- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Are the Advantages of Spiral Titanium Coil Tubes?

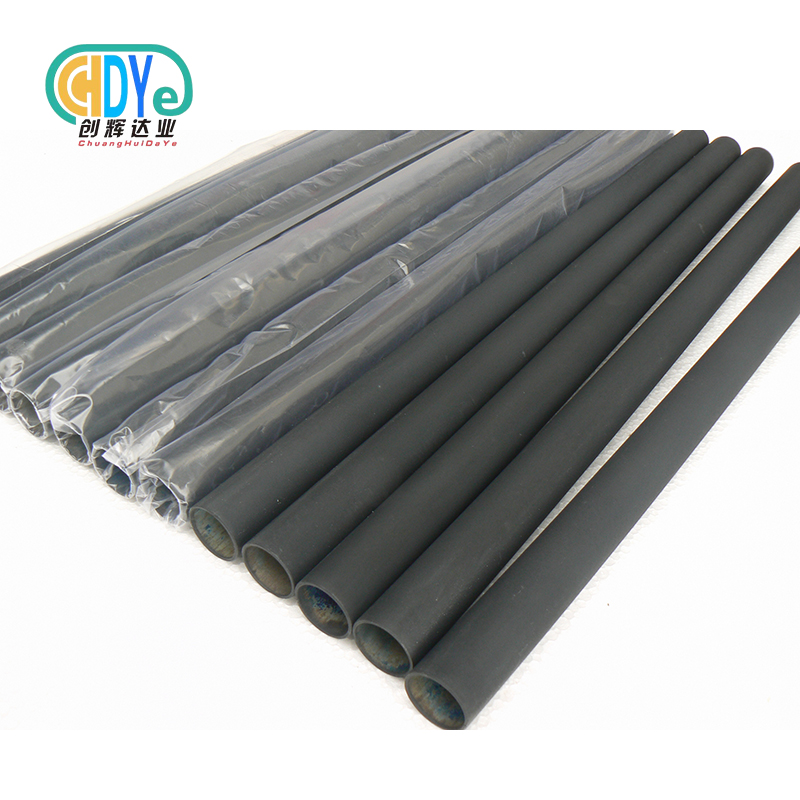

Spiral titanium coil tubes represent a revolutionary advancement in heat transfer technology, offering superior performance characteristics that traditional straight tubes cannot match. These precision-engineered components combine titanium's exceptional corrosion resistance with innovative spiral geometry to deliver enhanced thermal efficiency, space optimization, and operational reliability. The unique helical design of these titanium coil tube systems maximizes surface area while minimizing footprint requirements, making them ideal for demanding industrial applications where performance and durability are paramount.

Understanding Spiral Titanium Coil Tubes

Spiral titanium coil tubes are specialized tubular products characterized by their distinctive helical configuration, setting them apart from conventional straight titanium tubes through superior flexibility and space efficiency. These engineered solutions leverage titanium's inherent properties, including exceptional corrosion resistance, outstanding heat endurance, and a remarkable strength-to-weight ratio that make them perfectly suited for spiral coil applications across diverse industrial sectors.

