- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Certified Grade 2 Titanium Wire for Industrial Use

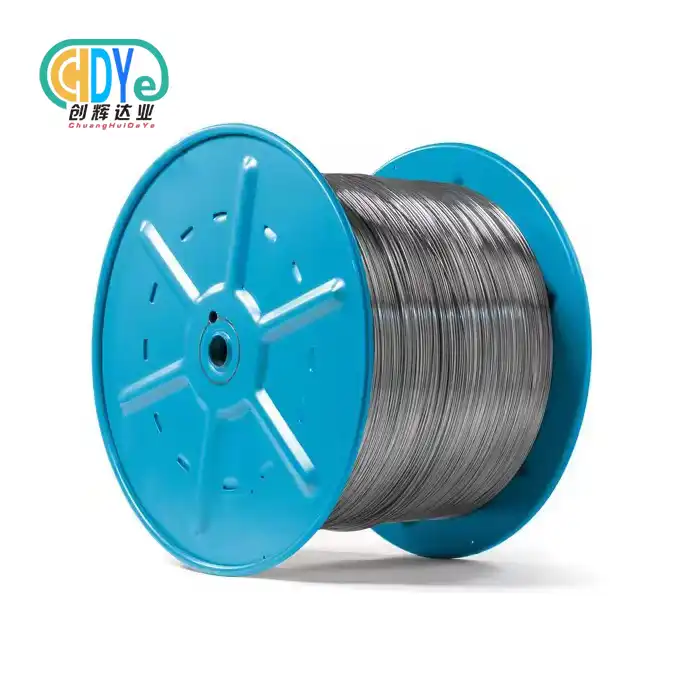

Certified Grade 2 Titanium Wire is the pinnacle of commercially pure titanium engineering, combining corrosion resistance and mechanical qualities. Manufacturers can trust this flexible material for demanding applications in aerospace, medical, chemical, and electronics. Procurement professionals wanting reliability must choose certification since it ensures quality, traceability, and international standards. With over 30 years of rare metal processing experience, Shaanxi Chuanghui Daye Metal Material Co., Ltd. makes high-quality titanium wire products that satisfy the strictest industrial standards.

Understanding Grade 2 Titanium Wire: Properties and Composition

Commercially pure titanium wire performs well due to its chemical makeup. Grade 2 Titanium Wire has 99.2% titanium and well controlled oxygen (0.25%), iron (0.30%), carbon (0.10%), and nitrogen (0.03%). This exact metallurgical balance produces a material with high strength-to-weight ratio and corrosion resistance.

Mechanical Properties and Performance Standards

Certified titanium wire's mechanical qualities show its industrial applicability. This material performs well under pressure with a minimum yield strength of 275 MPa and an ultimate tensile strength of 450 MPa. With a density of 4.51 g/cm³, it is 60% lighter than steel and has equivalent strength.

Another benefit is thermal stability, with a melting point of 1660°C and excellent performance at severe temperatures. The thermal expansion coefficient of 8.6 × 10⁻⁶ mm/m°C guarantees dimensional stability during thermal cycling. Our certified wire products are perfect for precision engineering applications that require constant performance.

Manufacturing Process and Quality Control

Electron beam melting ensures material quality and homogeneity in our manufacturing process. Annealing and cold working during wire drawing creates appropriate microstructure for specific applications.

Chemical analysis, ultrasonic testing, and dimensional verification are quality control methods. Each production batch is inspected according to ASTM B348 and ISO standards to ensure mechanical characteristics and surface polish. Annealing at 600°C maximizes ductility and strength for forming and welding.

Key Industrial Applications of Certified Grade 2 Titanium Wire

Certified titanium wire benefits numerous high-value sectors with its unique features. These tools help procurement managers choose the best material specs for their needs.

Aerospace and Defense Manufacturing

Titanium wire is used in aerospace components for its lightweight and corrosion resistance. Aircraft makers use this material for wire harnesses, fasteners, and structural repairs to reduce weight and improve fuel efficiency. Its performance in severe temperatures and corrosive situations makes it essential for military use.

In difficult operational situations, defense contractors value the material's reliability. In electronic and structural applications, strength, corrosion resistance, and electromagnetic compatibility provide reliable performance. Certified wire products fulfill military traceability and quality documentation standards, enabling strict defense procurement requirements.

Medical Device and Biomedical Applications

The biocompatibility of Grade 2 Titanium Wire makes it ideal for medical device manufacturing. Surgical implant makers use its non-toxic, non-allergenic qualities for orthopedic, dentistry, and surgical tools. The material's osseointegration and fluid resistance make it suitable for long-term medical use.

