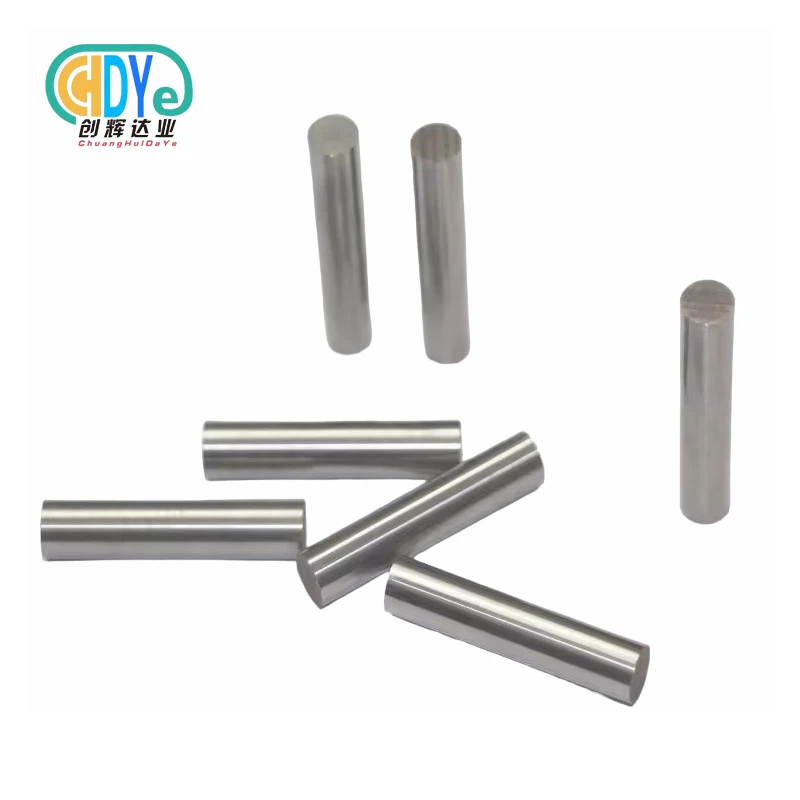

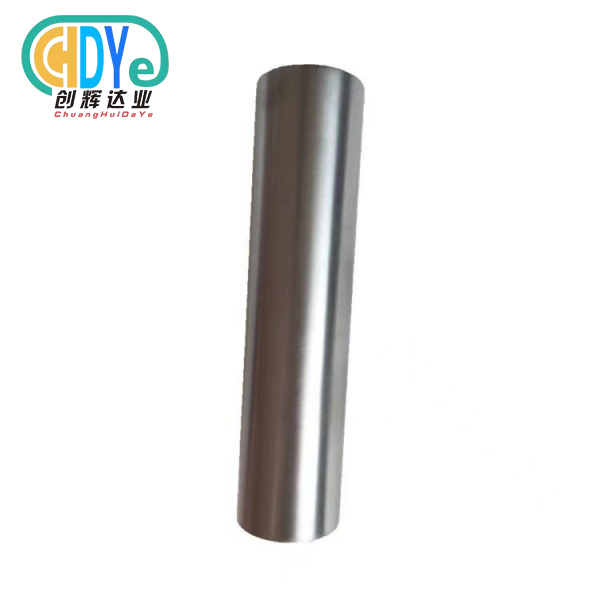

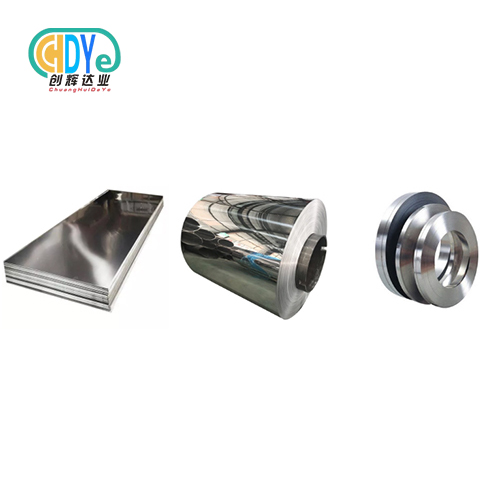

It takes a lot of work to find a trusted gr2 titanium pipe global export supplier because you need to look at their technical knowledge, quality certifications, and manufacturing capabilities. China is now one of the top countries making high-quality titanium products. Companies such as Shaanxi Chuanghui Daye Metal Material Co., Ltd. provide a wide range of titanium-based solutions for use in aerospace, medicine, chemical processing, and marine settings. The key is to find suppliers who have advanced manufacturing facilities, strict quality control systems, and a lot of experience with exports.

