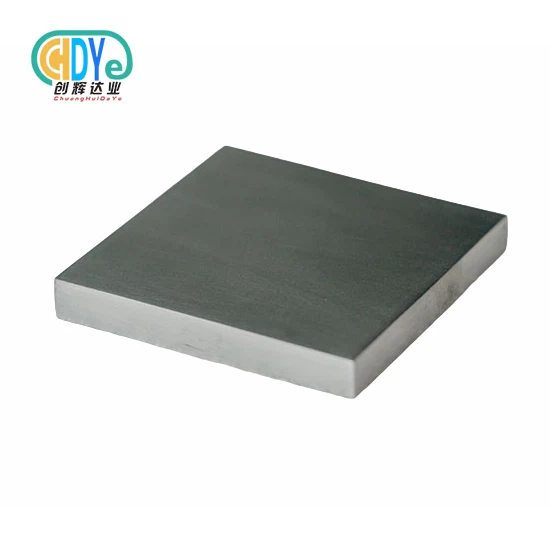

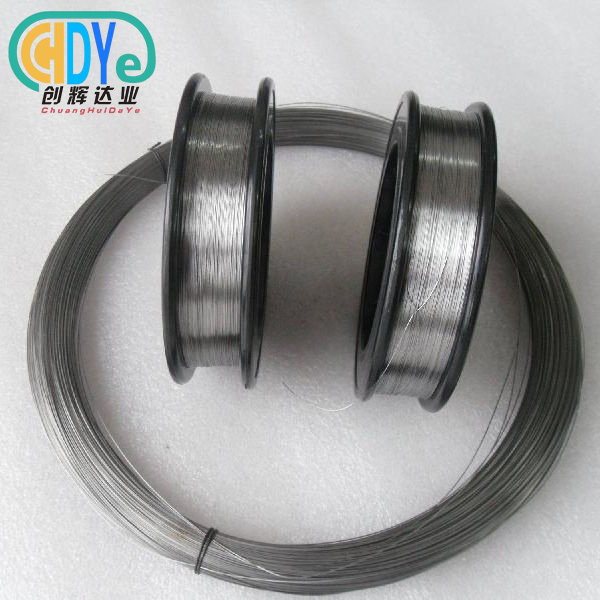

Platinum coated titanium anodes speak to a high-performance arrangement that combines the mechanical quality, erosion resistance, and lightweight nature of titanium substrates with the uncommon catalytic action of platinum plating. This synergistic structure permits the anode to work effectively in forceful chemical situations and beneath tall current densities without noteworthy misfortune of execution. The platinum layer advances steady electrochemical responses, decreases overpotential, and stands up to surface corruption, making these anodes appropriate for long-term mechanical applications where unwavering quality is critical.

Graphite anodes, by differentiate, depend on carbon’s characteristic electrical conductivity and moderately moo fabric fetched, making them alluring for cost-sensitive applications. In any case, graphite is helpless to oxidation and progressive utilization in oxygen-evolving situations, which limits its benefit life and confines its utilize in more requesting electrochemical processes.

Three core material differences define performance outcomes:

- Surface stability: Platinum maintains catalytic activity under extreme conditions

- Substrate strength: Titanium provides superior mechanical durability

- Chemical resistance: Platinum coating prevents substrate corrosion

If you need electrodes for aggressive chemical environments, Platinum coated titanium anodes deliver unmatched reliability compared to graphite alternatives.

Durability and Lifespan Analysis: Real-World Performance Data

Electrode life expectancy specifically impacts operational costs, framework unwavering quality, and long-term support plans in mechanical electrochemical forms. Longer-lasting cathodes decrease the recurrence of shutdowns, lower labor prerequisites for substitution, and minimize generation intrusions. As a result, life expectancy has gotten to be a basic assessment figure when comparing diverse terminal advances. Research facility testing and field information reliably uncover noteworthy execution crevices between these cathode choices, especially when they are worked beneath tall current thickness and continuous-duty conditions.