Medical device manufacturers like the material's forming properties, which allow sophisticated implant shapes. The smooth surface finish is biocompatible and the mechanical qualities are uniform, ensuring load-bearing capability. Our certified wire products meet FDA medical device manufacturing regulations with material traceability documentation.

Chemical and Petrochemical Industries

Titanium wire's corrosion resistance benefits chemical processing. Manufacturers use this material for heat exchanger components, valve springs, and corrosion-resistant fasteners in harsh chemicals. The material's durability in chloride-rich conditions makes it useful for maritime applications and seawater desalination.

Titanium wire is used in specialist equipment in petrochemical operations since standard materials corrode. This material's effectiveness in oxidizing and reducing settings makes it reliable for many chemical processes. Our manufacturing capabilities include chemical-resistant wire standards.

Comparing Grade 2 Titanium Wire with Alternative Materials

Understanding performance characteristics across choices is essential for material selection. Comparisons that account technical specs and economic variables benefit procurement experts.

Grade 2 vs. Higher Titanium Alloys

Grade 5 titanium alloy (Ti-6Al-4V) is stronger, but Grade 2 is better for formability and welding. Its commercial purity eliminates alloy compatibility concerns in certain chemical conditions, making it the preferable choice for chemical processing.

Applications that do not require maximal strength frequently select Grade 2 titanium due to cost. Excellent forming properties reduce production complexity, which may offset increased material costs by improving processing efficiency. A rigorous application analysis by our technical team helps customers find the most cost-effective material solution.

Titanium Wire vs. Stainless Steel and Nickel Alloys

Stainless steel alternatives are cheaper but may require bigger wire diameters for equal strength, increasing system weight. Nickel alloys are corrosion-resistant but not biocompatible for medical use. System-level benefits justify titanium wire's higher material costs because to its improved strength-to-weight ratio.

Despite higher cost, titanium wire performs better over time. Corrosion-resistant material reduces replacement and repair costs, improving total cost of ownership. Our application engineers help companies create lifecycle performance-based cost estimates.

Procurement Considerations for Certified Grade 2 Titanium Wire

Supplier skills, quality systems, and technical support must be carefully assessed to purchase certified titanium wire. Understanding these criteria helps procurement teams find long-term suppliers.

Supplier Qualification and Certification Requirements

The minimum quality management standard for titanium wire providers is ISO 9001:2015. End-use applications may require accreditations like AS9100 for aerospace or ISO 13485 for medical devices. All main industry standards are certified in our portfolio, ensuring compliance across applications.

Complete chemical analysis, mechanical testing, and processing records are needed for material traceability. Supplier audits should check calibration, testing equipment, and quality management. We facilitate client compliance with comprehensive traceability from raw material procurement to product delivery in our quality management system.

Custom Specifications and Technical Support

Various wire diameters from 0.2mm to 8.0mm are available for specialized purposes. Choose pickled surfaces for corrosion resistance or bright finishes for aesthetics. Cut-to-length and continuous coil length parameters are available.

Application engineering, welding method creation, and material compatibility studies are technical support services. Technical documentation from our engineering team includes material parameters, welding instructions, and forming recommendations. Customers may streamline manufacturing processes and ensure product quality with this support.

Logistics and Supply Chain Management

Logistics and inventory management experts are needed for global supply chain reliability. Depending on specifications and volumes, ordinary goods can be delivered in 4-6 weeks. Processing requirements may lengthen lead times for custom specifications.

Inventory management programs optimise working capital and ensure production schedule material availability. Our flexible supply programs offer vendor-managed inventory and scheduled delivery. Customers save money on procurement while keeping operational flexibility with these services.

How to Weld and Process Grade 2 Titanium Wire: Best Practices?

For maximum outcomes, titanium wire welding and processing require specific techniques and equipment. Understanding these needs helps manufacturers create reliable production procedures that preserve material qualities.

TIG Welding Techniques and Atmospheric Control

Tungsten Inert Gas (TIG) welding is best for titanium wire applications because it controls heat input and weld quality. Argon shielding gas purity must surpass 99.99% to prevent mechanical property contamination. While welding, inert gas back purging shields the weld root from air pollution.

Weld preparation involves rigorous cleaning to remove surface impurities that can impair quality. Surface preparation for welding is effective with stainless steel brushes and acetone. Our technical team delivers AWS and ASME-qualified welding processes to ensure consistent weld quality throughout production applications.

