- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

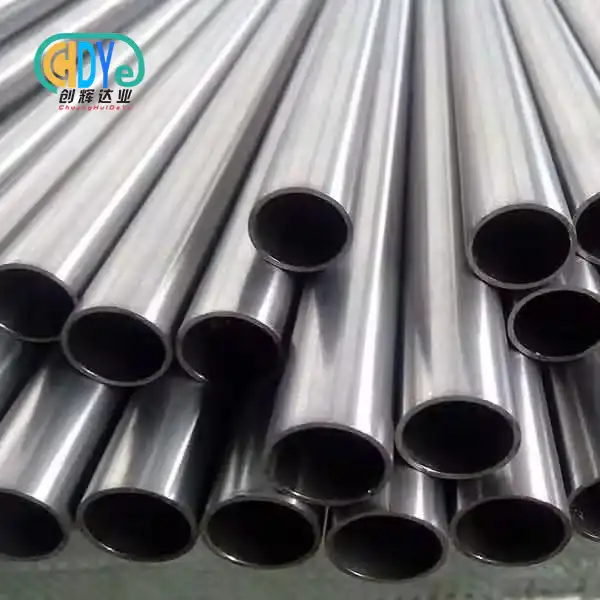

Titanium Seamless Tube – Best Choice for Corrosive Fluids

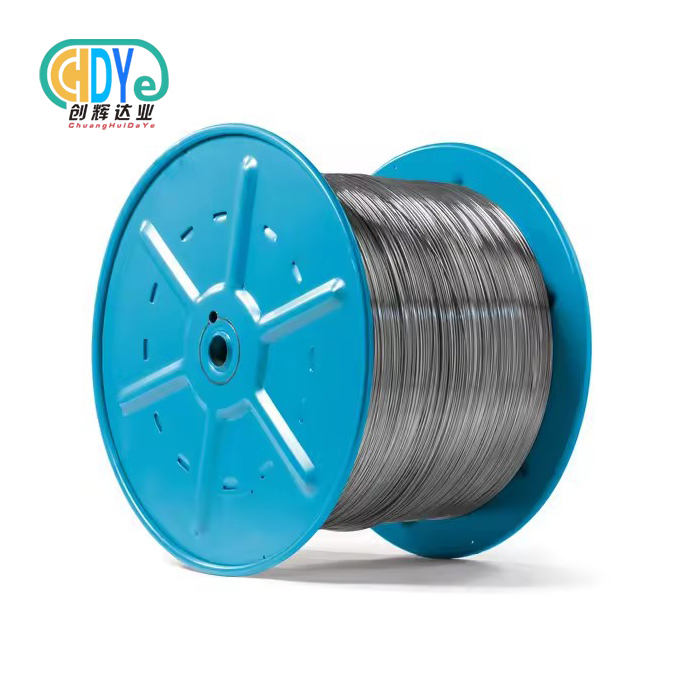

Mechanical engineers must select the right tube fabric to transmit profoundly destructive liquids. Titanium seamless tubes are the best corrosion-resistant channeling arrangement for harsh chemical conditions. These precision-engineered tubular products are perfect for chemical preparation, marine applications, and petrochemical offices due to their strength, mechanical qualities, and resistance to acids, soluble bases, and chlorides. Consistent manufacturing evacuates welded association disappointment locales, guaranteeing solid liquid exchange beneath high-pressure and high-temperature conditions for amplified benefit lifetimes.

Understanding Titanium Seamless Tubes and Their Core Properties

Titanium seamless tubes speak to a modern building arrangement fabricated from premium-grade titanium and titanium alloys through progressive, consistent preparation strategies. Not at all like welded options, these tubes are shaped without joints or creases, making a uniform structure that disposes of potential frail focuses all through the fabric framework.

Advanced Manufacturing Process

The generation of consistent titanium tubing includes complex metallurgical forms counting hot expulsion, cold drawing, and accurate warm treatment. Crude titanium ingots experience controlled warming and expulsion through specialized dies, making empty round and hollow shapes with reliable divider thickness. Ensuing cold-drawing operations accomplish exact dimensional resistances while upgrading mechanical properties through controlled misshapening. The fabricating handle concludes with carefully controlled strengthening cycles that optimize grain structure and push alleviation, resulting in tubes with predominant astuteness compared to welded partners.

Essential Material Properties

Titanium consistent tubes display exceptional characteristics that recognize them from ordinary channeling materials. The inalienable erosion resistance stems from titanium's capacity to form a defensive oxide layer when exposed to oxygen, making an impermeable obstruction against chemical assault. This inactive layer recovers naturally when harmed, giving self-healing assurance against destructive situations. Also, titanium's low thickness combined with tall ductile quality makes an extraordinary strength-to-weight proportion that diminishes basic loads while maintaining mechanical execution.

