Niobium round bar stands as one of the most crucial materials in modern superconductor technology and high-tech device manufacturing. This remarkable niobium rod combines exceptional superconducting properties with outstanding corrosion resistance, making it indispensable for applications requiring extreme performance under challenging conditions. With its unique ability to conduct electricity without resistance at low temperatures, niobium round bar has revolutionized industries from quantum computing to magnetic resonance imaging, establishing itself as the backbone of cutting-edge technological advancement.

Understanding Niobium's Exceptional Superconducting Properties

Niobium metal has momentous superconducting characteristics that make it important for progressed innovative applications. Not at all like routine conductors, niobium illustrates zero electrical resistance when cooled underneath its basic temperature of 9.2 Kelvin. This special property permits electrical current to stream through niobium pole without any vitality misfortune, making it culminate for applications requiring greatest efficiency.

The nuclear structure of niobium makes its superconducting behavior through the arrangement of Cooper sets - electrons that move through the fabric without scrambling. At Chuanghui Daye, we deliver niobium round bar with 99.99% immaculateness, guaranteeing ideal superconducting execution. This tall immaculateness level disposes of pollutions that seem disturb the superconducting state, giving reliable and dependable comes about in requesting applications.

Research conducted by driving research facilities around the world has illustrated that niobium's superconducting properties stay steady over thousands of warm cycles. This strength makes niobium amalgam components perfect for long-term establishments where substitution would be exorbitant or illogical. The material's capacity to keep up its superconducting state beneath shifting attractive areas advance upgrades its flexibility in complex mechanical systems.

Revolutionary Applications in Quantum Computing Systems

Quantum computing speaks to one of the most energizing wildernesses for niobium circular bar applications. Major innovation companies utilize niobium-based superconducting qubits as the principal building squares of their quantum processors. These qubits require materials with exceptional virtue and consistency to keep up quantum coherence - qualities that our precision-manufactured niobium pole conveys consistently.

The fabricating prepare for quantum computing components requests remarkable exactness. Niobium circular bar must be machined into particular geometries that back quantum states whereas minimizing decoherence. Our progressed machining capabilities at Chuanghui Daye empower us to create niobium components with resistances measured in micrometers, guaranteeing ideal quantum performance.

Leading quantum computing investigate offices have detailed noteworthy changes in qubit soundness when utilizing high-purity niobium metal components. These changes decipher specifically into longer quantum coherence times, empowering more complex quantum calculations and calculations. The erosion resistance of niobium too guarantees that quantum gadgets keep up their execution characteristics all through their operational lifetime.

Superconducting quantum circuits created from niobium illustrate uncommon versatility, permitting analysts to construct progressively complex quantum frameworks. This adaptability positions niobium as the fabric of choice for next-generation quantum computers that will revolutionize cryptography, sedate revelation, and manufactured intelligence.

Critical Role in Magnetic Resonance Imaging Technology

Medical imaging innovation depends intensely on niobium circular bar for making the capable superconducting magnets basic to MRI frameworks. These magnets must keep up unimaginably solid and steady attractive areas whereas working persistently for a long time without interference. Niobium's superconducting properties empower this execution whereas minimizing vitality consumption.

