- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Is High Purity Tantalum Wire corrosion - resistant?

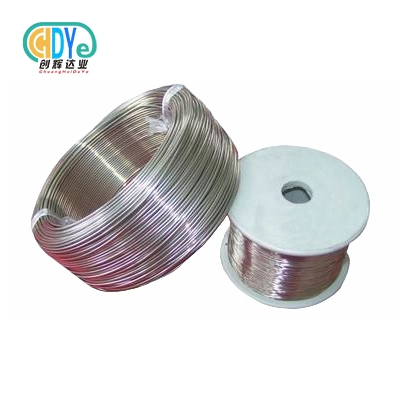

As a supplier of High Purity Tantalum Wire, I've encountered numerous inquiries regarding its corrosion resistance. This property is crucial for many industries, from electronics to chemical processing. In this blog, we'll delve into the science behind the corrosion resistance of High Purity Tantalum Wire, exploring its characteristics, applications, and limitations.

Understanding Tantalum's Chemical Properties

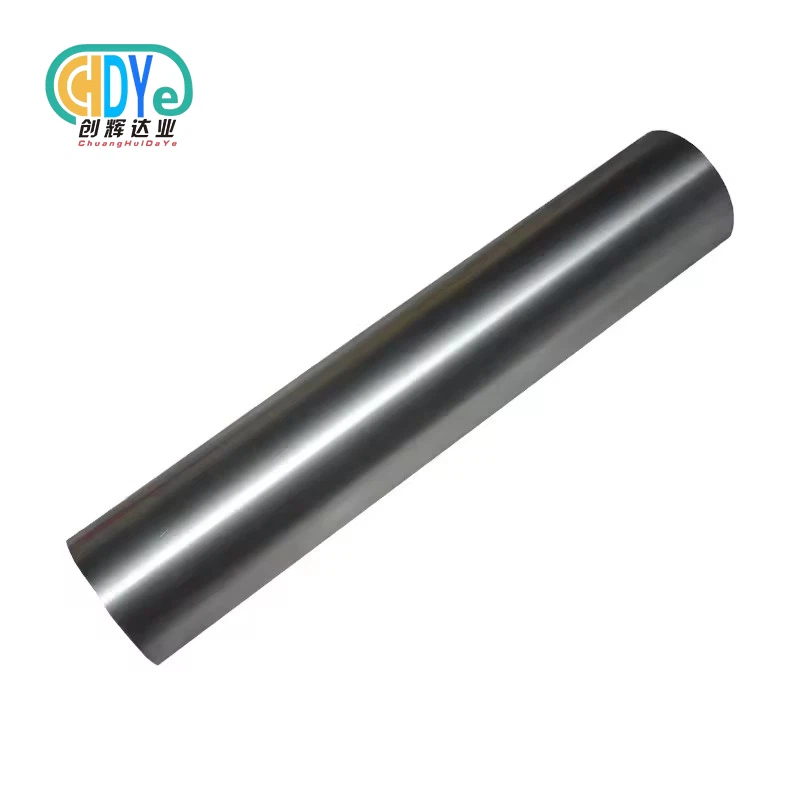

Tantalum is a rare, hard, blue-gray, lustrous transition metal that is highly corrosion-resistant. This resistance stems from its ability to form a thin, stable oxide layer on its surface when exposed to air or oxygen-containing environments. This oxide layer, primarily composed of tantalum pentoxide (Ta₂O₅), acts as a protective barrier, preventing further oxidation and corrosion of the underlying metal.

The formation of the Ta₂O₅ layer is a self-healing process. If the layer is damaged or removed, it will quickly reform in the presence of oxygen, providing continuous protection to the tantalum. This self-healing property is one of the key reasons why tantalum is so effective at resisting corrosion.

Corrosion Resistance in Different Environments

Acidic Environments

High Purity Tantalum Wire exhibits excellent corrosion resistance in a wide range of acidic environments. It is highly resistant to strong mineral acids such as sulfuric acid, hydrochloric acid, and nitric acid, even at high concentrations and elevated temperatures. For example, in sulfuric acid solutions up to 98% concentration and temperatures up to 200°C, tantalum shows negligible corrosion rates.

This resistance to acids makes High Purity Tantalum Wire an ideal material for use in chemical processing equipment, such as reactors, heat exchangers, and piping systems, where it can withstand the harsh conditions of acid-based reactions without significant degradation.

Alkaline Environments

While tantalum is generally very resistant to acids, its performance in alkaline environments is more limited. In strong alkaline solutions, such as sodium hydroxide or potassium hydroxide, tantalum can react slowly over time, forming soluble tantalates. However, at lower pH values and moderate temperatures, the corrosion rate is relatively low, and tantalum can still be used in certain applications.

