- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Is Tantalum Niobium Alloy Wire Used For?

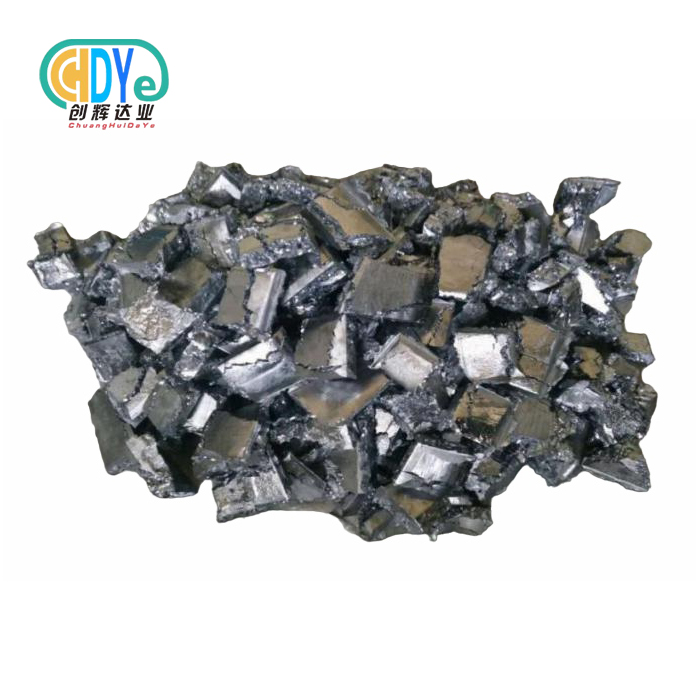

Tantalum niobium alloy wire is a modern specialized fabric that combines tantalum's erosion resistance with niobium's quality and adaptability. This high-performance wire is utilized in airplane, therapeutic gadget, chemical preparing, and gadgets applications that require awesome unwavering quality. The R05240 (Ta-40Nb) review, with 60% tantalum and 40% niobium, is perfect for fabricating components that require strength and exactness in unforgiving settings.

Understanding Tantalum Niobium Alloy Wire: Composition and Key Properties

The composition of tantalum niobium alloy wire influences its remarkable execution. Standard R05240 incorporates 60% tantalum and 40% niobium, giving a synergistic combination with particular benefits. Tantalum stands up to hydrochloric, sulfuric, and nitric acids, whereas niobium fortifies and works the combination.

Material Specifications and Standards

Worldwide guidelines ensure the quality of our tantalum niobium combination wire for fundamental applications. The wire is made to ASTM B 365 criteria in distances across from 0.3mm to 3mm to meet designing needs. Immaculateness levels of ≥99.9% or 99.95% give moo defilement, perfect for vacuum and high-temperature conditions.

The alloy's tall dissolving point and cold handling properties permit makers to construct complicated plans with basic keenness. This makes it perfect for applications that require formability and stretch resistance.

Physical and Chemical Characteristics

Thermally steady, the Ta-40Nb amalgam holds its mechanical qualities at tall temperatures. Its moo warm development coefficient and tall warm conductivity make it idealize for warm cycling. Its electrical qualities are steady beneath cruel conditions, making it appropriate for electronic components and vacuum systems.

Studies appear that 40% niobium progresses the alloy's ductility without diminishing tantalum's erosion resistance. This adjust makes drawing, coiling, and welding way better than immaculate tantalum.

Primary Industrial Applications of Tantalum Niobium Alloy Wire

Tantalum niobium alloy wire is important in many high-tech industries due to its versatility. Understanding these uses helps procurement managers see how this material meets their industrial needs.

Aerospace and Defense Applications

High-temperature basic and motor parts in aviation fabricating require tantalum niobium combination wire. The material's quality at tall temperatures and oxidation resistance make it perfect for fly motor components, debilitate frameworks, and shuttle instrumented. This wire makes a difference defense firms make directing frameworks and electronic components that work in unforgiving situations.