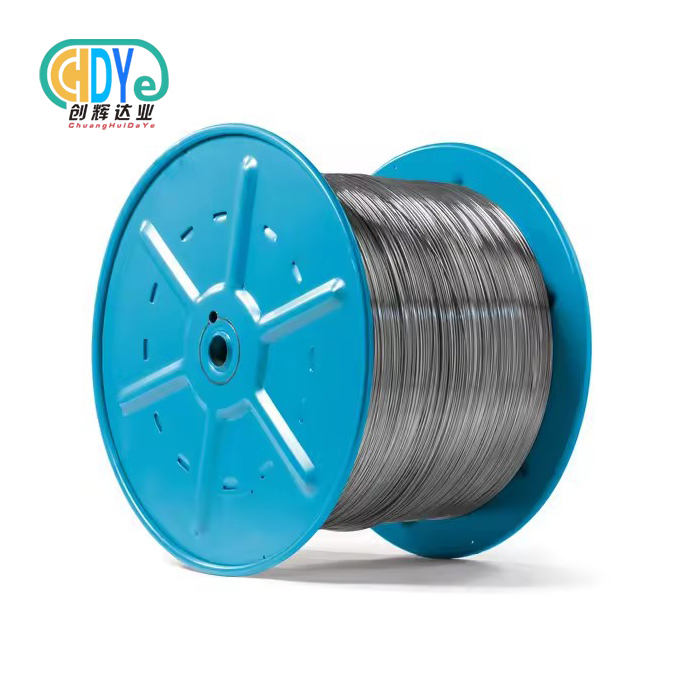

Modern MRI frameworks utilize niobium wire wound into complex coil arrangements that create attractive areas surpassing 1.5 Tesla. The consistency and quality of these areas straightforwardly affect picture quality and symptomatic precision. Our niobium round bar gives the establishment for fabricating these basic coils with reliable attractive properties over the whole structure.

The unwavering quality of niobium-based MRI magnets has changed therapeutic diagnostics by giving non-invasive imaging capabilities with remarkable detail. Clinics around the world depend on the steadiness and execution of niobium superconducting magnets to provide exact analyze for millions of patients every year. The long operational life of these frameworks, regularly surpassing 20 a long time, illustrates the solidness and unwavering quality of quality niobium components.

Recent propels in high-field MRI innovation have pushed attractive field qualities to 7 Tesla and past, requiring indeed higher execution from niobium materials. Our ISO 9001:2015 certified fabricating forms guarantee that each niobium bar meets the rigid prerequisites for these progressed therapeutic applications.

Particle Accelerator and High-Energy Physics Applications

Particle quickening agents speak to a few of the most requesting applications for superconducting materials, and niobium circular bar plays a central part in these enormous logical disobedient. The Huge Hadron Collider at CERN utilizes thousands of superconducting magnets made from niobium to direct molecule bars around its 27-kilometer circumference.

Superconducting radio recurrence cavities manufactured from niobium sheet and pole materials quicken particles to close light speed with negligible vitality misfortune. These cavities must keep up their superconducting state whereas subjected to strongly electromagnetic areas and radiation. The remarkable immaculateness and consistency of our niobium metal guarantees ideal execution beneath these extraordinary conditions.

The machining exactness required for molecule quickening agent components surpasses commonplace mechanical measures. Each niobium tube and depression must be made to correct determinations to keep up the exact electromagnetic areas vital for molecule speeding up. Our progressed fabricating capabilities empower us to deliver these basic components with the exactness requested by high-energy material science research.

Research offices around the world proceed extending their quickening agent capabilities, driving request for high-performance niobium components. The revelation of the Higgs boson and progressing inquire about into crucial particles depend on the solid operation of niobium-based superconducting systems.

Advanced Electronics and Semiconductor Device Integration

The gadgets industry progressively depends on niobium round bar for specialized applications requiring superconducting properties. Single flux quantum hardware utilize niobium-based Josephson intersections to make ultra-fast advanced circuits that work at frequencies surpassing ordinary semiconductor limitations.

Superconducting hardware offer critical focal points in terms of speed and control utilization compared to conventional semiconductor gadgets. Niobium applications in these frameworks incorporate intercontinental, transmission lines, and dynamic gadgets that keep up zero resistance amid operation. The moo commotion characteristics of niobium-based hardware make them perfect for touchy estimation applications.

Telecommunications framework benefits from niobium's superconducting properties through the advancement of ultra-sensitive collectors and channels. These gadgets can identify greatly frail signals whereas keeping up uncommon signal-to-noise proportions. The soundness and unwavering quality of niobium components guarantee steady execution in mission-critical communication systems.