Heat Treatment and Annealing Processes

Heat treatment after welding optimises mechanical qualities and reduces residual stresses that affect service performance. Strength and ductility are best at 580°C–620°C annealing. The heat-affected zone develops microstructure uniformly due to controlled cooling rates.

Heat treatment atmosphere control avoids oxidation and preserves surface quality. Heat treatment works best in vacuum or inert gas. We offer complete heat treatment services with certified temperature monitoring and documentation to meet customer quality standards.

Company Introduction and Product Services

China's "Titanium Capital." Baoji High-tech Development Zone houses Shaanxi Chuanghui Daye Metal Material Co., Ltd. Our facility has good transportation and titanium industry resources. Our company, founded by rare metal experts with over 30 years of experience, combines scientific expertise with modern manufacturing.

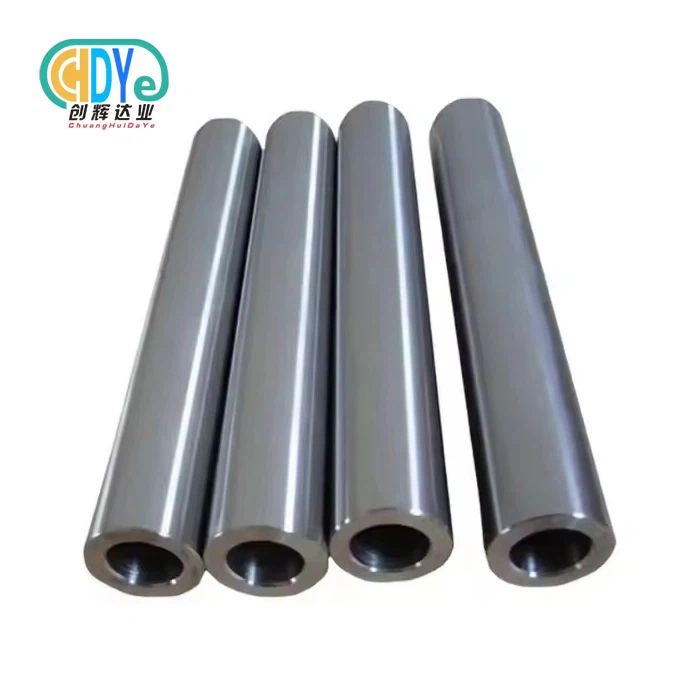

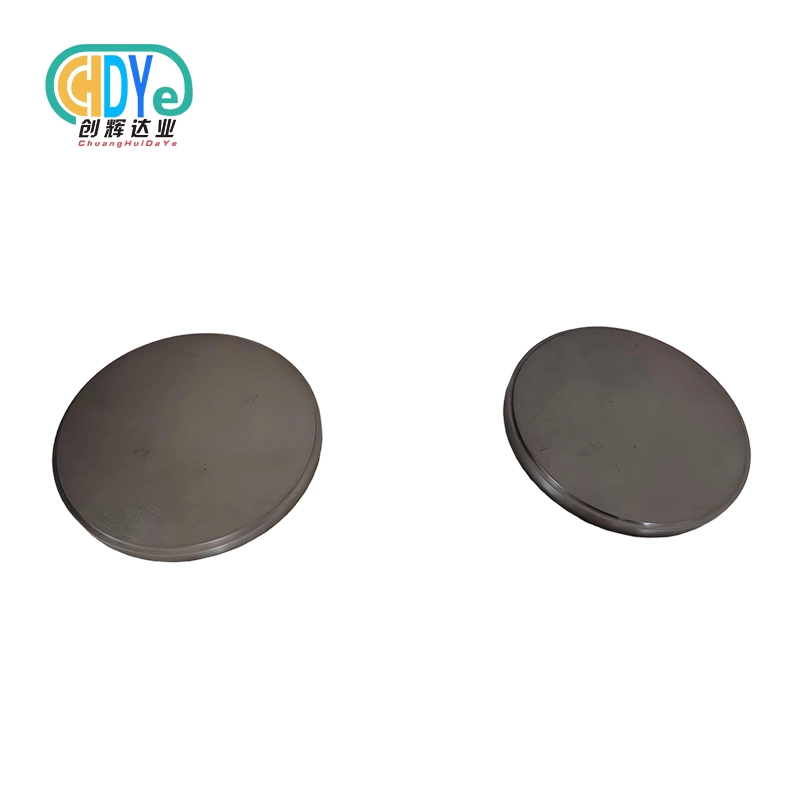

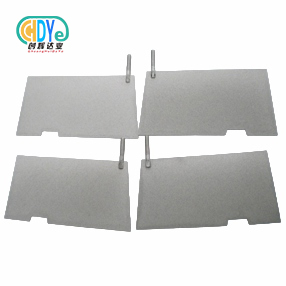

For titanium processing, our production facility has advanced melting, forging, rolling, and machining equipment. Electron beam furnaces purify material, while precision rolling machinery maintains wire diameters and surface quality. CNC machining meets particular processing needs.