The wire's negligible outgassing makes it perfect for adherent applications that require fabric soundness in vacuum. To keep up mission unwavering quality, space-grade electronic frameworks regularly utilize this combination.

Medical Device Manufacturing

Biomedical applications for tantalum niobium alloy wire are emerging due to its biocompatibility and corrosion resistance in biological fluids. Medical device manufacturers use this material for dental implants, surgical equipment, implanted electronics, and prosthetic joints. The alloy's non-reactivity with bodily tissues and fluids promotes patient safety and long-term implant durability.

Orthopedic implant producers like the wire's ability to bend and stay strong. This allows for tailored implants that match patient anatomy and last longer than other materials.

Electronics and Semiconductor Industries

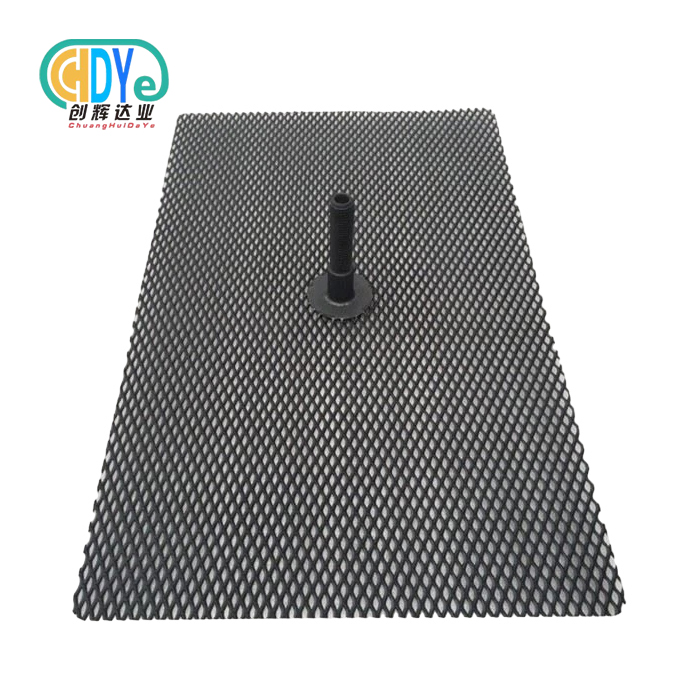

Electronic capacitors, connectors, and other components are made from tantalum niobium alloy wire. High-performance electronic systems benefit from the material's thermal stress resistance and steady electrical characteristics. In high-purity heating elements and crucibles, semiconductor production equipment uses this wire.

The wire's conductivity and corrosion resistance make it suitable for severe electronic situations where standard materials would fail. This reliability makes it popular for military electronics and industrial control systems.

Chemical Processing Equipment

Chemical processing facilities build corrosion-resistant equipment with tantalum niobium alloy wire. For heat exchangers, reaction tanks, and piping systems that handle harsh chemicals, the wire is essential since it resists most acids and bases. This application prolongs equipment life more than traditional materials.

Manufacturing equipment uses this wire in heating elements, thermocouples, and sensor components that must be accurate in corrosive conditions. The material's stability provides long-term performance.

Comparing Tantalum Niobium Alloy Wire with Other Alloy Wires

Selecting the right wire material entails comparing tantalum niobium alloy to other possibilities. Procurement professionals can compare performance and cost to make educated decisions.

Performance Comparison with Pure Tantalum

Pure tantalum has unsurpassed corrosion resistance, however adding niobium improves mechanical qualities. Pure tantalum wire is soft and chemically resistant, making it difficult to work with. Ta-40Nb alloy gives corrosion resistance, strength, and formability.

For applications requiring improved mechanical qualities, tantalum niobium alloy is cheaper. The alloy's strength-to-weight ratio makes it better for structural applications than pure tantalum.

