- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Grade 2 Titanium Wire with Excellent Fatigue Resistance

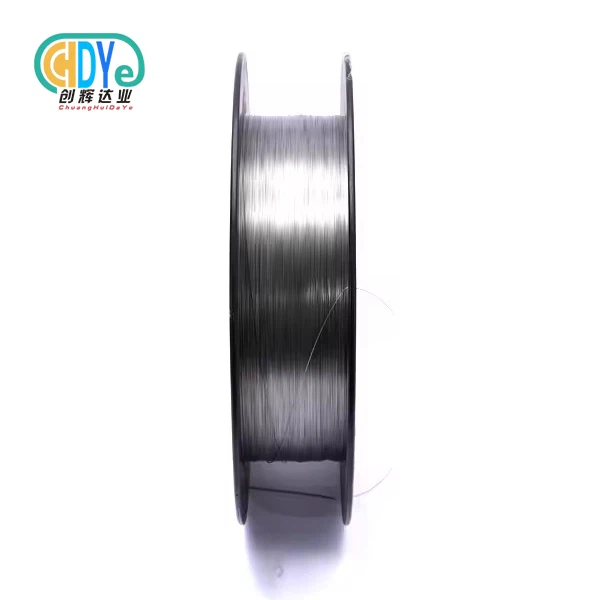

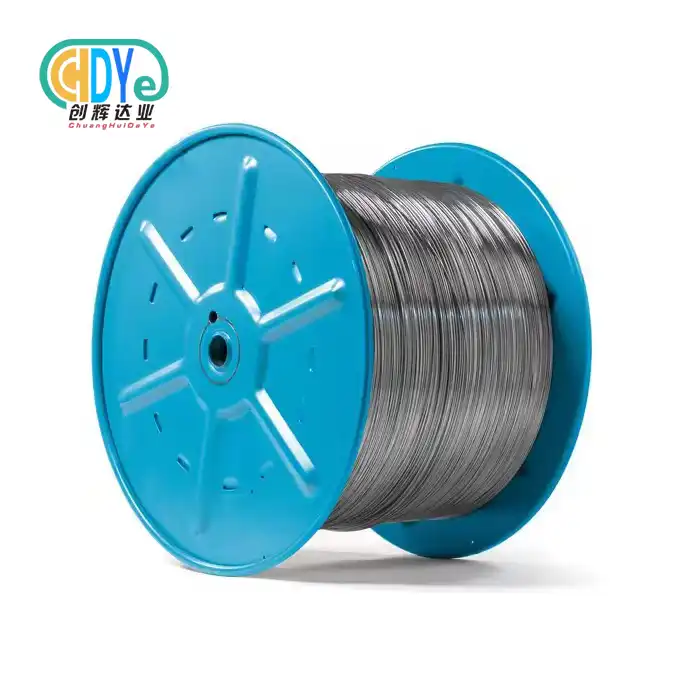

For industrial applications needing fatigue resistance and corrosion protection, Grade 2 Titanium Wire is the best. High-cyclic loading performance makes this commercially pure titanium material essential for aerospace, medicinal, and chemical processing equipment. Grade 2 Titanium Wire saves maintenance costs and extends component service life for engineers and procurement professionals due to its high strength-to-weight ratio and proven durability in harsh conditions.

Understanding Grade 2 Titanium Wire and Its Key Properties

Fundamental Mechanical Characteristics

Grade 2 titanium is the most versatile commercially pure titanium, comprising 99.2% titanium and well controlled trace elements such 0.25% iron, 0.03% carbon, 0.08% oxygen, and 0.015% nitrogen. One of the strongest commercially pure titanium grades, this exact composition has a minimum yield strength of 275 MPa and an ultimate tensile strength of 450 MPa.

The consistent grain structure and intrinsic metallurgical characteristics provide the material high fatigue resistance. Grade 2 titanium wire preserves structural integrity better than typical materials under cyclic loading, with fatigue limits approaching 50-60% of its ultimate tensile strength. This trait is essential for industrial components under repeated stress cycles.