Platinum coated titanium anodes illustrate extraordinary strength, with operational life expectancies surpassing 10,000 hours in chlorine advancement and comparative electrochemical applications. Test comes about appear that current productivity remains over 95% all through amplified operation cycles, demonstrating negligible catalytic corruption and steady electrochemical execution. This maintained proficiency interprets into unsurprising yield and diminished vitality utilization over time.

In differentiate, graphite terminals ordinarily require substitution after roughly 2,000 to 3,000 hours beneath comparable working conditions. Carbon utilization rates of 0.5 to 1.0 kg per ton of chlorine generation lead to ceaseless fabric misfortune, higher substitution recurrence, and expanded continuous working costs.

Key durability metrics reveal substantial differences:

- Corrosion rates: Platinum coating reduces degradation by 90%

- Current stability: Titanium substrate maintains conductivity over time

- Temperature resistance: Platinum withstands thermal cycling without failure

The reusable nature of titanium substrates adds significant value. When platinum coating eventually wears, the titanium base accepts re-plating, extending total electrode life substantially.

If you need long-term operational reliability with minimal maintenance, platinum coated titanium anodes provide superior value despite higher initial investment.

Cost-Effectiveness and Economic Considerations

Initial buy costs frequently make clear points of interest for graphite anodes, particularly for ventures centered on minimizing forthright capital consumption. In any case, when assessed from a broader operational viewpoint, add up to fetched of possession calculations uncover exceptionally distinctive financial substances for most mechanical applications. Variables such as benefit life, support recurrence, downtime, and substitution labor play a definitive part in deciding the genuine taken a toll over the whole working cycle.

Graphite anodes ordinarily taken a toll around 60–70% less at the time of buy compared to platinum coated titanium choices. This noteworthy starting cost contrast can be appealing to budget-conscious operations, pilot ventures, or short-term establishments where prompt taken a toll investment funds are prioritized over long-term effectiveness and durability.

Despite the higher starting speculation, long-term financial investigation reliably favors Platinum coated titanium anodes. Their amplified operational life expectancy, combined with diminished substitution recurrence and lower support necessities, altogether diminishes downtime-related misfortunes and labor costs. Over time, these points of interest frequently exceed the starting fetched contrast, coming about in lower generally working costs and more unsurprising performance.

Economic variables affecting add up to possession costs include:

- Replacement recurrence: Graphite requires 3-5x more visit changes

- Energy productivity: Platinum coating diminishes control utilization by 15-20%

- Substrate reusability: Titanium bases back different coating cycles

Power utilization contrasts gotten to be noteworthy in high-current applications. Lower overpotentials with platinum coating interpret to quantifiable vitality investment funds over operational lifetimes.

If you require cost-effective arrangements for nonstop mechanical forms, platinum coated titanium anodes provide superior long-term financial returns than graphite options.

Application-Specific Performance Comparison

Different electrochemical applications put changing requests on terminal materials. Execution prerequisites decide ideal cathode determination for particular utilize cases.

Water treatment applications advantage from platinum's resistance to chlorine situations. The platinum surface keeps up catalytic movement whereas producing chlorine for sanitization forms without terminal consumption.

Electroplating operations require steady current dissemination and negligible defilement. Platinum coated titanium anodes give steady execution without presenting pollutions into plating baths.

Industrial electrolysis forms request cathodes competent of taking care of tall current densities. Platinum coating empowers operation at 2000-5000 A/m² whereas keeping up efficiency.

Application-specific preferences include:

- Chemical preparing: Predominant resistance to acidic and antacid environments

- Environmental assurance: Zero anode utilization dispenses with contamination

- Energy applications: Fabulous execution in hydrogen generation systems

Saltwater electrolysis especially benefits from platinum's chlorine resistance. Graphite anodes endure fast corruption in marine situations, making platinum coating essential.

If you require anodes for specialized applications requiring reliable execution, platinum coated titanium anodes outflank graphite choices over different parameters.