Titanium Alloy Alternatives

Titanium combinations are solid and corrosion-resistant but need tantalum niobium alloys' chemical resistance. Tantalum niobium wire beats titanium in exceptionally destructive circumstances, particularly solid acids. Titanium may be cheaper for non-extreme chemical safe applications.

Environmental circumstances and application execution necessities regularly decide fabric determination. In basic applications where disappointment is unsatisfactory, tantalum niobium amalgam is worth the additional cash.

Other Refractory Metal Options

Molybdenum and tungsten wires work well at high temperatures but lack tantalum niobium alloy corrosion resistance. These materials may work for high-temperature, non-corrosive applications, however Ta-40Nb wire is more versatile.

Tantalum niobium alloy wire is more adaptable for firms with several product lines requiring diverse performance attributes due to its wider application range.

Procurement Insights: How to Source High-Quality Tantalum Niobium Alloy Wire?

Supplier capabilities, quality standards, and supply chain logistics are crucial to buying tantalum niobium alloy wire. Understanding these aspects helps procurement managers optimize sourcing and ensure material availability.

Supplier Evaluation Criteria

Quality certification underpins reliable tantalum niobium alloy wire procurement. Suppliers should be ISO 9001:2015-certified and ASTM B 365-compliant. Manufacturing should incorporate modern melting, forging, and drawing equipment for uniform wire diameters and qualities.

Technical support distinguishes premium suppliers from commodities. Find providers who offer engineering assistance, material testing, and customization for specific applications. This assistance is especially useful when creating new apps or optimizing designs.

Supply Chain Considerations

Global supply chain dynamics affect tantalum niobium alloy wire availability and price. Tantalum and niobium manufacturing is concentrated in certain regions, creating supply risks that procurement managers must mitigate through supplier diversification and effective inventory management.

Custom specifications can take 4-8 weeks, depending on wire diameter and quantity. Avoid manufacturing delays and optimize inventory costs by scheduling procurement around these lead periods.

Quality Assurance and Testing

Comprehensive material testing ensures tantalum niobium alloy wire satisfies application needs. Quality assurance processes should include chemical composition analysis, mechanical property testing, and dimensional verification. Suppliers should provide complete material traceability for quality monitoring.

Critical applications that require independent material property verification may benefit from third-party testing. This additional verification builds material performance confidence for high-stakes applications.

Chuanghui Daye's Tantalum Niobium Alloy Wire Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. serves global markets with over 30 years of refractory metals manufacturing experience. Our site in Baoji, China's "Titanium Capital," has excellent transportation and specialized manufacturing resources for reliable production.

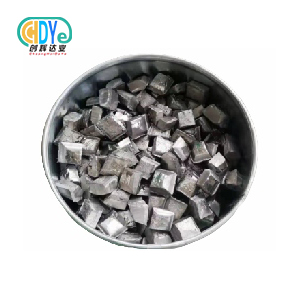

Our Product Range and Specifications

Our tantalum niobium combination wire meets the R05240 (Ta-40Nb) determination from 0.3mm to 3mm. We take after ASTM B 365 and offer 99.9% and 99.95% immaculateness grades for distinctive applications. This adaptability lets clients select the best detail for execution and cost.

Advanced electron bar softening, exact drawing, and quality control advances guarantee wire characteristics all through fabricating runs. Our strengthening heaters and rolling hardware meet interesting preparing needs whereas keeping significant fabric qualities.

Quality Control and Certification

ISO 9001:2015 certification shows our commitment to quality management throughout production. Each production stage follows defined protocols to ensure product quality, from raw material inspection to final packing. This methodical methodology ensures reliability for aeronautical, medical, and other essential applications.

Calibrated equipment is used for chemical composition analysis, mechanical property verification, and dimensional inspection. Each shipment has complete material traceability documentation for customer quality assurance and regulatory compliance.