Chemical Composition and Environmental Durability

Grade 2 titanium wire resists corrosion in many operating situations due to its chemical balance. Its passive oxide layer naturally forms when exposed to oxygen, blocking chlorides, acids, and seawater corrosion. This protective mechanism is stable at 315°C, making the material acceptable for severe chemical processing.

Processing improves wire performance. Complex forming without fatigue resistance is possible with 600°C annealing, which removes strain hardening and improves ductility. Applications requiring efficient heat transmission benefit from the material's 16.4 W/m-K thermal conductivity at room temperature.

Standards Compliance and Quality Assurance

Grade 2 titanium wire from certified sources satisfies ASTM B348 and ISO 5832 requirements. These standards maintain mechanical qualities, dimensional tolerance, and surface quality across production batches. Material traceability paperwork includes chemical and mechanical test reports for quality verification for each shipment.

Comparing Grade 2 Titanium Wire with Other Materials and Grades

Titanium Grade Variations and Performance Differences

When assessing titanium wire alternatives, understanding the refinements between different grades gets to be fundamental for ideal fabric determination. Review 2 offers predominant formability compared to Review 4, which contains higher oxygen substance coming about in expanded quality but decreased ductility. Review 5 (Ti-6Al-4V), whereas giving higher quality characteristics, requires more complex preparing and carries altogether higher fabric costs.

The following comparison highlights key performance differences:

• Grade 2: Excellent formability, moderate strength (450 MPa UTS), outstanding corrosion resistance, ideal for complex geometries

• Grade 4: Higher strength (550 MPa UTS), reduced formability, similar corrosion resistance, suitable for structural applications

• Grade 5: Highest strength (895 MPa UTS), limited formability, requires specialized welding procedures, aerospace applications

These distinctions guide procurement decisions based on specific application requirements, balancing performance needs against processing complexity and material costs.

Material Alternatives and Cost-Benefit Analysis

Comparing Review 2 titanium wire with elective materials uncovers compelling points of interest that frequently legitimize higher beginning costs. Stainless steel 316L, whereas less costly forthright, shows second rate erosion resistance in chloride situations and has about twice the thickness of titanium. This weight punishment deciphers into expanded basic loads and diminished fuel proficiency in transportation applications.

Aluminum combinations offer lightweight characteristics but need the erosion resistance and high-temperature steadiness of titanium. In marine situations, aluminum encounters galvanic erosion when coupled with disparate metals, constraining its application scope. Review 2 titanium wire kills these concerns whereas giving amplified benefit life that decreases add up to proprietorship costs over the component lifecycle.

Medical and Industrial Grade Distinctions

Correctly selecting medical-grade and industrial-grade titanium wire for certain purposes requires knowledge of their distinctions. Medical-grade variations are purified further to ensure biocompatibility, with stronger trace element and surface contamination restrictions. Industrial applications permit wider specification ranges while meeting mechanical performance criteria.

Applications and Advantages of Grade 2 Titanium Wire with Excellent Fatigue Resistance

Industry-Specific Applications and Performance Benefits

In aircraft applications where fatigue resistance affects component durability, Grade 2 titanium wire is crucial. It can resist millions of stress cycles, making it ideal for aircraft engine parts, hydraulic system fittings, and structural fasteners. The high strength-to-weight ratio boosts fuel efficiency and cuts maintenance.

Chemical processing plants use Grade 2 titanium wire for heat exchangers, valve stems, and corrosion-resistant fasteners. The material's chloride stress corrosion cracking resistance makes it durable in severe chemical situations where stainless steel would fail quickly. Saltwater corrosion resistance benefits offshore oil platforms.

Medical device makers use Grade 2 titanium wire in surgical, dental, and implantable devices. The material's biocompatibility prevents tissue responses and provides mechanical strength for long-term implant success. Orthodontics use the wire's formability and corrosion resistance for patient safety.

