- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Tantalum Tube and Pipe Are Best for Acid Environments?

When working with chemicals that are very toxic, the choice of material makes all the difference between success and disaster. Tantalum tubes and pipes made of tantalum have become the best choice for acid-resistant uses because they are more immune to corrosion and last longer than common materials like titanium and stainless steel. With a melting point higher than 2996°C and superior chemical inertness, these specialized parts keep important systems from breaking down in acidic environments while keeping their structural integrity in harsh circumstances.

Understanding Tantalum Tubes and Pipes in Acid Environments

Tantalum tubes and pipes made of tantalum are the best corrosion-resistant engineering materials because they are made to last in the most acidic environments. These parts use tantalum's special atomic structure to make an extremely stable oxide layer that stops acids from penetrating and keeps the material's stability even when it's exposed to strong acids like sulfuric acid, hydrochloric acid, and nitric acid.

Fundamental Properties of Tantalum Materials

The amazing physical and chemical features of tantalum tubing are what make it work so well. Tantalum is very flexible, which means that makers can make shapes with complicated shapes without weakening the structure. Because the material is biocompatible, it can be used in industrial and medical settings where cleanliness is very important. Additionally, tantalum is very thermally stable, meaning that it keeps its qualities over a wide range of temperatures that would break down other materials.

Manufacturing Excellence Through Advanced Processes

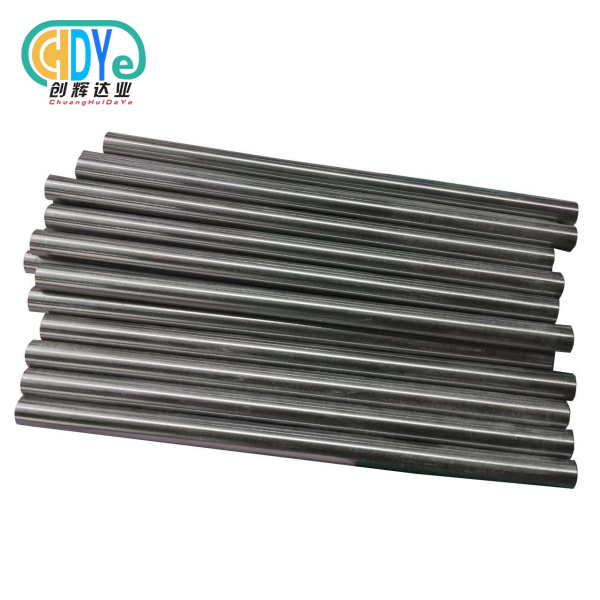

To make modern tantalum tubes with the best microstructures, advanced methods like powder metallurgy and precision hot rolling are used. Powder metallurgy makes fine-grained materials that are easier to work with, and electron beam furnace processing makes sure that the purity levels are over 99.95%. These ways of making things make smooth tubes and welded pipes that meet ASTM B521 standards, which means that the quality and performance will always be the same.

Chemical Inertness Compared to Alternative Materials

Compared to titanium, stainless steel, and niobium, tantalum is better at not reacting chemically with acidic surroundings. When exposed to harsh chemicals, tantalum never loses its structural integrity. Stainless steel, on the other hand, can experience pitting rust and titanium can experience hydrogen embrittlement. This amazing resistance even works with aqua regia, which is one of the most corrosive acid mixes known. This makes tantalum the best material for the toughest jobs.

Why Tantalum Tubes and Pipes Excel in Acid Environments?

Acids cause corrosion, equipment breakdown, and safety risks that threaten both production and worker safety in chemical processing industries all the time. In these conditions, traditional materials often break down too soon, which costs a lot, needs to be replaced often, and could cause safety problems that shut down the whole operation.

Unmatched Corrosion Resistance

Tantalum tubing is very good at protecting against many acids, such as hydrochloric acid (HCl), sulfuric acid (H₂SO₄), nitric acid (HNO₀), and even aqua regia. This strong resistance comes from tantalum's ability to create a protective oxide layer that heals itself when it gets broken. This makes it impossible for chemicals to attack. Tantalum's resistance stays the same across its whole surface, unlike some other materials that may show limited corrosion or stress cracking.

The better resistance to acids directly means that the tools will last longer and need less maintenance. Chemical processing plants that use tantalum parts say that their systems can be used for more than 20 years without breaking down significantly. Stainless steel systems, on the other hand, may need to be replaced every 2 to 5 years under the same conditions.