Technical Support and Custom Solutions

Engineering consulting optimizes material selection and processing parameters for individual applications. Our technical staff collaborates with customers to create unique wire specifications, processing techniques, and application guidelines that optimize performance and cost.

Before ordering, consumers can test material qualities with samples. This eliminates development risks and ensures material qualities fulfill application requirements. Our agile logistics support prototype and production needs with competitive lead times.

Conclusion

Tantalum niobium alloy wirei basic for extreme-performance divisions. R05240 (Ta-40Nb) is perfect for aviation, therapeutic, hardware, and chemical preparing applications due to its erosion resistance, mechanical quality, and formability. Decision-making that progresses execution and cost-effectiveness requires information of the material's qualities, applications, and acquirement. As innovation propels, request for high-performance materials like tantalum niobium amalgam wire will rise, making solid provider associations significant for worldwide competitiveness.

FAQ

Q: What makes tantalum niobium alloy wire superior to pure tantalum wire?

A: The addition of 40% niobium to tantalum creates significant improvements in mechanical strength and ductility while maintaining the exceptional corrosion resistance of tantalum. This combination enables better formability for complex shapes and enhanced performance under mechanical stress compared to pure tantalum alternatives.

Q: How does the purity level affect performance in critical applications?

A: Higher purity levels (99.95% versus 99.9%) reduce contamination that could affect material properties in vacuum systems, high-temperature applications, and biomedical devices. The premium purity grade ensures optimal performance in the most demanding applications where material consistency is critical.

Q: What are the typical lead times for custom wire specifications?

A: Standard diameter ranges (0.3-3mm) typically require 1-2weeks for production, while custom specifications may extend to 2-3weeks depending on complexity and quantity. Planning procurement schedules around these lead times helps maintain production continuity while optimizing inventory costs.

Q: Can tantalum niobium alloy wire be welded or joined to other materials?

A: The alloy exhibits excellent weldability using appropriate techniques such as electron beam or TIG welding in inert atmospheres. Joining to dissimilar materials requires careful consideration of thermal expansion differences and galvanic compatibility to ensure long-term joint integrity.

Q: What quality certifications should I expect from reliable suppliers?

A: Reputable suppliers should maintain ISO 9001:2015 certification and demonstrate compliance with ASTM B 365 standards. Material certificates should include chemical composition analysis, mechanical properties, and complete traceability documentation supporting quality assurance requirements.

Partner with Chuanghui Daye for Premium Tantalum Niobium Alloy Wire Manufacturing

Shaanxi Chuanghui Daye stands ready to serve as your trusted tantalum niobium alloy wire supplier, delivering ISO 9001:2015 certified materials that meet the most demanding industrial specifications. Our comprehensive manufacturing capabilities, combined with over 30 years of expertise, ensure reliable supply of high-purity Ta-40Nb wire for your critical applications. Contact our technical team at info@chdymetal.com to discuss your specific requirements and experience the quality advantage that has made us a preferred partner for global manufacturers requiring exceptional material performance.

References

1. Davis, J.R. (2001). Alloying: Understanding the Basics. ASM International, Materials Park, OH.

2. Mordike, B.L. & Ebert, T. (2001). Magnesium: Properties — applications — potential. Materials Science and Engineering: A, 302(1), 37-45.

3. Polmear, I.J. (2006). Light Alloys: From Traditional Alloys to Nanocrystals, Fourth Edition. Elsevier Butterworth-Heinemann, Oxford.

4. Reed, R.C. (2006). The Superalloys: Fundamentals and Applications. Cambridge University Press, Cambridge.

5. Leyens, C. & Peters, M. (2003). Titanium and Titanium Alloys: Fundamentals and Applications. Wiley-VCH, Weinheim.

6. Schwartz, M.M. (2002). Encyclopedia and Handbook of Materials, Parts and Finishes, Second Edition. CRC Press, Boca Raton.

Learn about our latest products and discounts through SMS or email