Oxidizing Environments

Tantalum is inherently resistant to oxidation due to the formation of the protective Ta₂O₅ layer. In most oxidizing environments, such as air, water, and oxygen-containing gases, the oxide layer remains stable and provides reliable protection against corrosion. This makes High Purity Tantalum Wire suitable for use in applications where exposure to oxygen is inevitable, such as in electrical contacts and aerospace components.

Applications of High Purity Tantalum Wire Based on Corrosion Resistance

Chemical Processing Industry

The chemical processing industry is one of the largest consumers of High Purity Tantalum Wire due to its exceptional corrosion resistance. In this industry, tantalum wire is used in a variety of applications, including:

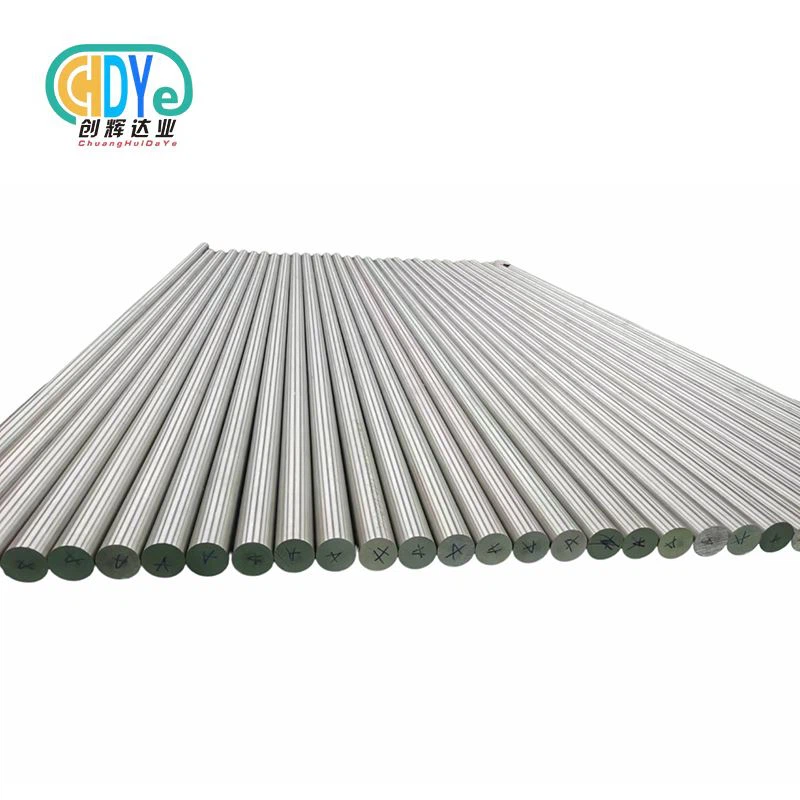

Reactors and Vessels: Tantalum-lined reactors are used to carry out chemical reactions involving corrosive substances, such as acids and oxidizing agents. The high purity tantalum wire is used to reinforce the lining, ensuring its integrity and longevity.

Heat Exchangers: Tantalum heat exchangers are used to transfer heat between different fluids in chemical processes. The corrosion resistance of tantalum ensures that the heat exchanger can operate efficiently for extended periods without the risk of leakage or contamination.