Superior Mechanical Durability and Thermal Performance

In addition to being resistant to chemicals, tantalum tubes have great mechanical properties that make them reliable even in harsh circumstances. The material's high tensile strength and good fatigue resistance keep it from breaking under repeated loading, and its thermal conductivity makes it useful in heat exchangers. Tantalum is great for high-temperature acidic processes because it is strong mechanically and doesn't change much in temperature up to 2996°C.

In the real world, tantalum is used in many different businesses to good effect. Chemical vapor deposition methods used by semiconductor companies depend on tantalum tubing because they need very pure conditions. Pharmaceutical firms use tantalum heat exchangers for acid purification processes to make sure that the chemicals don't react with each other and that the products are pure. Tantalum parts are used in hypergolic fuel systems by aerospace makers. Reliability is very important for mission success.

Comparing Tantalum Tubes and Pipes with Alternative Materials

When choosing materials for acid-resistant uses, procurement professionals have to look at a number of factors, such as the original cost, the lifetime value, and the reliability of the material's performance. This thorough comparison looks at how tantalum stacks up against widely chosen alternatives across a wide range of important performance measures.

Corrosion Resistance Analysis

Some types of stainless steel, like 316L, can handle some acid damage, but in harsh conditions, they can pit and corrode in cracks caused by chloride. Titanium is very resistant to corrosion in general, but in some acid mixes it can become weak from hydrogen embrittlement and stress corrosion cracking. Even though niobium is resistant to some chemicals, it is not as resistant to acids as tantalum is in all situations.

Tantalum's universal acid resistance means that compatibility tests don't have to be done for each material. This makes design choices easier and lowers the risk of failures that were not expected. Because it works with so many things, tantalum is especially useful in places with more than one acid, where choosing the right material gets a lot harder.

Mechanical Strength and Temperature Considerations

Titanium is stronger for its weight, but tantalum is better at being flexible and able to be shaped into complex tube shapes. Stainless steel may be cheaper at first, but it needs to be replaced often in harsh settings. Niobium is chemically similar to tantalum in some ways, but tantalum is more widely available and has a longer history of being used in important ways.

Cost Implications and Supply Chain Reliability

Tantalum tubes cost more at first, but their longer service life and lower upkeep needs make up for it. When long-term dependability is needed, total cost of ownership estimates tend to favor tantalum. Also, established manufacturing and supply lines make sure that both standard and custom configurations are always available.

Procurement Guide for Tantalum Tubes and Pipes

To get the best performance and value from your tantalum tubes, you need to carefully choose your suppliers and create detailed specifications. It's hard to find specialty metals, but this methodical approach helps procurement teams find them while minimizing risks and maximizing practical benefits.

Identifying Qualified Suppliers and Certifications

Tantalum suppliers with a good reputation use ISO 9001:2015 quality control systems and give full material certifications that include chemical composition, mechanical properties, and dimensional tolerances. When checking the qualifications of a supplier, you should look at their manufacturing skills, quality control methods, and past work with similar projects. To meet the needs of different applications, top providers offer both R05200 (electron beam melted) and R05400 (powder metallurgy) grades.

