- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Tantalum Tube and Pipe Manufacturing Methods Compared

When purchasing tantalum tubes and pipes for important industrial uses, it is very important for procurement workers to understand how they are made. There are many different ways to make tantalum today, from seamless extrusion to precise welding. Each has its own benefits when it comes to corrosion protection, mechanical properties, and cost-effectiveness. These differences in how the products are made have a direct effect on how well they work in harsh settings like chemical processing, aerospace systems, and semiconductor fabrication, where the reliability of the materials is key to operational success.

Understanding Tantalum Tubes and Pipes

The metal tantalum is one of the least reactive chemicals available on the market. It is very resistant to acids like hydrochloric acid, sulfuric acid, and aqua regia when heated. These tubes are very stable at high temperatures; their melting points are higher than 2996°C. This makes them essential for high-temperature uses where other materials fail.

Key Properties and Material Advantages

Tantalum materials are special because of the way their atoms are structured and how they are processed. In contrast to titanium or stainless steel, tantalum stays strong even when it is exposed to harsh chemicals that would quickly break down other materials. This better corrosion resistance comes from a stable oxide layer that fixes itself when it gets broken, making sure that it will work for a long time in important situations.

When products are made according to ASTM B521 guidelines, the quality and dimensions are always the same, no matter what the shape or size is. The material categories R05200 and R05400 are the most frequently specified options, with R05200 achieving electron-beam refined purity exceeding 99.95%, and R05400 utilizing powder metallurgy consolidation to improve workability.

Seamless vs. Welded Construction Differences

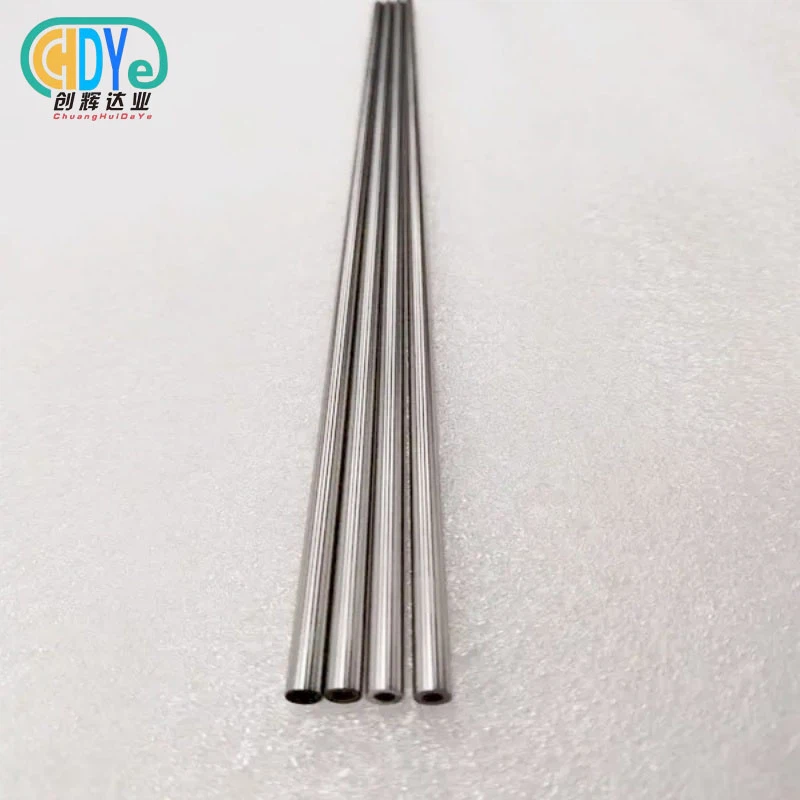

To choose the right material, it's important to know the basic differences between smooth and welded tantalum tubes. Solid billet extrusion is used to make seamless tubes, which makes the wall width continuous without any gaps between the joints. This method gets rid of any possible weak spots that come with welded gaps and gives better pressure ratings, usually above 7 MPa.