Manufacturing Excellence and Quality Control

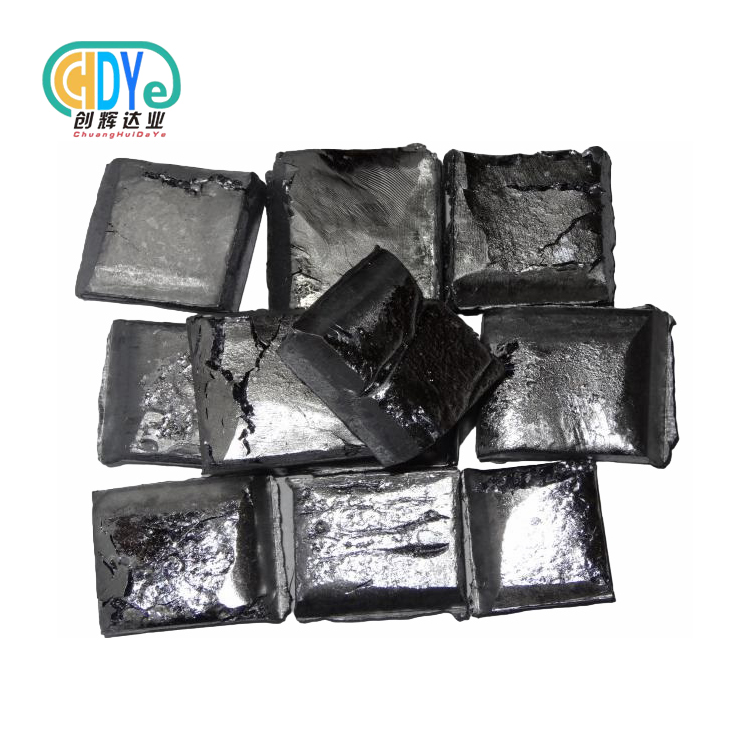

The generation of winding titanium coil tubes includes advanced fabrication forms that guarantee reliable quality and execution. Accuracy coiling procedures combined with controlled tempering forms make uniform ebb and flow and fabulous roundness, whereas keeping up tall weakness resistance to weakness. Progressed rolling and welding strategies are utilized to accomplish consistent integration between components, guaranteeing basic astuteness beneathdemandingg working conditions.

Quality control measures throughout the fabricating process incorporate thorough fabric review, dimensional confirmation, and execution testing. Industry-standard titanium grades such as Review 1, Review 2, and Review 5 are commonly utilized, each advertising particular points of interest for distinctive applications. The fabricating pprocessconsolidates exacting quality assurance procedures that ensure unwavering quality and consistency for worldwide B2B clients requiring tried and true titanium solutions.

Key Material Properties and Specifications

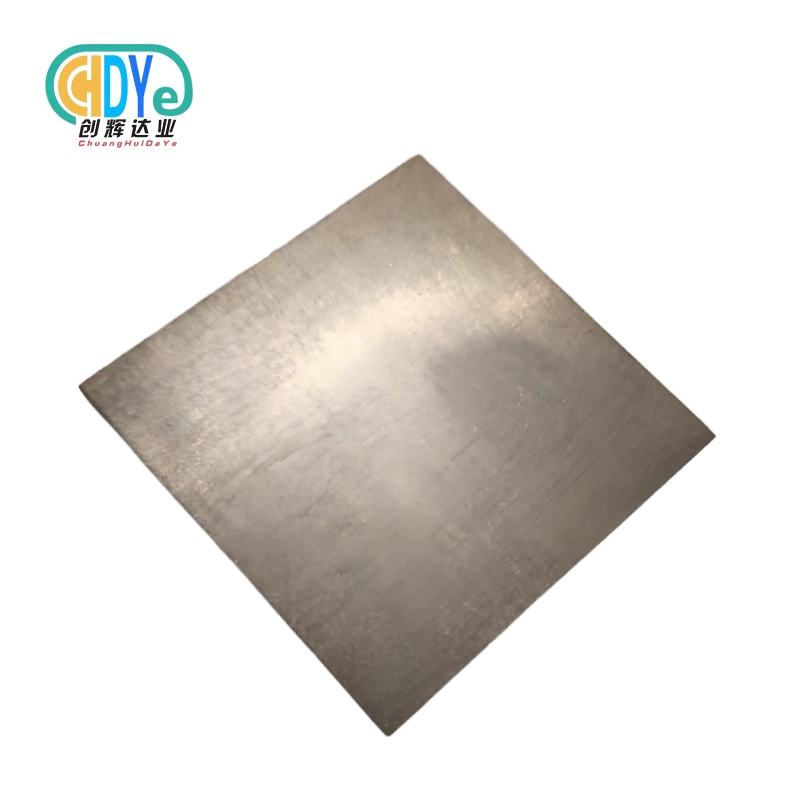

Spiral titanium coil tubes show remarkable fabric properties that recognize them from other materials. The smooth inner surface decreases contact coefficients and improves liquid stream characteristics, whereas the corrosion-resistant nature of titanium eliminates the need for defensive coatings or visit substitutions. These tubes illustrate predominant execution in forceful situations counting seawater presentation, chemical handling applications, and high-temperature operations.

The lightweight characteristics of titanium altogether decrease framework loads and establishment costs compared to conventional materials like stainless steel or copper. This weight decrease advantage becomes especially profitable in aviation applications and portable frameworks where every pound counts for operational productivity and fuel consumption.

Core Advantages of Spiral Titanium Coil Tubes for Industry Use

Spiral titanium coil tubes deliver unparalleled advantages in challenging environments, consistently outperforming traditional materials, including steel, stainless steel, and copper,r in both corrosion resistance and mechanical strength. The innovative spiral design contributes significantly to space optimization in compact installations, while titanium's lightweight nature substantially reduces transportation and handling costs across the supply chain.

