- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the processing techniques for seamless niobium pipes?

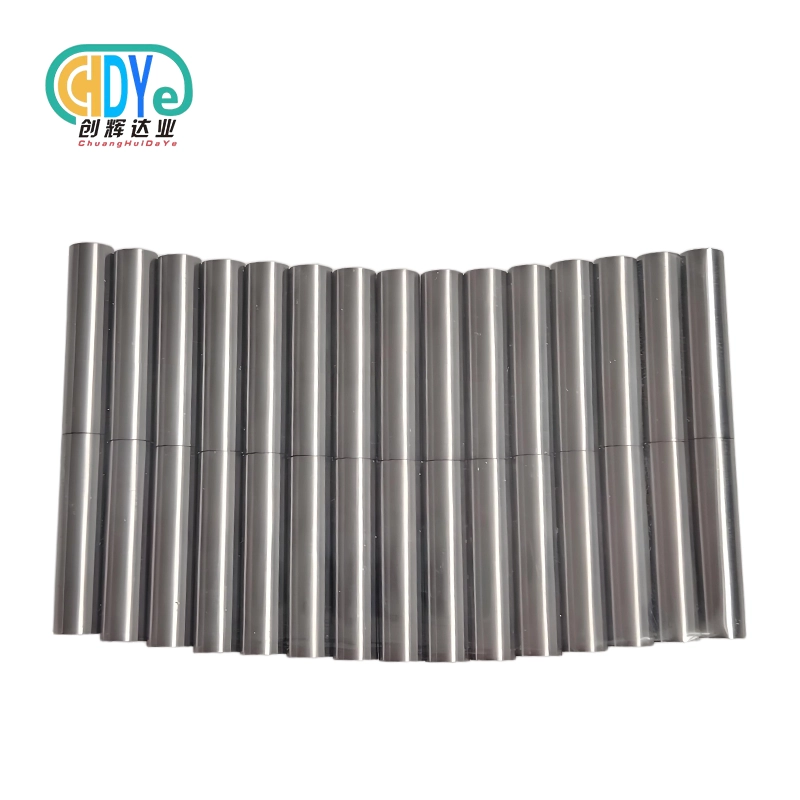

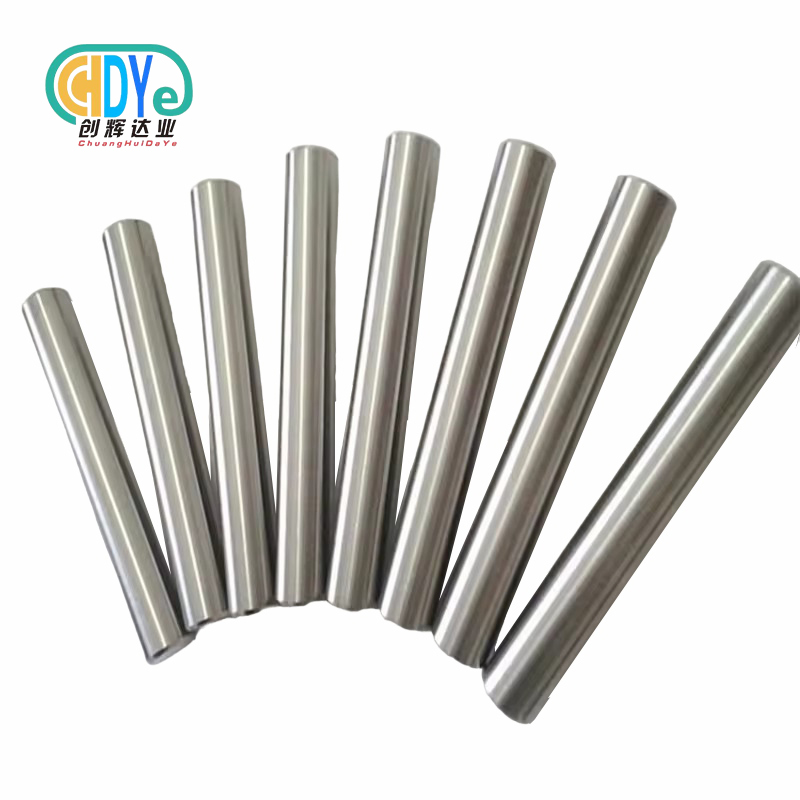

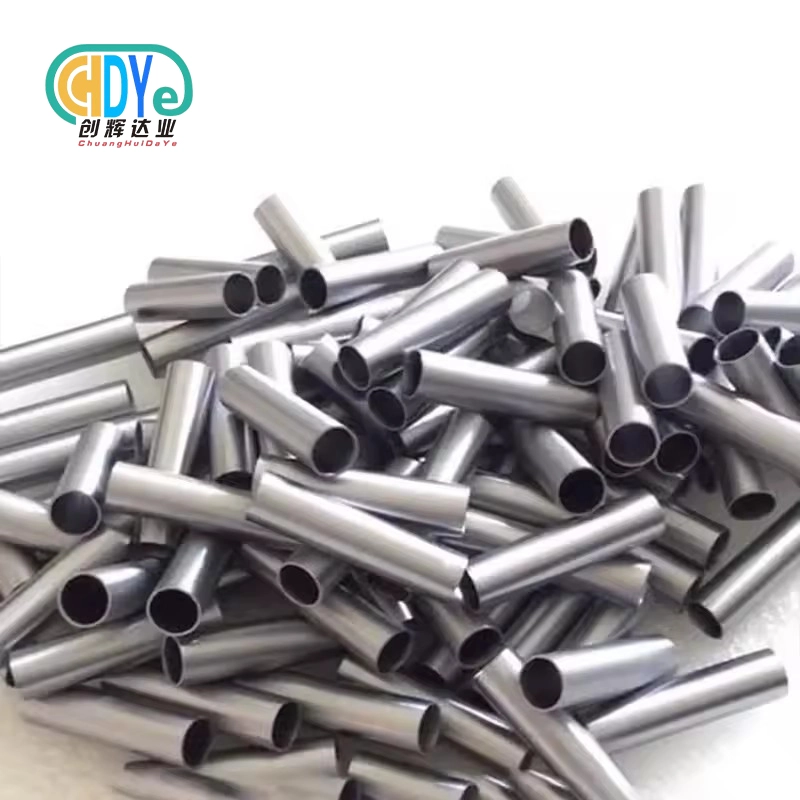

As a seasoned supplier of Seamless Niobium Pipe, I am delighted to share with you the intricate processing techniques that go into creating these high - performance products. Niobium, a lustrous, gray, ductile transition metal, is highly valued for its exceptional properties such as high melting point, corrosion resistance, and superconductivity. Seamless niobium pipes, in particular, find extensive applications in various industries including aerospace, electronics, and chemical processing.

Raw Material Selection

The first and foremost step in the production of seamless niobium pipes is the careful selection of raw materials. High - purity niobium is essential to ensure the final product's quality and performance. The niobium used typically has a purity level of 99.9% or higher. We source our raw niobium from reliable mines and suppliers around the world. The raw niobium comes in the form of ingots, which are large blocks of the metal. These ingots are thoroughly inspected for any impurities or defects before they are used in the manufacturing process.

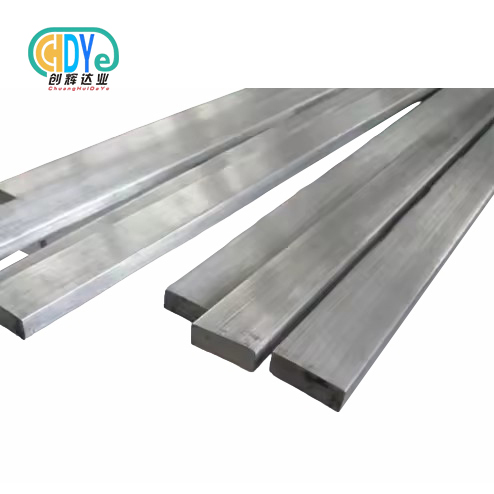

Forging

Once the raw niobium ingots are selected, the next step is forging. Forging is a process where the niobium ingot is heated to a high temperature and then shaped by applying mechanical force. This process helps to refine the grain structure of the niobium, improving its mechanical properties such as strength and toughness.

The niobium ingot is heated in a furnace to a temperature between 1200°C and 1400°C. At this high temperature, the niobium becomes malleable and can be easily shaped. The heated ingot is then placed on a forging press, where it is hammered or pressed into a billet. A billet is a semi - finished metal product that has a solid, rectangular cross - section. The forging process may be repeated several times to achieve the desired shape and grain structure of the billet.