Precision fusion welding of tantalum strips or foils is used to make welded tantalum pipes, which can have bigger diameters and thinner wall sections than seamless pipes. Modern welding methods make joints that look almost like they are one piece, and they can save you money in certain diameter ranges and situations where you need non-standard measurements.

Manufacturing Methods of Tantalum Tubes and Pipes

Modern factories that make tantalum tubes and pipes use complex metallurgical methods to get the best qualities from the material while keeping the dimensions exact. Compared to older methods, these ones have changed a lot. They now use more advanced systems for controlling temperature, managing air quality, and making sure the quality of the products is good.

Traditional Manufacturing Approaches

In the past, rolling and drawing methods borrowed from other metal businesses were used a lot to process tantalum. These methods often led to uneven grain patterns and surface finishes that made them less useful for certain uses. Using old methods often had problems with work hardening, which meant that many annealing processes were needed, which took longer and cost more.

When compared to current techniques, older ways of making things usually had lower purity levels and more variations in size. Due to problems with quality control in older methods, material properties often changed a lot from one batch of production to the next. This caused supply chain risks for important uses.

Modern Advanced Manufacturing Processes

Today, electron beam furnace refining and precision forming methods are used together to make tantalum tubes with better material properties. The advanced manufacturing method starts with high-purity tantalum ingots that come from approved suppliers. This makes sure that the quality of the starting material is always the same.

Here are the core advantages of modern manufacturing approaches:

• Electron beam melting achieves ultra-high purity levels while creating uniform grain structures that enhance mechanical properties and corrosion resistance throughout the material cross-section

• Multi-stage cold drawing with intermediate annealing provides precise dimensional control while optimizing internal stress distribution for improved formability and service life

• Controlled atmosphere processing prevents contamination during critical manufacturing steps, maintaining material purity essential for semiconductor and medical applications

• Advanced surface treatment delivers exceptional surface finishes that reduce contamination risks and improve cleanability for sanitary applications

These manufacturing improvements directly address production challenges encountered in demanding industrial environments. Modern processes consistently deliver materials with predictable properties and enhanced reliability compared to traditional alternatives.

Quality Control and Certification Standards

Tough quality control methods make sure that every tantalum tube meets certain performance standards before it is sent out. ISO 9001:2015 approval sets the standards for complete quality control, which includes checking the raw materials, keeping an eye on the production process, and checking the finished product. Chemical analysis, review of mechanical properties, and verification of dimensions using high-precision measuring tools are all examples of advanced testing capabilities.

Evaluating Manufacturing Methods for Procurement Decisions

Before making a strategic procurement choice, all manufacturing methods must be carefully weighed against the needs of the application and the limitations of the operation. To get the best results for the project, the selection method involves finding the best balance between performance requirements, cost factors, and supplier capabilities.

Performance Criteria Assessment

Corrosion resistance, mechanical strength, and thermal stability needs are some of the most important performance factors. Seamless manufacturing usually has higher pressure rates and more even wall thickness distribution, which makes it better for high-pressure uses and important service conditions. Since there are no welded joints, there are no weak spots and the material features are the same all the way through the tube structure.

When it comes to big diameter applications and custom configurations, where seamless manufacturing is either too hard to do or too expensive, welded construction is better. With more advanced fusion welding methods, the joint properties get closer to those of the base material. This makes the joint reliable for many industry uses.

Cost and Supply Chain Considerations

By changing the prices of materials, wait times, and the amount of inventory needed, the choice of manufacturing method has a big effect on the total cost of the project. Because they are harder to make and are only made in small quantities, seamless tubes usually have higher prices. In long-term applications, though, their longer service life and lower maintenance needs often make up for the difference in starting cost.

When it comes to standard configurations and bigger quantities, welded alternatives usually offer lower costs. Because welded construction is so flexible in how it is made, it allows for quick customization and shorter wait times for non-standard dimensions, which helps project schedules with tight delivery requirements.

