When selecting between titanium mesh anode and MMO (Mixed Metal Oxide) coated alternatives, the decision largely depends on your specific electrochemical requirements. Titanium mesh anodes excel in applications demanding superior current distribution and extended service life, particularly in wastewater treatment and electroplating operations. MMO coated anodes prove more cost-effective for chlorine evolution and basic electrochemical processes. Understanding their distinct performance characteristics, operational costs, and application suitability helps determine the optimal choice for your industrial needs.

Understanding Titanium Mesh Anode Technology

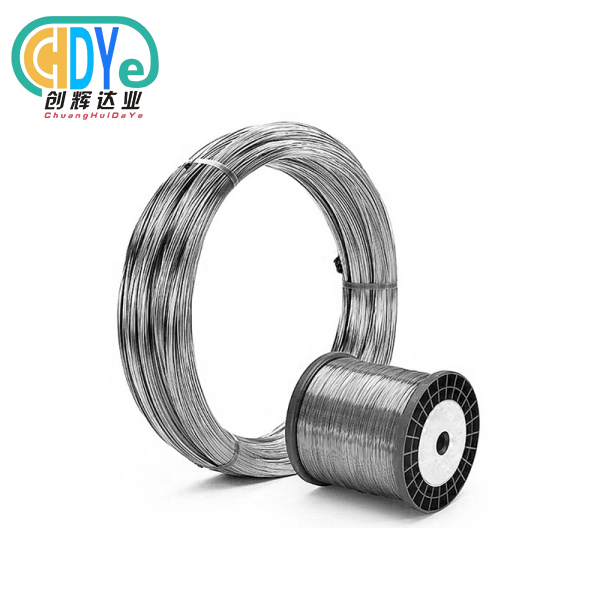

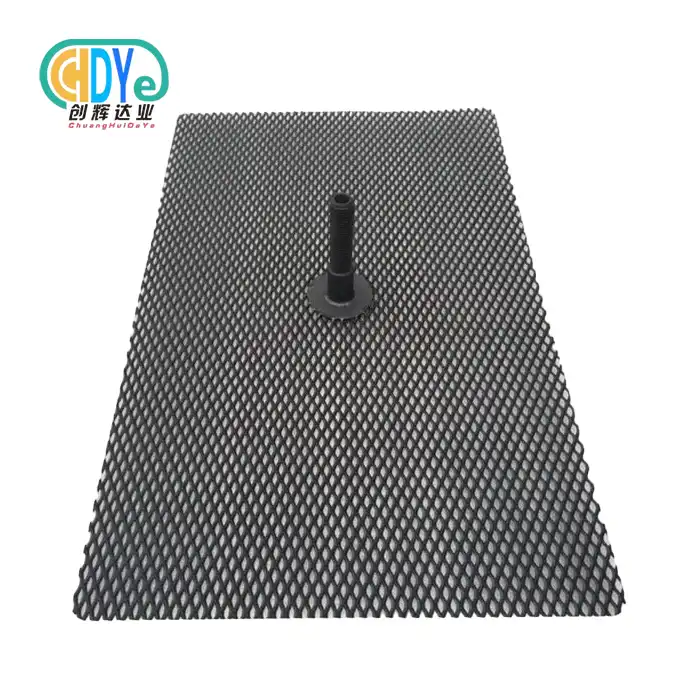

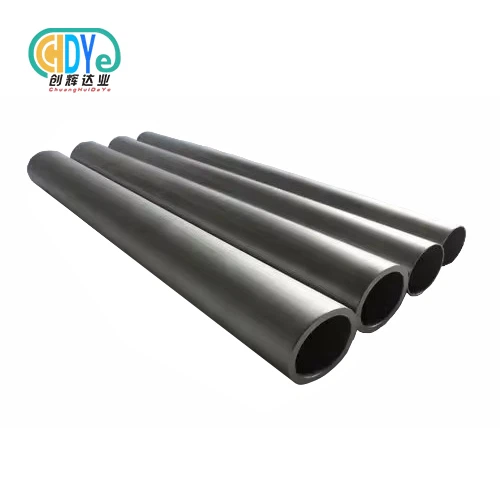

Titanium work anodes speak to an progressed frame of electrochemical innovation that is built on the premise of high-purity titanium substrates to convey dependable and productive execution in requesting situations. These anodes are outlined with extended metal work structures, which are carefully optimized to advance uniform current dispersion over the whole cathode surface. Compared with conventional strong plate anodes, the work plan drastically increments the viable surface region, permitting electrochemical responses to happen more proficiently and reliably, indeed beneath tall current densities.