China's Titanium Manufacturing Excellence: Why Location Matters

Geographical benefits for strategy

China is an ideal manufacturing hub for titanium because of its unique geography and resources that benefit the industry. Baoji is a city in Shaanxi Province, which is called China's "Titanium Capital." There are many specialized manufacturers there with decades of experience making gr2 titanium pipe tubing. This focus builds a mature supply chain ecosystem that supports everything from processing raw materials to precision machining.

High-Tech Manufacturing Facilities

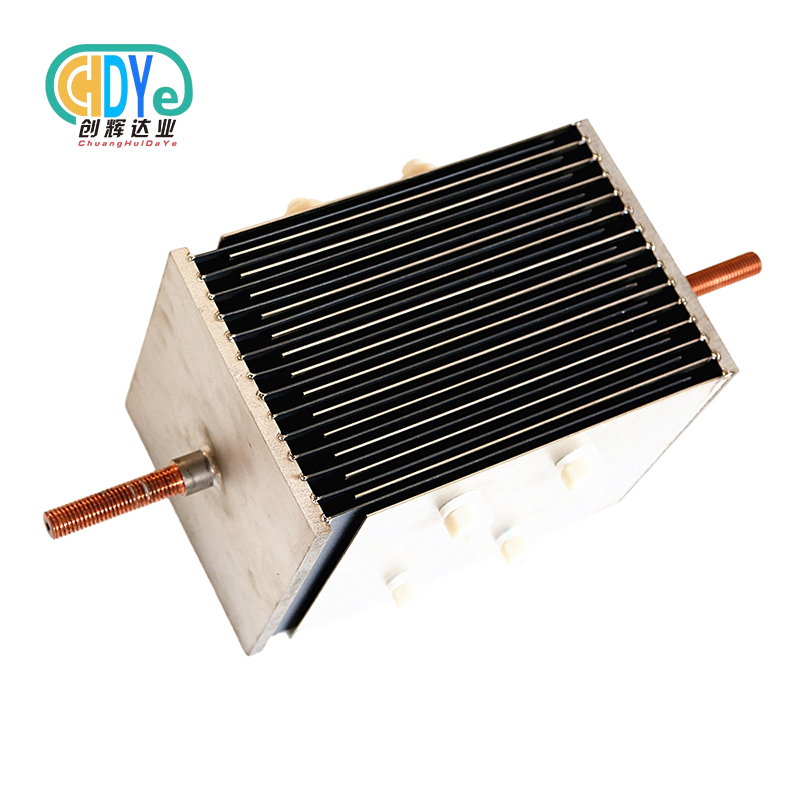

Chinese companies have spent a lot of money on cutting-edge machines for processing titanium. Electron beam melting furnaces, precision rolling mills, and cutting-edge heat treatment systems are all found in today's facilities. With these technologies, titanium alloy pipes with welded and seamless joints can be made all the time in a way that meets global standards. The infrastructure makes it possible to do both large-scale production and flexible small-batch manufacturing.

Affordable Production Options

China's manufacturing costs are still low because they maintain quality standards. This benefit comes from streamlined, cost-effective, and well-planned ways of making sure goods get to customers. Chinese suppliers are good options for long-term partnerships because buyers can get factory-direct prices without giving up on performance or reliability.

Essential Criteria for Evaluating Titanium Pipe Manufacturers

Test of Technical Knowledge

Trustworthy producers show that they know a lot about titanium pipe specifications and applications. They should give you in-depth technical papers that talk about the mechanical properties, chemical makeup, and dimensional tolerances. For both aerospace and corrosion-resistant titanium pipe systems or parts, find suppliers who can help with engineering and suggest the best ways to do things.

Assessment of Production Capacity

Check into the equipment details, production amounts, and delivery schedules that the company has the ability to make. Quality manufacturers keep enough space to make both standard products and custom titanium pipe fittings. They should be able to show that they can handle urgent projects without sacrificing quality on all orders, big and small.