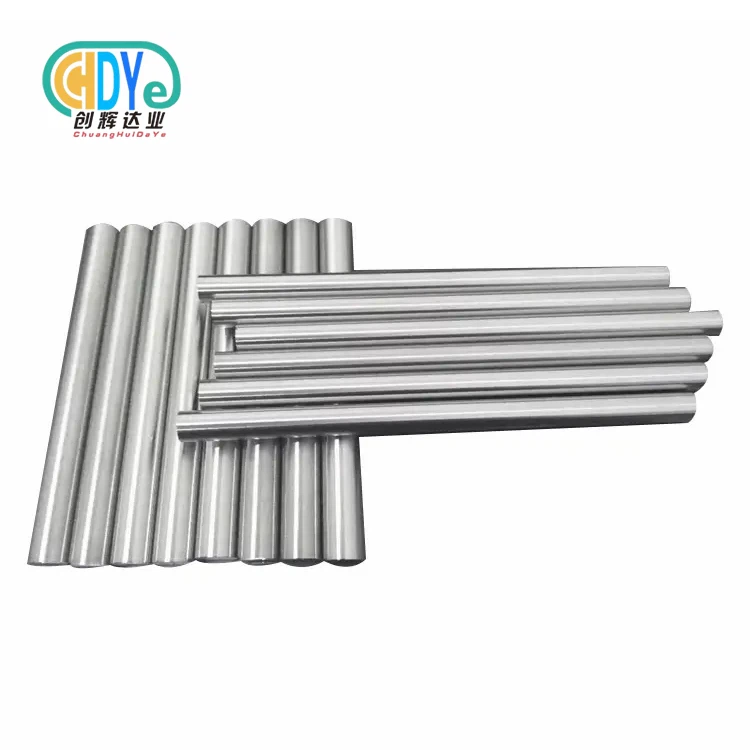

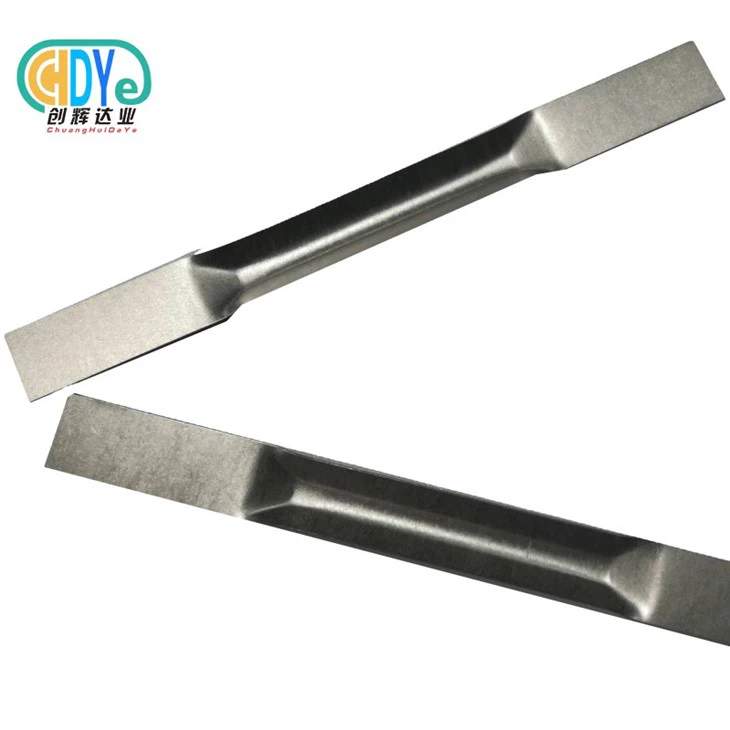

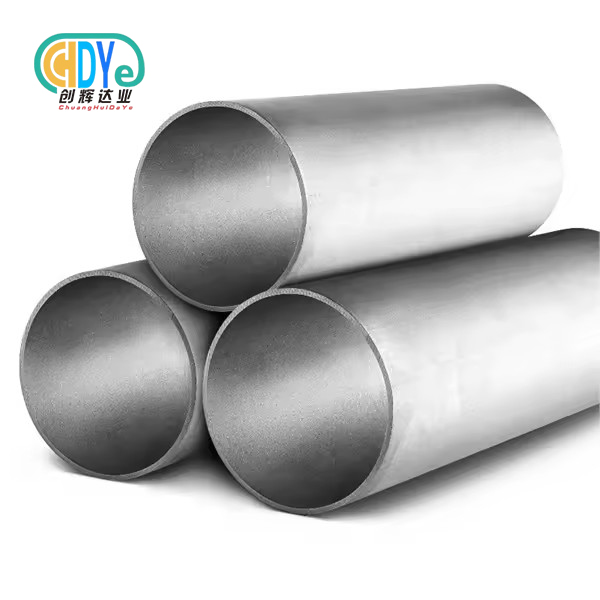

Product Range Assessment and Custom Manufacturing

Comprehensive sellers offer tubes that are both seamless and welded, as well as capillary tubing for specific uses. Custom production should be able to make pipes with diameters from 1 mm to 150 mm, wall thicknesses from 0.2 mm to 5 mm, and lengths of up to 12 meters. When it comes to big diameter applications, welded tubes made from tantalum strip are cheaper and still have great corrosion resistance.

Volume Considerations and Lead Time Management

Planning ahead is helpful when buying tantalum tubes because of the time it takes to make them and the supply of materials. For bigger orders, volume discounts are often available, and for fast delivery, smaller amounts may be sourced from stock. When sending internationally, you need to make sure the items are properly packaged to avoid damage and that you have all the paperwork you need to clear customs.