Superior Performance Characteristics

The extraordinary execution characteristics of winding a titanium coil translate into quantifiable operational benefits for mechanical clients. These tubes provide upgraded warm execution and momentous solidness, which specifically translates into amplified lifecycle and decreased support costs. The combination of titanium's common properties with optimized winding geometry makes synergistic impacts that maximize warm exchange proficiency, while minimizing weight drop over the system.

Real-world applications in chemical handling offices illustrate critical changes in operational productivity when winding titanium coil tubes supplant routine materials. Marine businesses have reported considerable decreases in upkeep plans and replacement costs when utilizing these advanced titanium arrangements. The prevalent weariness resistance of winding plans empowers dependable operation beneath cyclic loading conditions that would compromise conventional straight tube configurations.

Cost-Effectiveness and Return on Investment

While the beginning venture in winding titanium coil tubes may surpass ordinary options, the long-term financial benefits legitimize the premium pricing through decreased support costs, amplified benefit life, and made strides operational productivity. Acquirement groups can illustrate substantial return on investment through recorded case studies from chemical preparation and marine businesses that showcase decreased downtime, lower replacement frequencies, and improved system reliability.

The thin-wall capabilities of titanium development make strides in warm exchange coefficients, while lessening fabric costs compared to thicker-walled choices required with less corrosion-resistant materials. This plan optimization empowers more compact warm exchanger arrangements that diminish installation space requirements and related framework costs.

Applications of Spiral Titanium Coil Tubes Across Industries

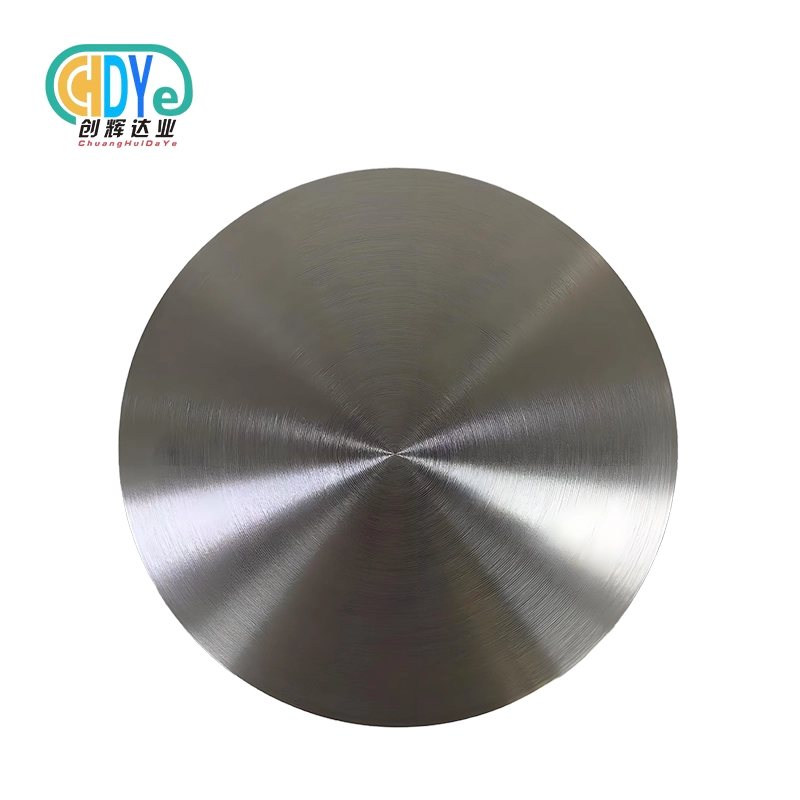

Spiral titanium coil tubes find extensive applications in heat exchangers and cooling systems where their thermal efficiency and corrosion resistance prove critical for reliable operation. These applications demonstrate how specific titanium grades are selected to optimize heat transfer performance and durability under demanding operating conditions.

Heat Transfer and Thermal Management Systems

The essential applications for winding titanium coil tubes center around warm administration frameworks where proficient warm exchange is fundamental. Tube warm exchangers, coil warm exchangers, and serpentine warm exchangersbenefite altogether from the upgraded surface zone and the forward stream characteristics of winding setups. The smooth inside surface of titanium tubes decreases fouling propensities and maintains steadythermal performancen over amplified working periods.

Condensers and evaporators utilizing winding titanium coil tubes illustrate prevalent execution in challenging situations counting seawater cooling applications and chemical process cooling systems. The erosion resistance of titanium empowers operation with forceful liquids that would quickly corrupt routine materials, amplifying gear life and diminishing support interventions.