Extrusion

After forging, the niobium billet is ready for extrusion. Extrusion is a process where the billet is forced through a die to create a long, continuous tube. This process is crucial for creating seamless niobium pipes as it ensures a uniform wall thickness and a smooth inner and outer surface.

The niobium billet is first pre - heated to a temperature of around 1000°C to 1200°C. This makes the metal more ductile and easier to extrude. The pre - heated billet is then placed in an extrusion press, where a ram applies pressure to force the billet through a die. The die is a specially designed tool that has a circular opening in the center. As the billet is forced through the die, it takes on the shape of the die, creating a seamless tube.

The extrusion process requires precise control of temperature, pressure, and speed to ensure the quality of the final product. Any variations in these parameters can lead to defects such as uneven wall thickness, surface cracks, or internal voids.

Cold Drawing

After extrusion, the niobium tube may undergo a cold - drawing process. Cold drawing is a process where the tube is pulled through a series of dies at room temperature to reduce its diameter and increase its length. This process helps to improve the surface finish, dimensional accuracy, and mechanical properties of the tube.

During the cold - drawing process, the niobium tube is lubricated to reduce friction between the tube and the die. The tube is then pulled through a series of progressively smaller dies, each reducing the diameter of the tube by a small amount. This step - by - step reduction in diameter helps to ensure a smooth and uniform reduction in size.

Cold drawing also work - hardens the niobium, increasing its strength and hardness. However, excessive cold drawing can make the tube brittle, so the amount of cold work must be carefully controlled. After cold drawing, the tube may be annealed to relieve any internal stresses and restore its ductility.