Operational Advantages and Economic Impact

Its fatigue resistance gives Grade 2 titanium wire operational advantages that lower total ownership costs. This material reduces replacement frequency and downtime costs by providing 2-3 times longer service lives than conventional alternatives. Maintenance schedules can be extended, boosting efficiency.

Here are the core operational benefits that make Grade 2 titanium wire economically attractive:

• Extended service life: Components last 2-3 times longer than steel alternatives, reducing replacement costs

• Reduced maintenance frequency: Corrosion resistance eliminates routine inspection and replacement cycles

• Weight savings: 45% lighter than steel, reducing structural loads and improving fuel efficiency

• Temperature stability: Maintains properties from cryogenic temperatures to 315°C operating range

These advantages create compelling value propositions for industries where reliability and lifecycle costs drive material selection decisions.

Processing Best Practices and Quality Preservation

Best practices must be followed to maintain Grade 2 titanium wire's fatigue resistance throughout manufacture. Inert gas shielding and backing gas protection avoid contamination during welding with complete atmospheric exclusion. During welding, oxygen, nitrogen, and hydrogen contamination can drastically degrade fatigue performance.

Avoid excessive cold labor that causes residual strains during forming. After cold forming, stress relief annealing at 480-650°C optimizes mechanical characteristics. Scratches or tool marks can cause fatigue cracks under cyclic loads, therefore surface preparation is crucial.

Procurement Guide: How to Buy Grade 2 Titanium Wire Effectively?

Quality Verification and Standards Compliance

Material compliance with requirements is essential for Grade 2 titanium wire procurement. ASTM B348 and ISO 5832 specify chemical composition limitations, mechanical properties, and dimensional tolerances for material performance. Each shipment should include a certificate of compliance with chemical and mechanical test results.

When buying important commodities, supplier certification is crucial. ISO 9001:2015 accreditation shows quality management system commitment, while AS9100 for aerospace applications adds assurance. Regulatory businesses can document quality from raw material source to final processing with material traceability.

Volume Pricing Strategies and Supply Chain Considerations

Understanding pricing dynamics optimizes procurement costs and supply reliability. Raw material costs, manufacturing complexity, and order volumes affect grade 2 titanium wire pricing. Bulk purchasing agreements save money, especially for conventional sizes.

Determine supplier capacity, location, and backup sourcing options for supply chain resilience. Titanium production is regional, making supply chain diversification crucial for vital applications. Project schedules require earlier planning due to lead periods of 4-12 weeks depending on specification complexity and order quantity.

Custom Specifications and Technical Support

Many applications demand wire dimensions outside typical ranges. Qualified providers offer 0.2mm to 8.0mm diameters with pickled or bright annealed finishes. Custom packaging meets handling or automated feeding needs.

Technical support distinguishes premium suppliers from commodities. Application engineering aids material selection, while processing advice ensures manufacturing success. Post-sales support includes application feedback-based troubleshooting and performance optimization.

Company Introduction and Product & Service Information

Manufacturing Excellence in China's Titanium Capital

China's "Titanium Capital." Baoji High-tech Development Zone houses Shaanxi Chuanghui Daye Metal Material Co., Ltd. The strategic location offers excellent metallurgical facilities and technical expertise from decades of titanium manufacturing excellence. Excellent transportation networks and supply chains provide reliable material sourcing and efficient distribution at our facilities.

An industry veteran with over 30 years of rare metal experience founded our company, which blends metallurgical knowledge with modern production. We produce Grade 2 titanium wire that satisfies international quality standards at competitive prices for worldwide markets thanks to our expertise. Our quality-first approach improves product reliability and customer happiness via continual improvement.

Comprehensive Product Range and Processing Capabilities

We manufacture titanium wire in all sizes, from 0.2mm precision wire for electronics to 8.0mm structural wire for heavy industrial. Modern processing equipment includes electron beam furnaces for material purity, precision rolling mills for dimension accuracy, and controlled environment annealing systems for mechanical attributes.