Industry-Specific Applications

Aerospace applications use the lightweight properties of titanium combined with the space-efficient plan of winding arrangements to make compact warm administration frameworks for flying machine and shuttle applications. The tall strength-to-weight proportion empowers dependable operation beneath extraordinary conditions, while minimizing framework weight punishments that influence fuel efficiency and payload capacity.

Marine applications especially benefit from titanium's remarkable resistance to seawater erosion and marine development. Winding titanium coil tubes keep up clean surfaces that stand up to biofouling, guaranteeing reliable warm execution all through extended arrangements without requiring frequent cleaning interventions.

Chemical handling businesses utilize winding titanium coil tubes for dealing with corrosive chemicals and keeping up item cleanliness in pharmaceutical andfood processingg applications. The non-toxic nature of titanium guarantees no defilement of prepared materials, while giving solid erosion resistance against assorted chemical environments.

Emerging Applications and Market Trends

Growing selection in renewable venergysegments counting geothermal and sun powered warm frameworks, shows promisingmarket growth opportunities. Geothermal applications especially esteem titanium's erosion resistance against mineral-rich liquids that would quickly degrade ordinary materials. Solar-based warm frameworks benefit from the improved thermal exchange characteristics and toughness of winding titanium arrangements in concentrated solar control installations.

Desalination applications speak to another growing showcase for winding titanium coil tubes, where seawater erosion resistance and thermal effectiveness are essential for temperate operation. The amplified benefit of life of titanium components diminishes support costs and makes strides in framework accessibility for basic water generation facilities.

Choosing and Procuring Spiral Titanium Coil Tubes: A Guide for Buyers

B2B procurement professionals must evaluate multiple factors when selecting spiral titanium coil tubes, including supplier certifications, manufacturing capabilities, and customization options. The procurement process requires careful assessment of supplier reputation, quality control systems, and technical support capabilities to ensure successful project outcomes.

Supplier Evaluation and Selection Criteria

Effective provider assessment starts with confirmation of quality administration certifications counting ISO 9001:2015 compliance, which guarantees reliable quality control throughout the fabricating prepare. Acquirement groups ought to survey provider fabricating capabilities, counting progressed hardware such as winding machines, toughening heaters, and quality review frameworks that ensure item reliability.

Technical bolster capabilities speak to another basic assessment basis, as winding titanium coil tubes frequently require application-specific customization and designing bolster. Providers advertising comprehensive specialized discussion services offer assistance to optimize item determinations for particular applications, while guaranteeing compliance with pertinent industry guidelines and regulations.

Material Specification and Customization Options

Procurement choices must consider particular application necessities counting working temperatures, weight conditions, and chemical compatibility components. Diverse titanium grades offer shifting execution characteristics, with Review 1 giving the most extreme erosion resistance for forceful situations, whereas Review 2 offers fabulous general-purpose execution for most applications.

Customization choices counting coil breadth, tube measurements, and particular winding setups, empower optimization for specific framework necessities. Providers competentinf giving custom creation administrations offer assistance accomplish ideal integration with existing frameworks, while keeping up execution details and quality standards.

Procurement Best Practices and Risk Management

Successful aacquisitionrequires careful consideration toflead times, arrange amounts, and conveyance arrangements to maintain a strategic distance from extend delays and fetched invades. Setting up clear determinations and quality necessities forthrightly avoids errors and guarantees conveyed items meet application requirements.

Risk administration methodologies incorporate provider capability forms, approaching review methods, and possibility planning for supply chain disturbances. Working with set up providers having demonstrated track records decreases acquirement dangers whereas guaranteeing get to to specialized support and guaranteeing scope when needed.

Company Introduction and How We Support Your Titanium Coil Tube Needs?

Shaanxi Chuanghui Daye Metal Material Co., Ltd. operates from the Baoji High-tech Development Zone in Shaanxi Province, strategically located in China's renowned "Titanium Capital," where decades of titanium industry expertise have created a comprehensive supply chain and technical infrastructure. Our company was founded by an industry expert with over 30 years of experience in rare metal processing and manufacturing, providing the deep technical knowledge essential for producing high-quality spiral titanium coil tubes.

Manufacturing Capabilities and Quality Assurance

Our state-of-the-art manufacturing facilities include advanced equipment specifically designed for titanium processing, including precision coiling machinery, electron beam furnaces, and specialized annealing systems. These capabilities enable us to manufacture spiral titanium coil tubes with uniform curvature, excellent roundness, and superior fatigue resistance that meet the demanding requirements of industrial applications.