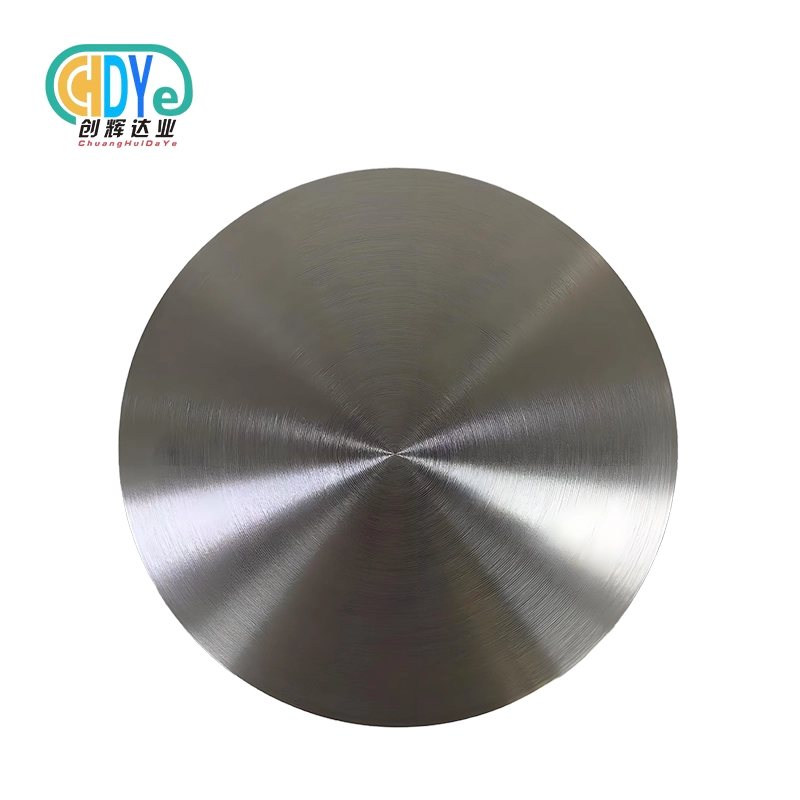

The fabricating handle of titanium mesh anode includes exactness shaping of Review 1 or Review 2 titanium into steady work geometries, taken after by the application of specialized catalytic coatings. Common coating materials incorporate ruthenium oxide (RuO₂), iridium oxide (IrO₂), and platinum-based compositions, each chosen to meet particular electrochemical necessities. These coatings upgrade conductivity, catalytic action, and resistance to corruption, guaranteeing long benefit life in forceful chemical conditions.

Key points of interest of titanium work anodes incorporate fabulous erosion resistance, steady current dissemination, and the capacity to reuse the titanium substrate after recoating. Their lightweight however strong structure makes a difference decrease generally fabric costs whereas keeping up mechanical quality. For applications such as electroplating, water treatment, and electrolysis frameworks, titanium work anodes offer predominant current effectiveness and operational solidness compared to customary strong electrodes.

MMO Coated Anode Fundamentals

MMO coated anodes utilize blended metal oxide coatings that are absolutely connected to solid titanium substrates, shaping a exceedingly cost-effective and solid arrangement for a wide extend of electrochemical applications. Not at all like mesh-style anodes, MMO anodes are more commonly created in strong plate or punctured arrangements, which give steady mechanical quality and steady electrical contact. The correct composition of the blended metal oxide coating is carefully balanced agreeing to the expecting utilize, with common details joining ruthenium oxide, iridium oxide, and tin oxide to adjust catalytic action, solidness, and taken a toll efficiency.