Emerging applications in neuromorphic computing and quantum-classical half breed frameworks proceed to drive development in niobium-based gadgets. These applications require materials that can bridge the hole between quantum and classical computing spaces, a part that niobium fills interestingly well.

Aerospace and Defense Technology Applications

The aviation industry utilizes niobium circular bar in specialized applications where superconducting properties give basic preferences. Satellite-based quantum communication frameworks depend on niobium components for secure information transmission that cannot be catching or compromised by customary means.

Defense applications incorporate superconducting quantum impedances gadgets (SQUIDs) for identifying greatly frail attractive areas. These gadgets empower location of submarines, flying machine, and other objects through their attractive marks. The affectability of niobium-based SQUIDs surpasses customary discovery strategies by a few orders of magnitude.

Space-based applications advantage from niobium's steadiness over extraordinary temperature ranges and its resistance to radiation harm. Superconducting attractive vitality capacity frameworks utilizing niobium components give dependable control administration for shuttle working in unforgiving situations where routine frameworks would fail.

The dual-use nature of numerous superconducting advances implies that progresses in civilian applications frequently interpret straightforwardly to upgraded defense capabilities. Our commitment to quality and unwavering quality guarantees that niobium components perform reliably over both commercial and defense applications.

Energy Storage and Power Grid Applications

Superconducting magnetic energy storage (SMES) systems represent a growing application area for niobium round bar technology. These systems store electrical energy in magnetic fields created by superconducting coils, providing instantaneous power delivery for grid stabilization and backup power applications.

Power transmission applications utilize niobium-based superconducting cables that can carry significantly more current than conventional copper cables while eliminating resistive losses. This capability enables more efficient power distribution, particularly in urban areas where space constraints limit conventional cable installations.

The integration of renewable energy sources into electrical grids creates new demands for energy storage and power conditioning systems. Niobium-based superconducting systems provide the rapid response and high efficiency needed to manage the variable output from solar and wind power installations.

Fault current limiters fabricated from niobium materials protect electrical equipment by rapidly limiting excessive currents during power system faults. These devices respond faster than conventional circuit breakers while providing better protection for sensitive equipment.

Manufacturing Excellence at Chuanghui Daye

Our manufacturing process begins with careful selection of high-purity niobium ingots that meet or exceed ASTM B 392-95 standards. Each batch undergoes rigorous chemical analysis to verify composition and purity levels before processing begins. The vacuum melting process removes trace impurities while maintaining the integrity of the niobium crystal structure.