Systems for Quality Control

Look at the manufacturer's quality management steps, from checking the raw materials to the last step of packaging. Chemical analysis, mechanical property verification, and dimensional inspection are all parts of the thorough testing that trustworthy suppliers do. They keep detailed records of traceability for each group of gr2 titanium pipes made in the factory.

Outstanding Customer Service

Professional manufacturers offer quick communication and technical support during the procurement process. Customers should be able to easily understand their prices, pay whenever they want, and know for sure when their packages will arrive. Find suppliers who know how to ship goods internationally and can quickly take care of the paperwork for exports.

The ability to do research and development

Continuous improvement and innovation are important to the top manufacturers. They are able to follow the changes in the industry and meet the needs of customers as those needs change. This includes making new ways to process titanium tubes, making the tubes bigger, and coming up with more solutions for specific problems.

Critical Certifications and Quality Standards

ISO methods for making sure quality stays high

ISO 9001:2015 certification means that quality management methods have been put in place for every part of the production process. This rule keeps things the same, makes progress, and keeps customers happy all the time. This certification means that the makers want to follow the rules and make the best products.

Following the Rules in Your Area

Making titanium pipes should follow global rules such as ASTM B861, ASTM B337, and ASME SB338. These standards include the tools and ways to test things, as well as information on how to judge whether something is okay. Compliance makes sure that the work follows both global engineering standards and rules.

Testing Materials and Certifying Them

For every shipment, mill test certificates should be requested. These certificates display the inspection results along with the chemical and mechanical properties. Honest manufacturers give you all the paperwork you need to test performance and trace the materials. This is very important for making medical-grade titanium pipe, aerospace, and other important things.

Effective Sourcing Strategies and Platforms

Direct Involvement of the Manufacturer

Build direct relationships with makers to get better prices, better communication, and better service. Dealing directly with the seller cuts out the markups that come from middlemen and gives you access to technical experts. Manufacturers in Baoji's titanium district, for example, help customers choose materials and do custom work.

Taking Part in Trade Shows

At trade shows, you can meet manufacturers in person and see what they can do. Big trade shows have new technologies and products, and give people a chance to network. These events make it possible to compare several suppliers side by side and judge how much they know about technology.

Professional Networks and Referrals

Use your contacts in the industry and professional networks to find good suppliers. Trusted partners' advice often helps manufacturers build good relationships. Industry groups and technical forums are good places to get information about how well suppliers are doing and how the market is changing.

Optimizing OEM and Custom Manufacturing Partnerships

The ability to work together on design

Choose manufacturers who can help make the product and give you advice on how to make the design better. Suppliers with a lot of experience know how titanium pipes are used in a variety of fields and can suggest ways to make performance, cost, or manufacturability. Working together like this helps make one-of-a-kind titanium pipes.

Services for Prototyping and Testing

Quality manufacturers can make prototypes quickly for custom applications. They should offer services for sample production, performance testing, and design validation. This makes it possible to do a full production run only after a full evaluation. This lowers the risks of the project and makes sure that the best results are achieved.

Intellectual Property Safety

Make clear agreements that protect private designs and other information. Intellectual property rights are important to honest businesses, and they keep information private during the development process. This kind of safety becomes very important when making new titanium pipes or specialized apps.

Strategic Approaches to MOQ and Pricing Negotiations

Getting to Know Market Pricing Changes

The price of titanium pipe depends on its grade, size, how much is ordered, and how it needs to be processed. Get quotes from a number of different suppliers so you can compare them and find out what's going on in the market. When you are looking at offers, think about the total cost of ownership, which includes shipping, handling, and possible duty charges.

Negotiation Strategies That Are Based on Volume

People who order more usually get better prices and better service. But, on the other hand, keep inventory and cash flow in mind when you make volume commitments. Some manufacturers allow flexible arrangements that let people place smaller orders at first, as long as they promise to order more over time.

Long-Term Partnership Advantages

Make strategic relationships that are good for everyone, including stable pricing, priority production scheduling, and better technical support. Long-term partnerships often lead to better business deals and more helpful service. Consistent customers are important to manufacturers, and many of them give trustworthy partners special attention.