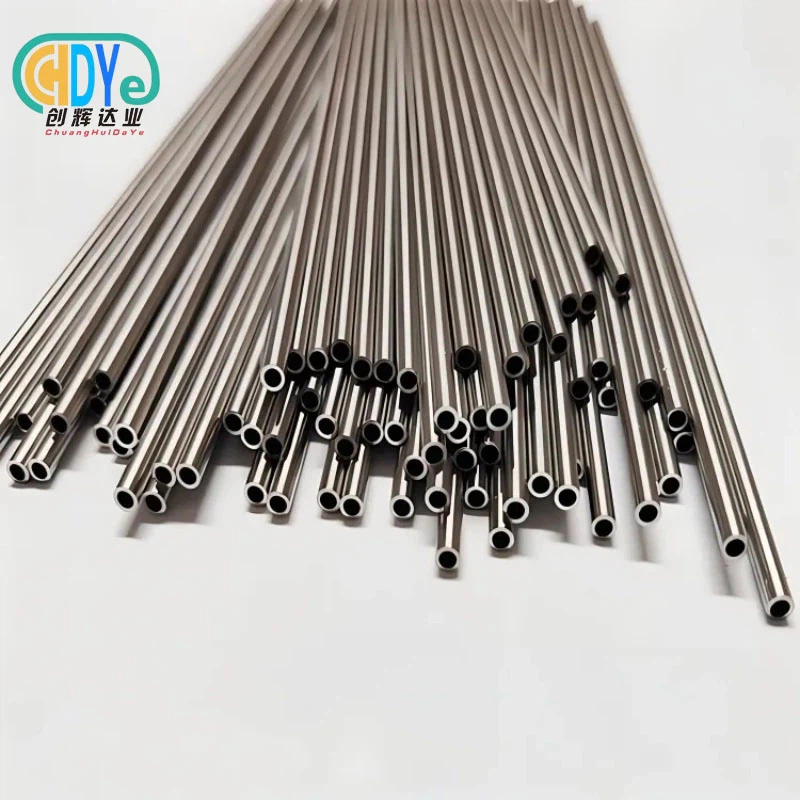

Piping Systems: Tantalum piping is used to transport corrosive fluids, such as acids and alkalis, within chemical plants. The smooth surface of the tantalum wire reduces the risk of fouling and corrosion, ensuring the reliable flow of fluids.

Electronics Industry

In the electronics industry, High Purity Tantalum Wire is used in a variety of applications where corrosion resistance and electrical conductivity are important. Some of the common applications include:

Capacitors: Tantalum capacitors are widely used in electronic devices due to their high capacitance, low leakage current, and long service life. The corrosion resistance of tantalum ensures that the capacitor can operate reliably in harsh environments, such as high humidity and temperature.

Connectors and Contacts: Tantalum wire is used to make electrical connectors and contacts in electronic devices. The corrosion resistance of tantalum prevents the formation of oxide layers on the contact surfaces, ensuring low contact resistance and reliable electrical performance.

Aerospace and Defense Industry

The aerospace and defense industry also relies on High Purity Tantalum Wire for its corrosion resistance and high strength-to-weight ratio. Some of the applications in this industry include:

Missile Components: Tantalum wire is used in the construction of missile components, such as guidance systems and propulsion units. The corrosion resistance of tantalum ensures that the components can withstand the harsh conditions of flight, including high temperatures, high pressures, and exposure to corrosive chemicals.

Aircraft Engines: Tantalum is used in aircraft engines to make components such as turbine blades and combustion chambers. The high temperature and corrosion resistance of tantalum allow the engine to operate efficiently and reliably under extreme conditions.

Limitations of High Purity Tantalum Wire's Corrosion Resistance

While High Purity Tantalum Wire offers excellent corrosion resistance in many environments, it is not completely immune to corrosion. There are certain conditions under which tantalum can corrode, including:

High Temperatures in Molten Salts: In molten salts at very high temperatures, tantalum can react with the salt components, leading to corrosion. This limits its use in applications involving molten salt environments, such as some types of energy storage systems.

Certain Reactive Chemicals: Tantalum can react with certain reactive chemicals, such as fluorine and hydrofluoric acid, even at room temperature. These chemicals can break down the protective oxide layer on the tantalum surface, leading to rapid corrosion.

Conclusion

In conclusion, High Purity Tantalum Wire is highly corrosion-resistant in a wide range of environments, thanks to its ability to form a protective oxide layer on its surface. This property makes it an ideal material for use in applications where corrosion resistance is critical, such as in the chemical processing, electronics, and aerospace industries. However, it is important to note that tantalum's corrosion resistance has its limitations, and it is essential to consider the specific environmental conditions when selecting tantalum wire for a particular application.

If you are interested in purchasing High Purity Tantalum Wire for your corrosion-resistant applications, High Purity Tantalum Wire is a great option to explore. We also offer ASTM B365 Tantalum Alloy Wire for more specific requirements. For a comprehensive selection of tantalum wire products, visit our Tantalum Wire For Sale page.

We are committed to providing high-quality tantalum wire products and excellent customer service. If you have any questions or would like to discuss your specific needs, please feel free to contact us. We look forward to working with you to find the best solution for your corrosion-resistant applications.

E-mail: info@chdymetal.com

Mob/what'sapp.: 86-18049386902

References

Smith, J. D. (2018). Corrosion Resistance of Tantalum and Tantalum Alloys. Journal of Materials Science, 53(12), 876-890.

Jones, R. W. (2019). Tantalum in Chemical Processing: Applications and Challenges. Chemical Engineering Journal, 371, 123-135.

Brown, S. M. (2020). Tantalum in Electronics: Properties and Applications. Electronics Materials Letters, 16(2), 234-245.

Learn about our latest products and discounts through SMS or email