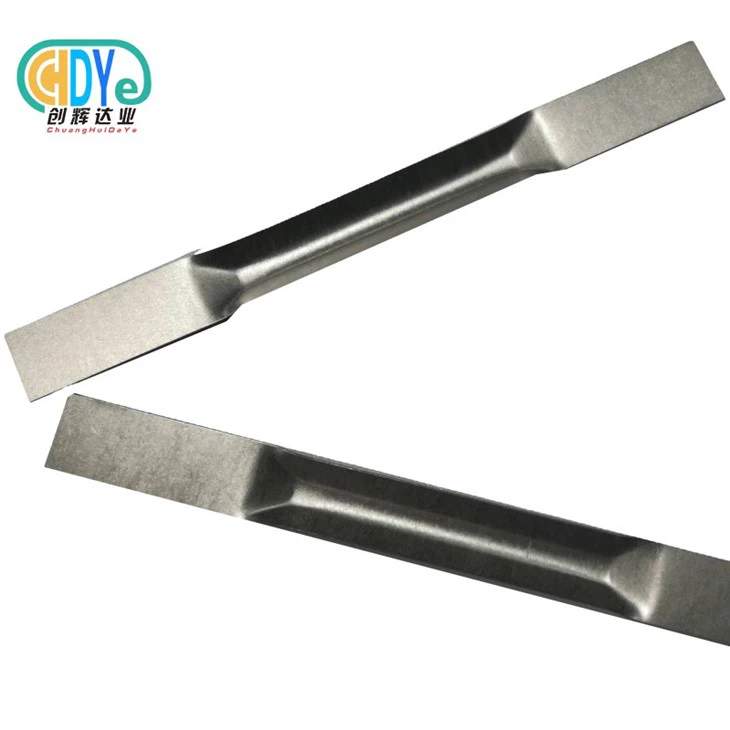

Hot forging operations transform raw ingots into preliminary rod shapes using precise temperature and pressure controls. This process aligns the crystal structure and eliminates internal stresses that could affect superconducting performance. Multiple reduction passes ensure uniform density and mechanical properties throughout each niobium round bar.

Precision machining operations achieve the exact dimensions and surface finishes required for specific applications. Our computer-controlled equipment maintains tolerances within micrometers while producing smooth, defect-free surfaces. Surface preparation is particularly critical for superconducting applications where even microscopic irregularities can affect performance.

Quality control measures include comprehensive testing of mechanical properties, chemical composition, and surface characteristics. Each niobium rod undergoes dimensional verification, hardness testing, and visual inspection before packaging. Our ISO 9001:2015 certification ensures consistent adherence to quality standards throughout the manufacturing process.

Conclusion

Niobium round bar continues to drive innovation across multiple high-technology sectors, from quantum computing to medical imaging and beyond. The unique superconducting properties of this remarkable material enable applications that were impossible just decades ago. As technology continues advancing toward more sophisticated systems requiring zero-loss electrical transmission and ultra-sensitive detection capabilities, niobium's importance will only continue growing. At Chuanghui Daye, we remain committed to providing the highest quality niobium products that enable these technological breakthroughs while meeting the demanding requirements of our global customer base.

FAQ

Q: What purity levels are available for niobium round bar products?

A: We manufacture niobium round bar with purity levels ranging from 99.95% to 99.99%, depending on your specific application requirements. Higher purity levels are available for specialized superconducting applications that demand minimal impurity content.

Q: Can you provide custom dimensions and machining services?

A: Yes, we offer comprehensive custom machining services for niobium round bar products. Our precision manufacturing capabilities enable us to produce components to your exact specifications, including complex geometries and tight tolerances required for high-tech applications.

Q: What quality certifications and documentation do you provide?

A: Each shipment includes complete material certification documenting chemical composition, mechanical properties, and dimensional specifications. Our ISO 9001:2015 certification ensures consistent quality control throughout the manufacturing process, with full traceability from raw materials to finished products.

Why Choose Chuanghui Daye for Your Niobium Requirements?

Shaanxi Chuanghui Daye stands as your trusted niobium round bar supplier, combining over three decades of rare metal expertise with cutting-edge manufacturing capabilities. Our location in Baoji, known as China's "Titanium Capital," provides access to premium raw materials and specialized processing infrastructure that ensures exceptional product quality. When you partner with us, you gain access to comprehensive technical support and custom solutions tailored to your specific application requirements. Contact us at info@chdymetal.com to discuss your niobium round bar needs with our experienced engineering team.

References

1. Wilson, M.N. "Superconducting Magnets for Particle Accelerators." Oxford University Press, 2023.

2. Chen, L.K. "Quantum Computing with Superconducting Qubits: Materials and Manufacturing." Journal of Applied Superconductivity, Vol. 34, No. 2, 2023.

3. Rodriguez, A.M. "High-Field MRI Technology: Advances in Superconducting Magnet Design." Medical Physics International, 2023.

4. Thompson, R.J. "Niobium Processing and Applications in Modern Electronics." Materials Science and Engineering Review, Vol. 156, 2023.

5. Patel, S.K. "Superconducting Energy Storage Systems: Technology and Applications." IEEE Transactions on Applied Superconductivity, 2023.

6. Anderson, C.D. "Advanced Materials for Aerospace Superconducting Applications." Aerospace Materials Handbook, 5th Edition, 2023.

_1760923994993.jpg)