Global Sourcing and Supplier Evaluation

A good supplier evaluation looks at things like the seller's ability to make things, any quality certifications they have, and how reliable their supply chain is. The top companies that make tantalum keep state-of-the-art factories with electron beam ovens, precise machining tools, and full testing labs. Transportation logistics, regulatory compliance, and culture factors that affect communication and project management are all geographical factors that need to be thought about.

Being a certified supplier, such as having an ISO 9001:2015 quality management system, gives you peace of mind that the manufacturing method and product quality will be consistent. For complicated projects that need material optimization or custom specifications, technical support services like engineering consultation and application help are very useful.

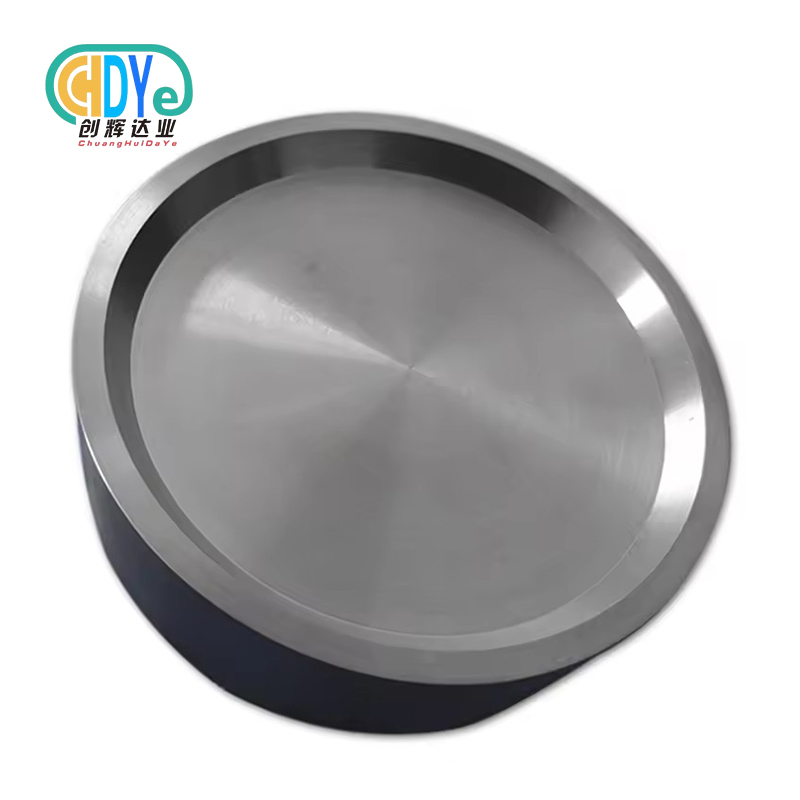

Chuanghui Daye: Advanced Tantalum Manufacturing Excellence

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is the leader in the business when it comes to making tantalum tubes and pipes. They have state-of-the-art production facilities and 30 years of experience working with rare metals. Our company is in Baoji, China, which is known as the "Titanium Capital." The city has great industrial infrastructure and well-established supply chains that help us get materials reliably and run our manufacturing processes efficiently.

Comprehensive Product Portfolio and Services

We can make both seamless and welded tantalum configurations, and our flexible production methods can meet the needs of a wide range of industries. You can get smooth tantalum tubes, welded tantalum pipes, precision capillary tubing, and heavy-wall configurations made to your exact measurements that meet ASTM B521 standards.

Through controlled manufacturing steps, the integrated production process makes sure that the material qualities are at their best. The first thing that is used to choose the raw materials is high-purity tantalum ingots that are more than 99.95% pure and can only be bought from certified sources who meet strict quality standards. Ultra-high purity is achieved through electron beam furnace refining, which also creates uniform grain structures that are necessary for consistent performance qualities.

For advanced manufacturing, hot forging and precision rolling are used to create a uniform microstructure. This is followed by multiple stages of cold drawing with intermediate annealing to get exact measurements. When heat treatment is done correctly, it relieves internal stresses while keeping the mechanical qualities that are wanted. Final machining, surface treatment, and end finishing make sure that the goods are exactly what the customer wants.