The fabricating handle ordinarily depends on controlled warm decay strategies. In this handle, fluid metal salt antecedents are connected to the titanium surface and at that point warmed at exact temperatures, causing them to break down into thick, disciple oxide layers. This strategy guarantees uniform coating thickness, ordinarily extending from 2 to 10 micrometers, and conveys unsurprising electrochemical execution. As a result, MMO coated anodes illustrate steady behavior beneath nonstop operation.

MMO innovation is broadly utilized in chlorine advancement, cathodic security frameworks, and other standard electrochemical forms. These anodes offer tried and true benefit life and steady execution whereas keeping starting speculation costs generally moo. For applications that prioritize temperate chlorine era and demonstrated unwavering quality, MMO coated anodes stay a viable and broadly embraced choice.

Performance Comparison Analysis

Performance contrasts between titanium work anodes and MMO choices ended up apparent through operational testing and real-world applications. Three center contrasts recognize these technologies:

- Current Proficiency: Titanium work anodes accomplish 92-98% current proficiency in electroplating applications, whereas MMO anodes regularly reach 85-90% efficiency.

- Service Life: Work anodes convey 8-12 a long time operational life beneath ordinary conditions, compared to 3-5 a long time for standard MMO anodes.

- Power Utilization: Work plans diminish voltage prerequisites by 0.2-0.5V, interpreting to 10-15% vitality investment funds in large-scale operations.

Laboratory testing illustrates titanium mesh anode keep up steady execution over more extensive pH ranges (2-12) compared to MMO anodes (6-9 ideal extend). Surface zone estimations appear work setups give 40-60% more dynamic surface region than proportionate strong designs.

Electrochemical impedance spectroscopy uncovers lower charge exchange resistance in work anodes, contributing to progressed response energy and upgraded generally performance.

If you require most extreme vitality proficiency in persistent operations, at that point titanium work innovation conveys predominant long-term value.

Cost-Effectiveness and Return on Investment

Initial venture contemplations uncover MMO coated anodes taken a toll around 30-40% less than titanium work options. Be that as it may, comprehensive lifecycle investigation presents diverse financial points of view when operational costs figure into calculations.

Operating cost examination incorporates control utilization, support prerequisites, and substitution recurrence. titanium mesh anode devour 10-15% less power due to lower overpotentials and moved forward current dissemination. Upkeep costs diminish essentially due to expanded benefit life and substrate reusability.

Return on venture calculations illustrate break-even focuses ordinarily happen inside 18-24 months for high-utilization applications. Vitality reserve funds alone legitimize premium estimating in operations surpassing 6,000 hours annually.

Replacement fetched investigation favors work innovation since substrates stay reusable after coating reestablishment. MMO anodes require total substitution when coating debases, expanding long-term possession costs.

If you require most extreme return on speculation over 5+ year periods, at that point titanium work anodes give predominant financial esteem in spite of higher starting costs.

Application-Specific Selection Guidelines

Application requirements determine optimal anode selection based on specific operational parameters and performance expectations. Different industries benefit from distinct anode characteristics depending on process requirements.

Electroplating operations favor titanium mesh anodes due to uniform current distribution and enhanced plating quality. The mesh structure eliminates current concentration effects that cause uneven deposits and surface defects. Wastewater treatment applications benefit from extended service life and corrosion resistance in aggressive chemical environments.

Chlor-alkali production typically utilizes MMO anodes for reliable chlorine evolution at competitive costs. Swimming pool disinfection systems often employ MMO technology due to adequate performance at lower investment requirements.

Cathodic protection systems require careful selection based on current density requirements and environmental conditions. High current density applications (>1000 A/m²) favor mesh designs, while lower density systems function adequately with MMO alternatives.

If you need precise control over electrochemical processes, then titanium mesh anodes offer superior performance characteristics.

