- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Custom Titanium Wire for Anodizing – Fast Quote Today

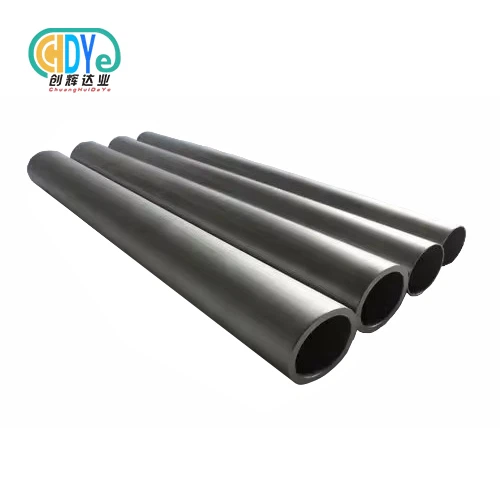

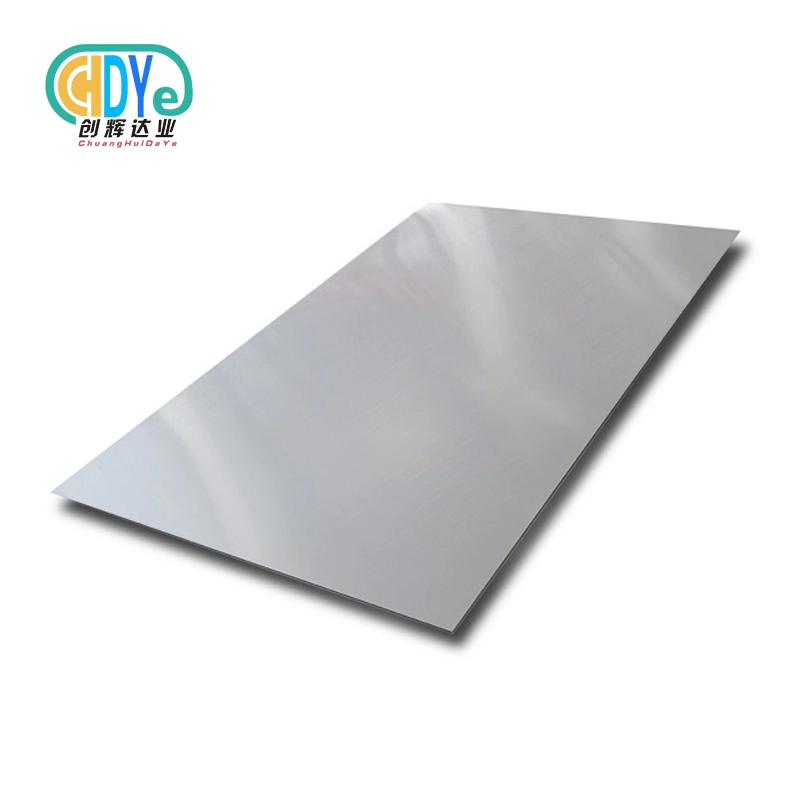

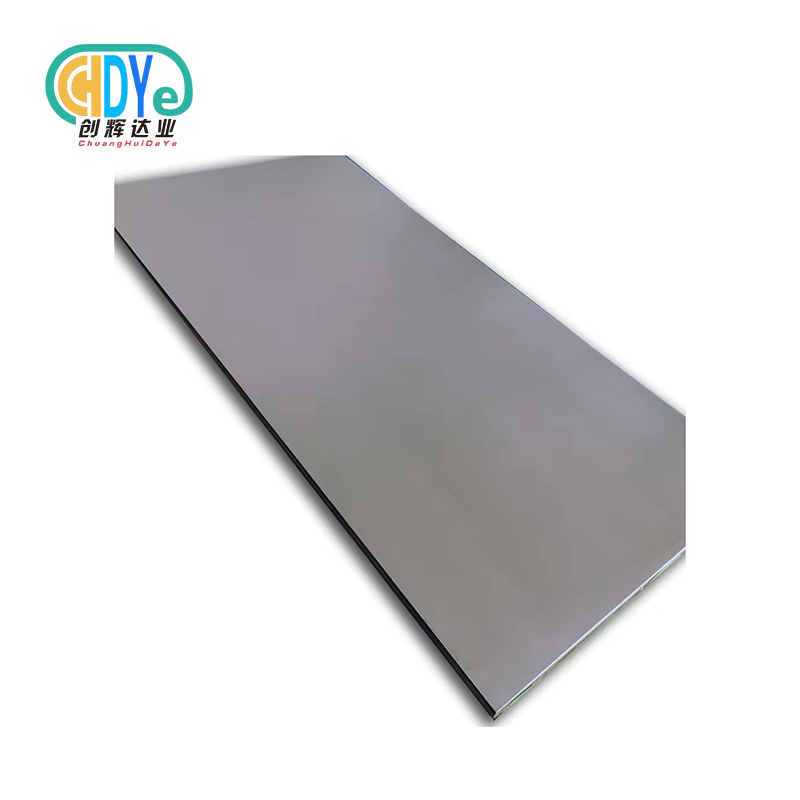

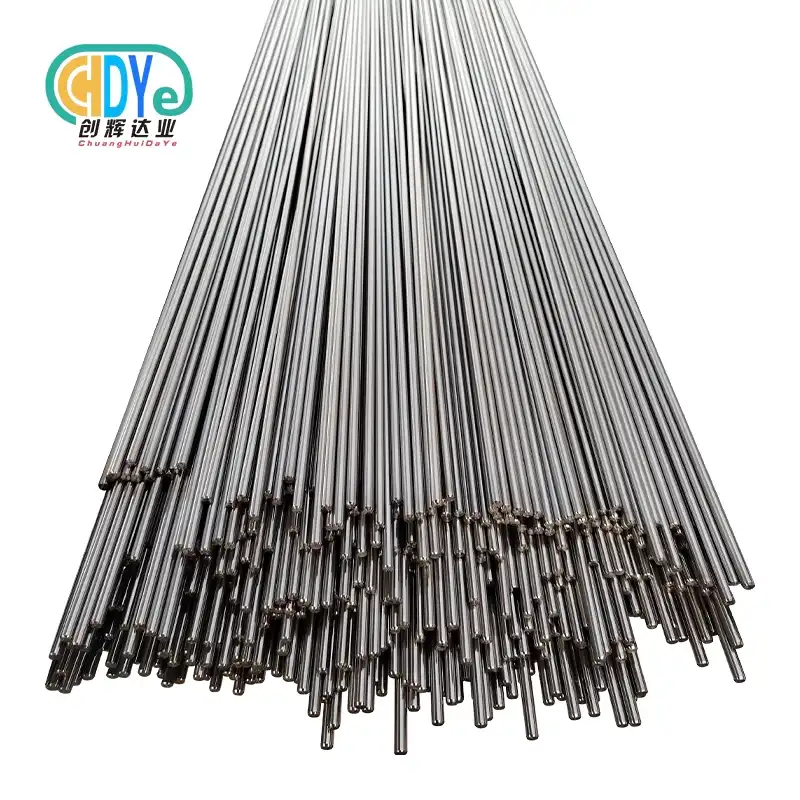

Titanium wire for anodizing is a stable and high-performance material for numerous sectors. Our premium titanium wire is suited for electrochemical applications due to its corrosion resistance and electrical conductivity. This lightweight, durable material performs well in harsh industrial applications with diameters from 0.2mm to 7mm. This material is durable and reliable for aerospace components, medical equipment, and specialist coatings.

Understanding Titanium Wire for Anodizing

Titanium wire is essential for anodizing due to its corrosion resistance, electrical conductivity, and durability. Titanium wire is better for anodic coatings than sheets or rods due to its current distribution and flexibility. This unique material is required for electrochemical procedures that require precision current flow and environmental resistance.

The Electrochemical Role in Anodizing Processes

Titanium wire is an anode, demonstrating its electrochemical properties during anodizing. The titanium wire helps target materials create regulated oxide layers when an electric current runs over it. This method generates protective and decorative coatings that improve performance and appearance. The wire's high conductivity allows uniform current distribution, which ensures coating quality across the workpiece.

Advantages Over Alternative Forms

Understanding these factors helps B2B procurement professionals make decisions that optimize anodizing results, coating quality, component lifespan, and reduce downtime. Wires are easier to manipulate in complex geometries and have more precise current control in specific applications than plates and rods.

Types and Specifications of Titanium Wire for Anodizing

The anodizing results in industrial applications depend on the titanium wire grade and diameter. Performance, environmental circumstances, and budget determine titanium grade selection. Each grade has mechanical and chemical qualities for specific industrial uses.

Grade Comparison and Properties

Review 2 commercially immaculate titanium speaks to the most broadly utilized choice for common anodizing applications. This review gives amazing erosion resistance and formability, advertising an ideal balance of quality and ductility. Its chemical composition incorporates negligible alloying components, making it reasonable for applications requiring tall immaculateness and steady execution. Review 2 titanium wire illustrates uncommon resistance to acidic arrangements commonly utilized in anodizing processes.