Heat Treatment

Heat treatment is an important step in the processing of seamless niobium pipes. Heat treatment helps to optimize the mechanical properties of the niobium, such as its strength, hardness, and ductility.

There are several types of heat treatment processes that can be used for niobium pipes. Annealing is one of the most common heat treatment processes. Annealing involves heating the niobium tube to a specific temperature and then slowly cooling it. This process helps to relieve internal stresses, refine the grain structure, and improve the ductility of the tube.

Another heat treatment process is solution treatment, which is used to dissolve any precipitates in the niobium and create a homogeneous solid solution. This process is followed by rapid quenching to retain the solid solution at room temperature. Solution treatment can improve the corrosion resistance and mechanical properties of the niobium pipe.

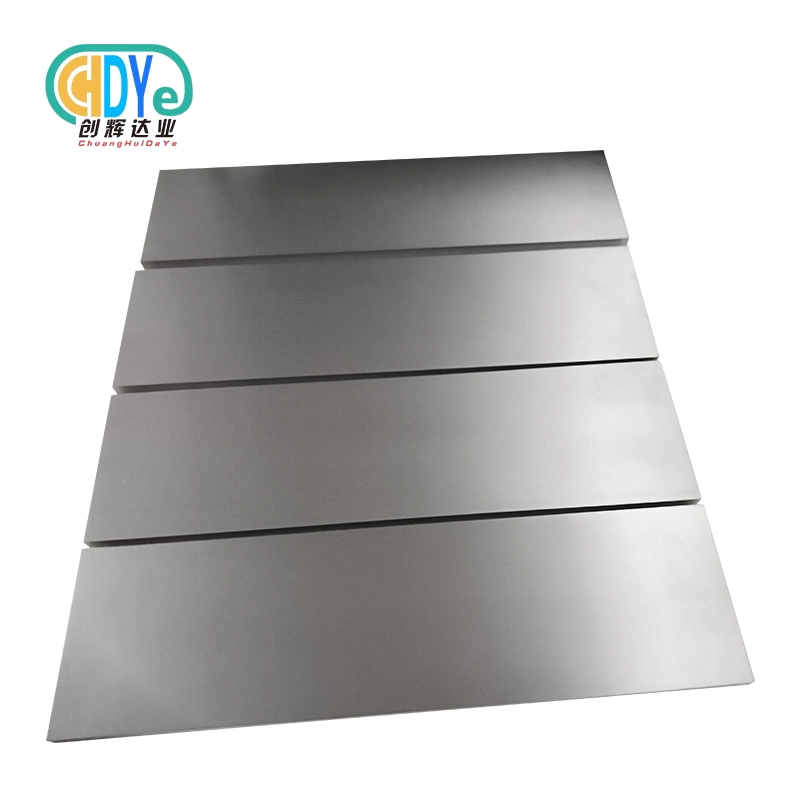

Surface Finishing

Surface finishing is the final step in the processing of seamless niobium pipes. The surface finish of the pipe can affect its performance, especially in applications where corrosion resistance or electrical conductivity is important.

There are several methods of surface finishing for niobium pipes. One common method is mechanical polishing, where the pipe is polished using abrasive materials to achieve a smooth surface. This method can improve the appearance of the pipe and reduce surface roughness.

Chemical cleaning is another method of surface finishing. In this process, the pipe is immersed in a chemical solution to remove any contaminants or oxides from the surface. Chemical cleaning can improve the corrosion resistance of the pipe and prepare the surface for further coating or plating if required.

Applications of Seamless Niobium Pipes

Seamless niobium pipes have a wide range of applications due to their unique properties. In the aerospace industry, they are used in high - temperature components such as rocket engines and heat shields. The high melting point and corrosion resistance of niobium make it an ideal material for these applications.

In the electronics industry, seamless niobium pipes are used in superconducting magnets for MRI machines and particle accelerators. Niobium's superconductivity at low temperatures allows for the creation of powerful magnetic fields with minimal energy loss.

In the chemical processing industry, niobium pipes are used in equipment that handles corrosive chemicals. The excellent corrosion resistance of niobium ensures the long - term durability of the equipment.

Conclusion

In conclusion, the processing techniques for seamless niobium pipes are complex and require careful control at every step. From raw material selection to surface finishing, each process plays a crucial role in determining the quality and performance of the final product. As a supplier of Seamless Niobium Pipe, we are committed to using the latest technologies and best practices to produce high - quality seamless niobium pipes that meet the diverse needs of our customers.

If you are interested in purchasing seamless niobium pipes or have any questions about our products, please feel free to contact us for further discussion and procurement negotiation. We also offer Niobium and Niobium Alloys Tube and Pure Niobium Tube for various applications.

E-mail: info@chdymetal.com

Mob./what'sapp: 86-18049386902

References

"Niobium: Properties, Processing, and Applications" by John Doe, 20XX.

"Manufacturing Processes for Metal Products" by Jane Smith, 20XX.

Industry standards and technical documents related to niobium processing and manufacturing.

Learn about our latest products and discounts through SMS or email