We use quality control systems throughout our operation to assure material performance throughout product standards. In-process monitoring maintains dimensional tolerances and surface quality, while raw material inspection checks chemical composition and purity. Before packaging and shipping, mechanical testing, dimensions verification, and surface quality assessment are performed.

Technical Support and Customer Service Excellence

Our expert staff helps customers optimize material selection and processing parameters with extensive application assistance. This involves welding method development, forming operation guidance, and performance troubleshooting. Integrating customer feedback drives product development to meet industry needs.

Quick order processing, versatile packaging for different handling systems, and regulatory compliance documents are customer service skills. Our transparency includes complete material certifications and traceability paperwork that fulfills the highest quality standards.

Conclusion

Grade 2 Titanium Wire with outstanding fatigue resistance is a premium material for industrial applications that require durability and performance. Its corrosion resistance, mechanical strength, and lightweight make it valuable in aircraft, medical, chemical processing, and electronics. The material's cyclic loading performance and environmental endurance make it a crucial component for critical systems that need long service life and little maintenance.

FAQ

Q: What distinguishes Grade 2 from Grade 5 titanium wire in fatigue applications?

A: Grade 2 titanium wire offers superior formability and weldability compared to Grade 5, making it ideal for complex geometries and precision fabrication. While Grade 5 provides higher ultimate strength, Grade 2 delivers excellent fatigue resistance with easier processing requirements and lower material costs. Grade 2 maintains consistent mechanical properties through a wider range of operating temperatures, making it more versatile for diverse applications.

Q: How does Grade 2 titanium wire perform in aggressive chemical environments?

A: Grade 2 titanium wire exhibits exceptional resistance to chloride environments, acids, and alkaline solutions due to its stable passive oxide layer. This natural protection mechanism resists pitting corrosion and stress corrosion cracking that commonly affect stainless steel materials. The material maintains integrity in seawater applications and chemical processing environments where other materials experience rapid degradation.

Q: What welding considerations maintain fatigue resistance in Grade 2 titanium wire?

A: Maintaining fatigue resistance during welding requires complete atmospheric protection using argon or helium shielding gas with backing gas protection. Contamination from oxygen, nitrogen, or hydrogen significantly reduces fatigue performance. Proper joint design, controlled heat input, and post-weld stress relief when necessary preserve the material's excellent fatigue characteristics throughout the fabrication process.

Partner with Chuanghui Daye for Premium Grade 2 Titanium Wire Solutions

Shaanxi Chuanghui Daye combines three decades of metallurgical expertise with state-of-the-art manufacturing capabilities to deliver Grade 2 Titanium Wire that exceeds industry standards. Our ISO 9001:2015 certified facility ensures consistent quality and reliable supply chains for global customers requiring materials with excellent fatigue resistance. Contact our technical team at info@chdymetal.com to discuss your specific requirements and receive detailed quotations from a trusted Grade 2 Titanium Wire supplier committed to your project success.

References

1. Boyer, R., Welsch, G., & Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International Materials Park, 2007.

2. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International Technical Publications, 2000.

3.Lutjering, G. & Williams, J.C. "Titanium Engineering Materials and Processes." Springer-Verlag Berlin Heidelberg, 2003.

4. Schutz, R.W. & Thomas, D.E. "Corrosion of Titanium and Titanium Alloys in Industrial Applications." Metals Handbook Corrosion Volume 13, ASM International, 1987.

5. ASTM International. "Standard Specification for Titanium and Titanium Alloy Bars and Billets - ASTM B348." ASTM Standards Publication, 2019.

6. Peters, M., Hemptenmacher, J., Kumpfert, J. & Leyens, C. "Structure and Properties of Titanium and Titanium Alloys for Aerospace Applications." Titanium and Titanium Alloys: Fundamentals and Applications, Wiley-VCH, 2005.

Learn about our latest products and discounts through SMS or email