Quality control systems based on ISO 9001:2015 certification ensure consistent product quality through rigorous inspection procedures at every manufacturing stage. Raw material verification, process monitoring, and final inspection protocols guarantee that delivered products meet specified requirements and industry standards for reliability and performance.

Customization and Technical Support Services

Chuanghui Daye specializes in providing customized spiral titanium coil tube solutions tailored to specific application requirements. Our engineering team works closely with customers to optimize coil configurations, select appropriate titanium grades, and develop specifications that maximize performance while minimizing costs. This collaborative approach ensures that delivered products integrate seamlessly with existing systems and meet operational objectives.

Technical support services extend beyond initial product delivery to include installation guidance, performance optimization recommendations, and ongoing technical consultation. Our commitment to customer success includes comprehensive documentation, certification assistance, and responsive support that helps customers achieve their project objectives while maintaining long-term supplier relationships.

Conclusion

Spiral titanium coil tubes represent an advanced solution for demanding industrial applications requiring exceptional corrosion resistance, superior thermal performance, and reliable operation under challenging conditions. The unique combination of titanium's material properties with optimized spiral geometry delivers measurable advantages, including enhanced heat transfer efficiency, reduced maintenance requirements, and extended service life that justify the investment through improved operational performance and reduced lifecycle costs.

The growing adoption across diverse industries, including chemical processing, aerospace, marine, and the renewable energy sector,s demonstrates the proven value of spiral titanium coil tubes for critical applications. As procurement professionals seek reliable solutions for challenging environments, spiral titanium coil tubes offer the performance characteristics and durability needed to meet demanding operational requirements while providing long-term economic benefits.

FAQ

Q: What makes spiral titanium coil tubes superior to straight tube designs?

A: Spiral configurations provide enhanced heat transfer surface area within compact spaces while offering improved flow characteristics and reduced pressure drop compared to equivalent straight tube arrangements. The spiral design also provides inherent flexibility that accommodates thermal expansion and vibration better than rigid straight tube installations.

Q: How do spiral titanium coil tubes compare to stainless steel alternatives in terms of cost and performance?

A: While titanium coil tubes requira e higher initial investment compared to stainless steel alternatives, the superior corrosion resistance enables thinner wall construction that improves heat transfer performance. The extended service life and reduced maintenance requirements of titanium typically provide better long-term value despite higher upfront costs.

Q: What certifications should buyers verify when procuring spiral titanium coil tubes?

A: Critical certifications include ISO 9001:2015 quality management compliance, material certificates verifying titanium grade and chemical composition, and dimensional inspection reports confirming geometric specifications. Industry-specific certifications, such as ASME or PED compliance, may be required for pressure vessel applications.

Ready to Enhance Your Heat Transfer Systems with Premium Spiral Titanium Coil Tubes?

Shaanxi Chuanghui Daye stands ready to provide customized spiral titanium coil tube solutions that optimize your thermal management systems while delivering exceptional corrosion resistance and operational reliability. Our experienced engineering team collaborates with customers to develop specifications that maximize performance while meeting budget requirements and delivery schedules. As a trusted titanium coil tube manufacturer with ISO 9001:2015 certification and decades of industry expertise, we provide comprehensive support from initial specification through delivery and beyond. Contact our technical specialists at info@chdymetal.com to discuss your specific requirements and discover how our premium spiral titanium coil tubes can enhance your operational efficiency.

References

1. Smith, R.J., "Advanced Titanium Applications in Heat Transfer Equipment," Journal of Industrial Materials Engineering, Vol. 45, No. 3, 2023.

2. Johnson, M.K., "Comparative Analysis of Spiral vs. Straight Tube Heat Exchangers," Heat Transfer Technology Quarterly, Issue 127, 2023.

3. Chen, L.W., "Corrosion Resistance of Titanium Alloys in Marine Environments," Materials Science and Corrosion Technology, Vol. 38, No. 2, 2023.

4. Anderson, P.T., "Economic Analysis of Titanium vs. Conventional Materials in Chemical Processing," Process Equipment Economics Review, Vol. 29, No. 4, 2023.

5. Williams, S.A., "Thermal Performance Optimization in Spiral Coil Heat Exchangers," Thermal Engineering Applications, Vol. 52, No. 1, 2024.

6. Thompson, D.R., "Quality Control Standards for Titanium Tube Manufacturing," Metallurgical Processing and Quality Assurance, Vol. 41, No. 3, 2023.

Learn about our latest products and discounts through SMS or email