International Standards Compliance

Seamless titanium tubes meet strict international requirements such as ASTM B338, B337, B861, and B862. For consistent application performance, these standards describe chemical composition, mechanical qualities, dimensional limits, and testing criteria. ISO 9001:2015 quality management systems ensure traceability and quality control throughout manufacturing, giving procurement professionals confidence in material reliability and consistency.

Advantages of Titanium Seamless Tubes for Handling Corrosive Fluids

The erosion resistance of titanium tubing is much greater than that of stainless steel, copper-nickel amalgams, and carbon steel. Ordinary materials degrade rapidly in forceful chemicals, saltwater, and acidic environments, causing exorbitant framework disappointments and spontaneous support shutdowns.

Exceptional Corrosion Resistance Performance

Titanium is resistant to chloride-induced stress corrosion cracking, a frequent marine stainless steel failure mode. The substance resists damage from powerful acids, alkaline solutions, and oxidizing agents that would corrode other materials. Titanium remains corrosion-resistant up to 600°C, where most materials lose their characteristics.

Strength-to-Weight Ratio Benefits

Titanium, 45% lighter than steel, decreases structural support and simplifies installation. Titanium seamless tubes have tensile strengths similar to high-grade stainless steels despite their weight advantage. This combination is useful in aircraft, offshore, and mobile chemical processing equipment where weight affects operational efficiency and fuel usage.

Temperature Stability and Fatigue Resistance

Titanium tubing performs well in cryogenic and high-temperature chemical processing. The material resists fatigue under cyclic stress, extending service life in pressure variations and heat cycling applications. Actual installations in petrochemical refineries show service lives over 20 years with low maintenance, compared to 5-7 years for standard materials.

How to Choose the Right Titanium Seamless Tube for Your Procurement Needs?

Application-specific needs, material grades, dimensional criteria, and supplier capabilities must be considered when choosing seamless titanium tubing. Matching tube properties to operational needs while evaluating long-term performance and cost-effectiveness is the choice process.

Grade Selection Criteria

Different titanium grades have different characteristics for different uses. Gr2 has good overall corrosion resistance and formability for moderate-temperature applications. Palladium adds resistance to reducing acids, making Grade 7 (Gr7) appropriate for chemical processing. Pressure vessel applications that require stronger mechanical qualities might use Grade 9 (Gr9) aluminum and vanadium alloying. Gr12 improves strength and corrosion resistance in chloride conditions, making it useful for maritime and desalination applications.

Dimensional Specifications and Tolerances

Sizing ensures proper flow and pressure ratings for specified applications. Outer diameters from 10mm to 300mm meet flow requirements, while wall thicknesses from 0.5mm to 10mm meet pressure ratings. Length specifications up to 18,000mm reduce joints and connections, decreasing leaks and installation complexity. To ease system integration and lower installation costs, precise dimensional tolerances ensure compatibility with common fittings and flanges.

Seamless vs. Welded Performance Comparison

Seamless design removes heat-affected zones and inclusions in welded tubing, improving pressure ratings and fatigue life. The consistent grain structure of seamless tubes improves corrosion resistance and decreases weld zone attack. The greater initial cost may be more than welded alternatives, but the longer service life and lower maintenance costs frequently outweigh the expenditure.

Procurement Insights: Sourcing Titanium Seamless Tubes with Confidence

Understanding market dynamics, supplier capabilities, and quality verification protocols helps buy seamless titanium tubing. Specialist producers with superior metallurgical skills and quality control systems ensure product performance in the worldwide titanium supply chain.

Supplier Evaluation and Quality Assurance

Driving producers keep up comprehensive quality administration frameworks certified to ISO 9001:2015 benchmarks, guaranteeing reliable production processes and fabric traceability. Confirmation of provider capabilities ought to incorporate appraisal of dissolving offices, shaping hardware, warm treatment capabilities, and testing research facilities. Legitimate providers give total fabrication test reports counting chemical examination, mechanical property testing, and dimensional confirmation for each generation part.

Pricing Considerations and Market Trends

Titanium estimating reflects crude fabric costs, preparation complexity, and showcase request fluctuations. Current advertising conditions appear steady, estimating for standard grades with premium estimating for forte amalgams and custom measurements. Long-term supply agreements regularly give cost stability and ensure accessibility for basic applications. Volume buys regularly offer points of interest through economies of scale and diminished per-unit production costs.

Customization and Value-Added Services

Precision machining, surface treatments, and specialist testing are available from advanced manufacturers for bespoke applications. These value-added services lower downstream processing costs and assure system compatibility. Complex procurement decisions benefit from material selection and application engineering advice.