Grade 5 titanium amalgam (Ti-6Al-4V) serves applications requiring upgraded mechanical properties and predominant strength-to-weight proportions. This review contains 6% aluminum and 4% vanadium, giving expanded ductile quality and weakness resistance. The alloying components upgrade execution in high-stress situations while maintaining great erosion resistance characteristics fundamental for anodizing applications.

Diameter Selection and Current Density Considerations

Common wire distances across run from 0.2mm to 7mm, with each measure advertising particular focal points for distinctive applications. Littler distances across give higher current thickness and more exact control in fragile applications, whereas bigger breadths offer expanded current-carrying capacity for high-volume operations. These variables straightforwardly impact current thickness and coating consistency, making legitimate distance across determination significant for accomplishing craved results.

Wire frame focal points over bars and sheets ended up especially apparent in customized anodizing setups. The adaptability and ease of taking care of permit complex rack setups and advanced availability in restricted spaces. This flexibility makes a difference, as obtainment experts indicate materials that best meet their interesting prepare necessities and geometric limitations.

How to Optimize Your Anodizing Process Using Titanium Wire?

Titanium wire for anodizing is optimized by proper preparation and processing during anodizing. Following these procedures promotes consistent output, reduces material waste, and extends equipment life. Optimizing process parameters requires meticulous preparation and monitoring.

Surface Preparation and Cleaning Protocols

Titanium wire should be cleaned to remove surface impurities that could affect electrical contact and current distribution. Acid etching removes oxide layers and surface contaminants after solvent degreasing. The wire and electrical connections adhere better and conduct better during anodizing with this preparation.

Surface preparation affects anodizing quality and consistency. Clean titanium wire ensures steady electrical properties and consistent current distribution across the workpiece. This consistency is crucial in applications with tight tolerances and exact coating standards.

Process Sequencing and Parameter Control

The anodizing arrangement utilizing titanium wire requires careful consideration of current thickness, voltage, temperature, and electrolyte composition. Appropriate sequencing includes slow voltage increments to avoid arcing and guarantee an even coating arrangement. Temperature control keeps up electrolyte stability and anticipates undesirable chemical responses that seem compromise coating quality.

Practical tips for accomplishing coating thickness indeed incorporate keeping up reliable wire-to-workpiece separations, executing appropriate disturbance frameworks, and observing current conveyance designs. These components work together to make a predominant surface quality and uniform appearance over the whole coated surface.

Case Studies and Performance Optimization

Customized wire solutions handle anodizing problems in real-world applications across industries. Aerospace manufacturers use titanium wire anodizing for component identification and corrosion prevention for aesthetic and practical reasons. Medical device makers use biocompatible anodized titanium for implant applications where surface qualities affect patient outcomes.

Engineers and technical buyers can learn from these case studies to improve productivity and product performance. Material selection and process optimization lower production costs and improve product quality, as shown in the examples.

Choosing and Procuring Custom Titanium Wire for Anodizing

Successful custom titanium wire procurement requires supplier evaluation based on reliability, cost-effectiveness, and technical assistance. Supplier competencies, quality systems, and long-term relationship possibilities must be considered during selection. Smart procurement balances short-term cost with long-term value and reliability.

Supplier Evaluation Criteria

Examining vendors' certifications, quality assurance methods, and sustainability credentials assures material quality and delivery reliability. ISO 9001:2015 accreditation shows a supplier's quality management and continuous improvement commitment. End-use requirements may require AS9100 for aerospace or ISO 13485 for medical equipment.

Test facilities, traceability documentation, and statistical process control systems should be quality assurance capabilities. These features provide material uniformity and enable quick identification of manufacturing quality issues.

Cost Analysis and Budget Planning

Budgeting and long-term planning are easier with knowledge of material grade, size, and order volume cost components. Custom specification processing costs follow raw material costs. Companies with continuing needs benefit from integrated purchasing methods since larger orders qualify for volume savings.

Packaging, transportation, and sensitive application handling costs are also considered. Understanding these aspects improves project costing and identifies cost-optimization options without compromising quality.

Ordering Processes and Lead Time Management

Clear, enlightening on the requesting form, advanced, quick, exact citations and decrease the potential for detail blunders. Nitty-gritty specialized drawings, fabric determinations, and amount necessities empower providers to give exact quotes and reasonable delivery plans. Electronic communication frameworks streamline the requesting prepare and give documentation trails for quality and acquisition audits.

Responsive client benefit and adaptable coordination capabilities engage B2B directors and acquiring operators to secure custom-made arrangements quickly and unquestionably. Providers with numerous shipping alternatives and sped up handling capabilities can suit critical requirements and changing venture plans.