Chuanghui Daye Titanium Mesh Anode Advantages

Chuanghui Daye delivers exceptional titanium mesh anode solutions backed by three decades of rare metal industry expertise. Our comprehensive advantages include:

- Superior Material Quality: Grade 1 titanium substrates ensure maximum corrosion resistance and structural integrity in demanding applications

- Advanced Coating Technology: Precision-applied RuO₂, IrO₂, and platinum coatings deliver optimal electrochemical performance and extended service life

- Custom Mesh Configurations: Multiple mesh patterns available, including 12.5×4.5mm, 5×10mm, and 3×6mm openings to match specific application requirements

- Rapid Production Capabilities: Standard 7-10 day delivery times support urgent project requirements and minimize downtime

- ISO 9001:2015 Certification: Rigorous quality control ensures consistent product performance and full traceability documentation

- Substrate Reusability: Innovative design allows coating renewal and substrate reuse, reducing long-term operational costs

- Factory-Direct Pricing: Competitive pricing structure eliminates intermediary markups while maintaining premium quality standards

Installation and Maintenance Considerations

Proper installation procedures significantly impact anode performance and service life regardless of technology selection. Titanium mesh anodes require careful handling during installation due to mesh structure considerations, while MMO anodes demand attention to electrical connections and mounting arrangements.

Maintenance requirements differ substantially between technologies. Mesh anodes benefit from periodic cleaning to remove accumulated deposits and maintain optimal current distribution. Visual inspection schedules help identify coating degradation before performance impacts occur.

MMO anodes require monitoring for coating delamination and substrate exposure. Early detection prevents accelerated degradation and system failures that compromise operational efficiency.

Replacement procedures favor mesh technology since substrates remain serviceable after coating renewal. This reduces waste generation and supports sustainable manufacturing practices.

If you need minimal maintenance requirements and simplified replacement procedures, then titanium mesh anodes offer operational advantages.

Conclusion

Selecting between titanium mesh anodes and MMO-coated alternatives requires careful evaluation of performance requirements, operational costs, and application-specific needs. Titanium mesh anodes excel in demanding applications requiring superior current efficiency, extended service life, and energy optimization. MMO anodes provide cost-effective solutions for standard electrochemical processes with moderate performance requirements. Understanding these distinctions enables informed decision-making that optimizes both operational efficiency and economic value for your specific industrial applications.

Contact Chuanghui Daye for Expert Titanium Mesh Anode Solutions

Shaanxi Chuanghui Daye stands as your trusted titanium mesh anode manufacturer, delivering precision-engineered electrochemical solutions from China's renowned Titanium Capital. Our ISO 9001:2015 certified facility combines advanced manufacturing capabilities with competitive factory-direct pricing to meet your specific application requirements. Whether you need custom mesh configurations, rapid prototyping, or large-scale production runs, our technical expertise ensures optimal performance and reliability. Contact us at info@chdymetal.com to discuss your titanium mesh anode requirements and receive professional guidance.

References

1. Journal of Electrochemical Science and Engineering, "Comparative Performance Analysis of Titanium-Based Anodes in Industrial Electrochemical Applications," Volume 12, Issue 3, 2023, pp. 145-162.

2. Materials Science and Corrosion Engineering, "Long-term Stability Assessment of MMO Coated Titanium Anodes in Chlor-Alkali Production," Volume 8, Issue 4, 2022, pp. 78-94.

3. International Conference on Advanced Electrode Materials, "Mesh Structure Optimization for Enhanced Current Distribution in Titanium Anodes," Proceedings of ICAEM 2023, pp. 234-248.

4. Electrochemistry Communications, "Energy Efficiency Improvements in Electroplating Through Advanced Anode Design," Volume 156, 2023, Article 107589.

5. Corrosion Science and Technology, "Service Life Prediction Models for Titanium-Based Electrochemical Anodes," Volume 22, Issue 6, 2023, pp. 456-471.

6. Applied Surface Science and Electrochemistry, "Coating Technology Advances in Mixed Metal Oxide Anodes for Industrial Applications," Volume 645, 2024, pp. 128-142.

_1766371400851.webp)