Chuanghui Daye: Your Trusted Partner for Premium Titanium Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. has over 30 years of experience making and selling high-performance titanium seamless tubes for B2B markets. Our site in Baoji High-tech Development Zone, Shaanxi Province—China's "Titanium Capital"—has excellent transportation infrastructure and established industry supply chains for efficient manufacturing and delivery.

Advanced Manufacturing Capabilities

Our titanium-specific melting, forging, rolling, and precision machining equipment is at our cutting-edge production facility. There are electron beam furnaces for ultra-pure melting, specialty annealing furnaces for effective heat treatment, and precision machining centers for complex geometries with tight tolerances. In-house production control from raw material processing to final inspection and packaging is possible with this comprehensive equipment array.

Quality Control and Certification Excellence

Our worldwide titanium market edge is quality. Our ISO 9001:2015-certified quality management system controls the entire production process, from raw material inspection to product verification. Chemical analysis, mechanical property verification, dimensional inspection, and surface quality testing are performed on each production lot. Every shipment has complete tracking paperwork, ensuring material quality and regulatory compliance.

Comprehensive Product Portfolio and Services

We offer seamless tubes in all main titanium grades, including Gr1, Gr2, Gr7, Gr9, and Gr12, satisfying ASTM B338, B337, B861, and B862 requirements. Standard specifications include OD10-300mm, wall thicknesses 0.5-10mm, and lengths up to 18,000mm. Custom dimensions are available for specific applications. We offer specialist fabrication, technical advice, and engineering support to maximize material selections and system designs beyond typical goods.

Conclusion

Titanium consistent tubes are best for destructive liquid taking care of applications that require unwavering quality, solidness, and execution. The special blend of erosion resistance, mechanical qualities, and consistent development offers fantastic value in challenging mechanical applications. These premium materials are effectively actualized in significant applications through fabric determination, provider assessment, and quality confirmation. High-quality titanium tubing outlives customary choices, requires less support, and performs way better.

FAQ

Q: What are the key differences between titanium grades for seamless tubes?

A: Grade 2 offers excellent general corrosion resistance and formability for standard applications, while Grade 7 provides enhanced resistance to reducing acids through palladium additions. Grade 9 incorporates aluminum and vanadium for higher strength applications, and Grade 12 offers improved performance in chloride environments with molybdenum and nickel additions.

Q: How does corrosion resistance compare between titanium and stainless steel tubing?

A: Titanium exhibits superior corrosion resistance across a broader range of chemicals and temperatures compared to stainless steel. Titanium remains immune to chloride-induced stress corrosion cracking and maintains protective properties in reducing acids, where stainless steel fails rapidly.

Q: What are typical lead times for custom titanium seamless tube orders?

A: Standard dimension tubes typically require 2-4 weeks for production and delivery, while custom dimensions may require 6-8 weeks, depending on complexity and quantity. Rush orders can often be accommodated with expedited processing for critical applications.

Q: What quality certifications should I expect from titanium tube suppliers?

A: Reputable suppliers provide ISO 9001:2015 certification along with complete material test reports, including chemical analysis, mechanical properties, and dimensional verification. ASTM specification compliance documentation should accompany all shipments.

Q: How do I determine the appropriate wall thickness for my application?

A: Wall thickness selection depends on operating pressure, temperature, and safety factors required for your specific application. Engineering calculations based on ASME pressure vessel codes or consultation with technical specialists help ensure proper sizing.

Contact Chuanghui Daye for Premium Titanium Seamless Tube Solutions

Shaanxi Chuanghui Daye stands ready to support your titanium seamless tube procurement needs with over 30 years of manufacturing expertise and comprehensive quality assurance. Our experienced technical team provides application-specific guidance, custom fabrication services, and reliable supply chain support for projects of any scale. Contact our specialists today at info@chdymetal.com to discuss your requirements, request technical data sheets, or obtain detailed quotations for your next project. As a trusted titanium seamless tube manufacturer, we deliver the quality, reliability, and service excellence that demanding industrial applications require.

References

1. American Society for Testing and Materials. "Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers." ASTM B338-18, 2018.

2. Boyer, Rodney R., and Ernest W. Collings. "Materials Properties Handbook: Titanium Alloys." ASM International, Materials Park, Ohio, 1994.

3. Peters, Manfred, and Christoph Leyens. "Titanium and Titanium Alloys: Fundamentals and Applications." Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany, 2003.

4. Schutz, Richard W. "Corrosion Resistance Properties of Titanium and Titanium Alloys in Chemical Process Industries." Materials Performance, Volume 45, Issue 7, 2006.

5. International Organization for Standardization. "Quality Management Systems - Requirements." ISO 9001:2015, Geneva, Switzerland, 2015.

6. Donachie, Matthew J. "Titanium: A Technical Guide, Second Edition." ASM International, Materials Park, Ohio, 2000.

Learn about our latest products and discounts through SMS or email