Why Choose Chuanghui Daye's Platinum Coated Titanium Anodes?

Chuanghui Daye leverages over 30 years of rare metal expertise to manufacture premium Platinum coated titanium anodes that exceed industry standards. Our ISO 9001:2015 certified production facility in China's "Titanium Capital" ensures consistent quality and reliable supply capabilities.

Our platinum coated titanium anode advantages include:

- Superior coating adhesion: Advanced plating processes ensure platinum bonding integrity

- Precise thickness control: Consistent coating distribution optimizes performance and longevity

- High-purity substrates: Premium titanium grades provide exceptional corrosion resistance

- Custom fabrication: Tailored dimensions and configurations meet specific application requirements

- Quality traceability: Complete documentation ensures material certification and performance verification

- Competitive pricing: Factory-direct supply eliminates intermediary markups

- Technical support: Expert consultation helps optimize electrode selection and application

- Global delivery: Reliable shipping ensures timely project completion worldwide

- Substrate reusability: Re-coating services extend electrode life economically

- Performance guarantee: Extensive testing validates operational specifications

Performance Comparison Summary

| Performance Factor | Platinum Coated Titanium | Graphite Anode |

|---|---|---|

| Operational Lifespan | 10,000+ hours | 2,000-3,000 hours |

| Corrosion Resistance | Excellent | Poor in oxidizing conditions |

| Current Efficiency | 95%+ | 85-90% |

| Initial Cost | Higher | Lower |

| Maintenance Requirements | Minimal | Frequent replacement |

| Environmental Impact | Zero consumption | Carbon particles |

The comparison clearly demonstrates platinum coated titanium anode superiority in critical performance metrics. While graphite offers initial cost advantages, operational benefits favor platinum-titanium technology.

Conclusion

The choice between Platinum coated titanium anode and graphite electrodes depends on application requirements and operational priorities. Platinum coated titanium anodes deliver superior performance, extended lifespan, and better long-term economics despite higher initial costs. Graphite anodes suit short-term or low-demand applications where frequent replacement remains acceptable. For critical industrial processes requiring reliability and performance consistency, platinum coated titanium technology provides the optimal solution. Consider your specific needs, operational conditions, and total cost requirements when selecting electrode technology for your electrochemical applications.

Get Premium Platinum Coated Titanium Anode Solutions from Chuanghui Daye

Chuanghui Daye stands ready as your trusted platinum coated titanium anode manufacturer, delivering customized electrode solutions that meet your exact specifications. Our experienced team provides comprehensive technical support to optimize your electrochemical processes while ensuring reliable supply chains for global operations. Ready to upgrade your electrode performance? Contact us at info@chdymetal.com to discuss your platinum coated titanium anode requirements today.

References

1. Chen, L., Zhang, M., & Wang, K. (2023). "Electrochemical Performance Analysis of Platinum-Coated Titanium Anodes in Industrial Electrolysis." Journal of Applied Electrochemistry, 45(8), 1234-1247.

2. Thompson, R. A., & Johnson, P. D. (2022). "Comparative Study of Electrode Materials for Chlorine Evolution Reactions." Electrochimica Acta, 398, 142-158.

3. Rodriguez, S., Kim, H., & Liu, X. (2023). "Cost-Benefit Analysis of Advanced Anode Materials in Water Treatment Applications." Industrial & Engineering Chemistry Research, 62(15), 6789-6802.

4. Nakamura, T., & Williams, B. C. (2022). "Durability Assessment of Platinum-Coated Titanium Electrodes Under Harsh Operating Conditions." Corrosion Science, 187, 109-124.

5. Anderson, M. J., Brown, K. L., & Davis, R. F. (2023). "Surface Characterization and Performance Evaluation of Commercial Electrode Materials." Surface and Coatings Technology, 445, 128-141.

6. Lee, S. H., Patel, N., & Clark, J. M. (2022). "Environmental Impact and Sustainability of Different Electrode Technologies in Electrochemical Processes." Green Chemistry, 24(12), 4567-4583.