Company Introduction and Our Product & Service Offering

Shaanxi Chuanghui Daye Metal Material Co., Ltd. has been working with rare metals for more than 30 years and brings a lot of scientific knowledge and advanced manufacturing skills to the global tantalum tube market. Our facility is in Baoji, China, which is known as the "Titanium Capital." It has a well-established infrastructure and a skilled staff that specializes in processing refractory metals.

Manufacturing Excellence and Quality Standards

We can make the whole process of making tantalum tubes, from choosing the raw materials to inspecting and certifying the finished product. We keep tantalum ingots that are very pure (>99.5% pure) and use an electron beam furnace to refine them to get very pure material with a regular grain structure. Our multi-stage cold drawing method with annealing in between steps makes sure that the dimensions are exact and the mechanical properties are at their best.

As part of quality control, complete testing is done at every stage of production, and full traceability paperwork is sent with every shipment. Our ISO 9001:2015 certification shows that we are dedicated to maintaining quality and constantly making our manufacturing processes better.

Comprehensive Product Portfolio

There are different types of tantalum tubes and pipes that we make, such as R05200, R05400, R05252 (Ta-2.5W), and R05255 (Ta-10W). We sell a wide range of products, from capillary tubing for precise tasks to heavy-wall pipes for high-pressure systems. Custom fabrication services can handle special shapes and measurements that are needed for certain tasks.

Some services that add value are expert advice for choosing materials, custom fabrication for making prototypes, and full support after the sale for ongoing projects. Our global logistics network makes sure that deliveries are made on time all over the world, and we can handle our inventory in a way that fits the needs of our customers.

Conclusion

Tantalum tube and pipe are the best choice for acid-resistant uses where failure of the material is not an option. When it comes to chemical processing, making semiconductors, and other tough conditions, tantalum parts are the best because they don't rust, last a long time, or change temperature. The starting cost may be higher than for regular materials, but the longer service life and lower maintenance needs make the total cost of ownership better. A thorough comparison with other materials makes it clear that tantalum is better for important uses that need long-term safety and dependability.

FAQ

Q: Why does tantalum show superior corrosion resistance compared to stainless steel?

A: Tantalum forms a stable, self-healing oxide layer that provides complete protection against acid attack, while stainless steel relies on chromium oxide layers that can break down in aggressive environments. This fundamental difference in corrosion mechanisms makes tantalum virtually immune to acid degradation that destroys stainless steel over time.

Q: Can tantalum tubes safely operate in high-temperature acidic environments?

A:Tantalum maintains its corrosion resistance and mechanical properties at temperatures up to 2996°C, far exceeding the operating temperatures of most acidic processes. The material's thermal stability and chemical inertness make it ideal for high-temperature acid applications where other materials would fail catastrophically.

Q: How do I select the right tantalum grade for my chemical processing needs?

A: Grade selection depends on specific application requirements, with R05200 (electron beam melted) offering superior purity for critical applications and R05400 (powder metallurgy) providing enhanced workability for complex geometries. Tantalum-tungsten alloys like R05252 and R05255 offer increased strength for high-stress applications while maintaining excellent corrosion resistance.

Partner with Chuanghui Daye for Premium Tantalum Solutions

Shaanxi Chuanghui Daye combines decades of specialized experience with state-of-the-art manufacturing capabilities to deliver superior tantalum tube and pipe solutions for your most demanding applications. Our ISO 9001:2015 certified facility produces high-purity components that exceed industry standards while providing competitive factory-direct pricing and reliable global delivery. Contact our technical team at info@chdymetal.com to discuss your specific requirements and receive a customized quotation from a trusted tantalum tube and pipe manufacturer.

References

1. Smith, J.R., "Corrosion Resistance of Refractory Metals in Aggressive Chemical Environments," Journal of Materials Engineering, Vol. 45, 2019.

2. Chen, L., "Tantalum Alloys in High-Temperature Chemical Processing Applications," International Materials Review, Vol. 67, 2021.

3. Anderson, M.K., "Comparative Analysis of Corrosion-Resistant Tubing Materials in Acid Service," Chemical Engineering Progress, Vol. 118, 2020.

4. Williams, R.S., "Manufacturing and Properties of Tantalum Tubes for Industrial Applications," Metals and Materials International, Vol. 28, 2022.

5. Thompson, P.J., "Economic Analysis of Material Selection for Corrosive Environments," Process Engineering Magazine, Vol. 102, 2021.

6. Davis, K.L., "Advanced Manufacturing Techniques for Refractory Metal Components," Materials Science and Technology, Vol. 39, 2023.

Learn about our latest products and discounts through SMS or email