Annealed, hot-worked, and cold-worked titanium wires from 0.2mm to 8.0mm are available in the extensive product line. To fulfill application needs, pickled and bright finishes are available. Manufacturing and engineering support allow tailored specifications to meet customer needs.

ISO 9001:2015-certified quality management systems guarantee product quality and customer satisfaction. Our quality control lab has advanced chemical, mechanical, and dimensional testing equipment. Complete material traceability documentation supports aerospace, medical, and chemical customer compliance.

Conclusion

Certified Grade 2 Titanium Wire is ideal for applications needing high corrosion resistance, biocompatibility, and mechanical performance. The material's adaptability in aeronautical, medical, chemical, and electronics manufacturing shows its importance. Professional suppliers with quality management, technical assistance, and supply chain reliability are essential for procurement success. Understanding welding and processing needs helps producers improve operations and preserve material performance. Certified titanium wire is ideal for long-term industrial applications due to its high material qualities and supplier support.

FAQ

Q: What makes certified Grade 2 titanium wire different from standard titanium wire?

A: Certified titanium wire includes comprehensive documentation verifying chemical composition, mechanical properties, and manufacturing traceability. This certification ensures compliance with international standards and provides quality assurance for critical applications. The certification process includes rigorous testing and inspection procedures that standard products may not include.

Q: How do I determine the correct wire diameter for my application?

A: Wire diameter selection depends on mechanical loading requirements, current carrying capacity, and manufacturing constraints. Our engineering team provides technical consultation to help customers select optimal specifications based on specific application requirements. Factors include tensile strength requirements, bending radius limitations, and welding compatibility.

Q: What documentation is provided with certified titanium wire shipments?

A: Complete documentation includes material test certificates showing chemical analysis and mechanical testing results, dimensional inspection reports, and manufacturing traceability records. Heat treatment documentation and surface finish verification are included where applicable. This documentation supports customer quality management and regulatory compliance requirements.

Q: Can Grade 2 titanium wire be welded to other materials?

A: Titanium wire can be welded to other titanium grades and certain compatible materials using appropriate procedures and filler metals. Dissimilar metal welding requires careful consideration of galvanic compatibility and thermal expansion differences. Our technical team provides welding procedure recommendations for specific material combinations.

Q: What are the typical lead times for custom titanium wire specifications?

A: Standard specifications are typically available within 4-6 weeks from order confirmation. Custom diameters, special surface finishes, or unique length requirements may require 6-8 weeks depending on processing complexity. Rush orders can often be accommodated through expedited processing arrangements.

Q: How should titanium wire be stored to maintain quality?

A: Titanium wire should be stored in clean, dry environments away from contaminating materials such as carbon steel or chloride-containing substances. Original packaging should be maintained until use to protect surface quality. Proper handling procedures prevent damage and contamination that could affect welding or forming operations.

Partner with Chuanghui Daye for Your Titanium Wire Requirements

Procurement professionals seeking reliable Grade 2 Titanium Wire supplier partnerships will find comprehensive solutions through Shaanxi Chuanghui Daye Metal Material Co., Ltd. Our three decades of rare metal expertise, combined with ISO 9001:2015 certified quality management systems, ensures consistent product quality and supply reliability. Technical support services include application engineering, welding procedure development, and custom specification consultation to optimize your manufacturing processes. Contact our engineering team at info@chdymetal.com for detailed quotations, technical specifications, and sample requests tailored to your specific industrial requirements.

References

1. Boyer, R., Welsch, G., & Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International, Materials Park, Ohio.

2. Donachie, Matthew J. "Titanium: A Technical Guide, Second Edition." ASM International, Materials Information Society.

3. Lutjering, G. & Williams, J.C. "Titanium: Engineering Materials and Processes." Springer-Verlag Berlin Heidelberg.

4. Schutz, R.W. & Thomas, D.E. "Corrosion of Titanium and Titanium Alloys." ASM Handbook Volume 13A: Corrosion Fundamentals, Testing, and Protection.

5. Welsch, G., Boyer, R., & Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International Handbook Committee.

6. Zwicker, U. "Titan und Titanlegierungen." Springer-Verlag Berlin Heidelberg, Materials Science and Engineering Series.

Learn about our latest products and discounts through SMS or email