Comprehensive Factory Audit and Quality Verification

Evaluation of the Manufacturing Facility

Do full inspections of the facility, looking at the state of the equipment, how maintenance is done, and what the production capabilities are. Check the manufacturing area for safety, organization, cleanliness, and good hygiene. Up-to-date buildings and well-cared-for tools show that a business is professionally run and cares about quality.

Review of Process Records

Look at the detailed process paperwork that goes over welding titanium pipes, heat treatment, and finishing. Quality manufacturers use thorough methods to make sure that all production runs have the same outcomes. Process parameters, inspection criteria, and corrective action procedures should all be part of the paperwork.

What the Quality Control Laboratory Can Do

Check the chemical analysis, mechanical property testing, and dimensional inspection tools that you have available for testing in-house. Modern labs with calibrated tools make sure that quality checking is done right. Manufacturers should show that they can do all of the tests that are required by titanium pipe standards.

Identifying Leading Suppliers in 2026: Key Performance Indicators

Leadership in New Technology

Top companies put money into new technologies and programs that help people do their jobs better all the time. They show that they can make complicated titanium pipe specifications and are able to meet changing customer needs. Innovation leadership includes coming up with new ways to do things and getting involved in new areas of use.

Experience in the global market

The best suppliers have a lot of experience with exports and know what the markets are like in other countries. They keep logistics networks running and are able to quickly meet the shipping needs of the whole world. Having worked in a variety of markets shows that you can be flexible and provide professional service.

History of Customer Satisfaction

Look at customer reviews, case studies, and relationships with long-term clients. Manufacturers that are successful keep a high customer retention rate and get good feedback about product quality, delivery performance, and technical support. This history shows that a trustworthy partnership could be in the cards.

Conclusion

A careful study of a Chinese gr2 titanium pipe manufacturer's technical skills, quality control, and ability to work with you is important for making the right choice. Finding suppliers with advanced manufacturing, proven quality management, and quick customer service is key to success. The time and money spent on a detailed supplier evaluation is worth it because it leads to trustworthy partnerships, consistent product quality, and good prices. For people all over the world who want high-quality titanium, Chinese companies, especially those in places like Baoji that are known for making titanium, offer very good reasons to buy from them. Focus on building long-term relationships with manufacturers who are dedicated to quality and continuous improvement.

FAQ

Q: What are the main differences between welded Grade 2 titanium pipes and those made without seams?

A: Titanium pipes without any weld seams are stronger than other pipes and better at not getting corroded. This means they're great for situations where a lot is at stake. For most industrial situations where pipes don't need to handle a lot of pressure, welded pipes are better and cheaper.

Q: How can I be sure that the pipes Chinese companies are making are made with good titanium?

A: Get mill test certificates, have a different company do the inspections, and make sure that global standards like ASTM B861 are met. A good business does quality checks and makes sure that people know a lot about their products.

Q: How many pipes is the least amount that Chinese companies that make pipes out of titanium can sell to me?

A: MOQs are not always the same for different products and makers. For normal sizes, they usually weigh between 100 kg and 1000 kg. If you want to make custom sizes, you may need to buy more than the bare minimum to make the money spent on tools and setup worth it.

Partner with Chuanghui Daye for Premium Titanium Solutions

In China, Shaanxi Chuanghui Daye is one of the top companies making GR2 titanium pipes. They have been making their products with advanced technology for more than 30 years. Our factory in Baoji is ISO 9001:2015 certified, which means that the titanium pipes we make for use in aerospace, medicine, and chemical processing are sure to be of high quality and meet global standards. We want to help your project succeed by offering a range of production options, competitive prices, and a lot of technical help. Do you want to get high-quality titanium materials? To get more information about prices and specifications, please send an email to info@chdymetal.com.

References

1. American Society for Testing and Materials. "Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers." ASTM B338-18, 2018.

2. Boyer, R., Welsch, G., and Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International, Materials Park, OH, 1994.

3. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International, 2000.

4. International Organization for Standardization. "Quality Management Systems - Requirements." ISO 9001:2015, 2015.

5. Lutjering, G. and Williams, J.C. "Titanium: Engineering Materials and Processes, 2nd Edition." Springer-Verlag Berlin Heidelberg, 2007.

6. Peters, M., Kumpfert, J., Ward, C.H., and Leyens, C. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, Vol. 5, No. 6, 2003.