Company Introduction and Product Services

Shaanxi Chuanghui Daye Metal Material Co., Ltd. produces high-quality titanium wire for anodizing in many industries. Our company is located in Baoji High-tech Development Zone, Shaanxi Province, China's "Titanium Capital", with good transportation and industrial facilities for efficient operations and reasonable prices.

Manufacturing Capabilities and Quality Systems

Our broad customization allows us to meet anodizing application diameter, length, and grade requirements. Precision wire drawing machinery, controlled environment annealing furnaces, and extensive testing facilities ensure product quality. The production process includes raw material inspection and final packaging quality checks.

Quality certifications like ISO 9001:2015 Quality Management System Certification show our dedication to production process control. Our quality system includes raw material inspection, melting and forging, machining and forming, and final inspection to ensure specification compliance.

Global Supply Network and Customer Support

With established distribution channels and logistics relationships, our global supply network meets different industrial needs with reliable delivery. Strategic inventory levels and flexible production scheduling allow the organization to fulfill scheduled and urgent requests from clients across time zones.

Our fast bids, personalized support, and optimized logistics make procurement easy for small research institutions and large manufacturing companies. Technical support includes material selection, application consultation, and troubleshooting to help customers optimize anodizing results.

Chuanghui Daye, founded by a rare metal expert with over 30 years of experience, has strong professional foundations and technical expertise that make us a reliable partner for titanium wire supply for anodizing professionals worldwide.

Conclusion

Material grades, dimensional standards, and supplier capabilities must be considered when buying titanium wire for anodizing. Grade 2 commercially pure titanium is corrosion-resistant for common purposes, while Grade 5 titanium alloy is stronger for harsh situations. Technical skill is needed to choose diameters that maximize current density and coating uniformity. Effective supplier agreements include quality certifications, timely customer service, and reliable logistics to ensure material availability and performance.

FAQ

This section addresses key concerns frequently raised by procurement and engineering teams worldwide regarding titanium wire selection, customization capabilities, and delivery expectations.

Q: Why is titanium wire preferred for anodizing applications?

A: Titanium wire offers exceptional durability and current efficiency compared to alternative materials. Its superior corrosion resistance withstands aggressive electrolyte solutions without degradation, while excellent electrical conductivity ensures uniform current distribution. The material's biocompatible properties make it suitable for medical applications, and its lightweight design reduces handling costs while maintaining superior mechanical strength.

Q: Can wire dimensions be customized for specific applications?

A: Dimension customization is readily available to meet specific process requirements. Our manufacturing capabilities accommodate diameters from 0.2mm to 7mm with precise tolerance control. Custom lengths, special packaging configurations, and unique surface preparations can be provided based on application needs. Technical consultation services help determine optimal specifications for specific anodizing processes and geometric constraints.

Q: What are realistic lead times for bulk orders?

A:Lead time expectations vary based on order volume, specification complexity, and current production schedules. Standard grade materials in common diameters typically ship within 2-3 weeks for quantities up to 100 kg. Larger orders or custom specifications may require 4-6 weeks, depending on manufacturing requirements. Rush orders can often be accommodated with expedited processing for critical project deadlines.

Request Your Custom Titanium Wire Quote Today

Shaanxi Chuanghui Daye stands ready to support your anodizing projects with premium titanium wire solutions engineered for exceptional performance. Our experienced technical team provides comprehensive consultation services to ensure optimal material selection for your specific applications. Contact us at info@chdymetal.com to discuss your requirements with a trusted titanium wire for anodizing supplier who understands the critical importance of quality, reliability, and on-time delivery in today's competitive manufacturing environment.

References

1. ASM International Handbook Committee. "Properties and Selection: Nonferrous Alloys and Special-Purpose Materials." ASM Handbook Volume 2, 10th Edition, ASM International, 1990.

2. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International Materials Park, Ohio, 2000.

3. Lutjering, Gerd and James C. Williams. "Titanium, 2nd Edition: Engineering Materials and Processes." Springer-Verlag Berlin Heidelberg, 2007.

4. Boyer, Rodney, Gerhard Welsch, and E.W. Collings. "Materials Properties Handbook: Titanium Alloys." ASM International Materials Park, Ohio, 1994.

5. Rack, Henry J. and James N. Qazi. "Titanium alloys for biomedical applications." Materials Science and Engineering C, Volume 26, Issues 6-7, 2006.

6. Peters, M., J. Hemptenmacher, J. Kumpfert, and C. Leyens. "Structure and Properties of Titanium and Titanium Alloys." Titanium and Titanium Alloys: Fundamentals and Applications, Wiley-VCH, 2003.

Learn about our latest products and discounts through SMS or email