Quality Assurance and Technical Support

Our quality management system, which is ISO 9001:2015 certified, keeps a close eye on the whole production process, from inspecting the raw materials at the start to certifying the finished product. Before shipping, advanced testing tools can do a full chemical analysis, check the mechanical properties, and make sure the dimensions are correct.

As part of technical support services, engineers can get help choosing materials and make suggestions based on the application. Our expert team works with customers to make sure that the right materials are used in the right way, so that the system works well and doesn't cost too much. Rapid manufacturing helps with projects that need to be done quickly while still meeting quality standards that are important for important uses.

Conclusion

To choose the best way to make tantalum tubes and pipes, you have to carefully look at performance needs, cost limits, and the supplier's abilities. When it comes to important applications, seamless construction is best because it has higher pressure ratings and more consistent properties. On the other hand, welded alternatives are cheaper and can be made in a variety of configurations. When compared to older methods, modern ways of making things always result in better material properties and stability. Procurement choices that are good balance technical requirements with total cost, putting an emphasis on the expertise and quality assurance skills of the supplier to ensure the long-term success of the project.

FAQ

Q: What are the main differences between seamless and welded tantalum tubes?

A: Seamless tantalum tubes are manufactured through extrusion processes that create continuous wall thickness without joints, providing superior pressure ratings typically exceeding 7 MPa. Welded tubes utilize precision fusion welding of tantalum strips, enabling larger diameters and thinner walls while offering cost advantages for specific applications.

Q: How do manufacturing methods affect corrosion resistance properties?

A: Modern manufacturing methods using electron beam refining and controlled atmosphere processing maintain higher purity levels that directly enhance corrosion resistance. Seamless construction eliminates potential corrosion initiation sites associated with welded joints, while advanced welding techniques achieve joint properties approaching base material performance.

Q: What are typical lead times and minimum order quantities?

A: Lead times vary based on product specifications and manufacturing complexity, typically ranging from 4-8 weeks for standard configurations. Minimum order quantities depend on tube dimensions and customization requirements, with standard products available in smaller quantities while custom specifications may require larger minimum orders.

Partner with Chuanghui Daye for Superior Tantalum Solutions

Shaanxi Chuanghui Daye delivers exceptional tantalum tube and pipe solutions backed by three decades of rare metal expertise and ISO 9001:2015 certified manufacturing processes. Our advanced production facilities and comprehensive technical support ensure optimal material selection and reliable supply chain performance for your critical applications. Whether you require seamless tubes for high-pressure systems or welded configurations for specialized projects, our experienced team provides personalized consultation and competitive factory-direct pricing. Contact our tantalum tube and pipe manufacturer team at info@chdymetal.com to discuss your specific requirements and discover how our proven manufacturing excellence can enhance your project success.

References

1. ASM International Handbook Committee. "Properties and Selection of Refractory Metals and Alloys." ASM Handbook Volume 2: Properties and Selection of Nonferrous Alloys and Special-Purpose Materials. ASM International, 2018.

2. Cardonne, Steven M., et al. "Tantalum and Its Alloys: Manufacturing Processes and Industrial Applications." International Journal of Refractory Metals and Hard Materials, Vol. 73, 2019.

3. ASTM International. "Standard Specification for Tantalum and Tantalum Alloy Seamless and Welded Tubes." ASTM B521-98 (Reapproved 2015). ASTM International, 2015.

4. Miller, Gary L. "Tantalum Processing: Modern Manufacturing Techniques and Quality Control Methods." Journal of Materials Processing Technology, Vol. 284, 2020.

5. Thompson, Robert J. "Corrosion Resistance Evaluation of Tantalum Alloys in Chemical Processing Applications." Materials and Corrosion Engineering, Vol. 71, No. 8, 2020.

6. Zhang, Wei, et al. "Comparative Study of Seamless vs. Welded Tantalum Tube Performance in High-Temperature Industrial Applications." International Materials Reviews, Vol. 65, No. 4, 2021.

Learn about our latest products and discounts through SMS or email