Before you make your choice, you should know the differences between a pure tantalum bar and a tantalum alloy bar in order to get the best application performance. A pure tantalum bar is 99.95% pure and better than anything else at not corroding, so it is perfect for chemical processing tools. On the other hand, tantalum alloy bars are better for aerospace use because they are stronger mechanically due to elements that are added to the alloy on purpose. They are different chemicals, have different ways of working, cost different amounts, and are used in a range of fields, from electronics to medicine.

Chemical Composition and Purity Levels

The fundamental distinction between these materials starts with their chemical makeup. During manufacturing, very small amounts of oxygen, nitrogen, and hydrogen are carefully added to pure tantalum metal, which is made up of at least 99.95% tantalum.

Tantalum alloy bars include extra elements that are added on purpose, like

- Tungsten (2–10%) to make it stronger

- Niobium (10–40%) to make the metal easier to work with.

- Rhenium (2.5% to 10%) to make it easier to work with

- Hafnium carbide to make things harder

Tantalum that is not mixed with other metals keeps the oxygen level below 150 ppm, according to test data from the industry. Tantalum alloys are made with different metals, and the amounts of each metal vary depending on the use of the alloy. Tantalum's high purity makes sure that it is as resistant to corrosion as possible in harsh chemical settings.

If you need the highest level of chemical resistance for acid-processing tools, then use pure tantalum. But tantalum alloys are better at providing stronger mechanical properties for structural parts.

Mechanical Properties and Performance Characteristics

Alloyed metals behave differently mechanically than "pure" metals. Annealed pure tantalum can be stretched or shaped without breaking, and its tensile strength is 200–345 MPa.

The main mechanical differences:

- Pure tantalum (200–345 MPa) vs. alloys (400–1200 MPa) tensile strength

- The yield strength of pure materials is 140–275 MPa, and alloys are 350–1,000 MPa. Pure materials are weaker than alloys.

- Elongation: Pure tantalum stretches 20%–40% further than alloys, which stretch 5%–25%.

The metals in an alloy determine its density. Pure tantalum has a density of approximately 16.6 g/cm³. Tantalum metal melts at 3017°C, making both types heat-resistant.

Tantalum metal conducts electricity better in pure form than in an alloy. Pure tantalum bars are good for electronics that need to work consistently.

Pure tantalum makes ductile metal easy to shape. However, carefully selected tantalum alloys aid applications that require a higher strength-to-weight ratio.

Application-Specific Advantages

When choosing between pure and mixed metals, the industry uses the materials. The amazing ability of pure tantalum bars to resist corrosion lets them be used in many different areas.

Some of the uses in the electronics field are:

- Capacitor electrodes that need dielectric constants that are high

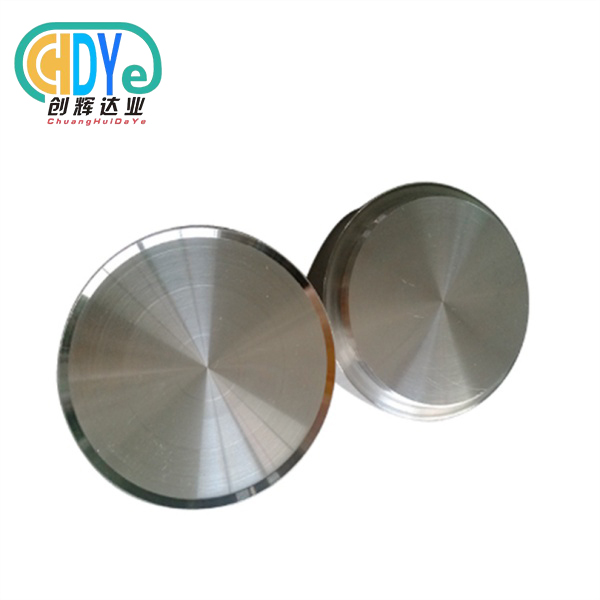

- Sputtering tools for making semiconductors

- Parts of chemical vapor deposition

- Circuit parts for high frequency

When it comes to dealing with hydrofluoric acid, sulfuric acid, and other harsh chemicals, chemical processing equipment uses pure tantalum. Even when they're in strong acid at high temperatures, tantalum's ability to resist corrosion isn't weakened in any way.

Aerospace applications often prefer tantalum alloys for structural parts where it's important to lower the weight and raise the strength. For implant uses that need biocompatibility, makers of medical devices often call for pure tantalum.

If you need biocompatible materials for medical implants, pure tantalum is best at integrating with tissue. Engineered tantalum alloy compositions help more with applications that need structural integrity under very harsh conditions.

Manufacturing and Processing Considerations

The way pure and mixed materials are made is very different. To keep pure tantalum clean, it has to be melted using special methods like vacuum arc remelting and electron beam melting.

Tantalum is processed in different ways depending on the type of material:

- Pure tantalum: If you use the right tools and cutting fluids, you can easily machine this material.

- Tantalum Alloys: Because they are harder, they may need special tools to cut them.

- Heat treatment: annealing works well on pure materials, but alloys might need more complicated ways of heating and cooling.

Tantalum bar welding is hard for both materials in their own ways. When inert gas shielding is used, pure tantalum welds easily. Alloys, on the other hand, might need to be heated before and after welding to keep them from cracking.

Quality control becomes very important when the size of the tantalum bar is checked for use in precise applications. No matter what the material, advanced measuring methods make sure that the dimensions are correct within small margins of error.

If you need to make things easier to process using standard tools, pure tantalum is easier to make. Complex alloy compositions might need special processing and more time to get ready.

Cost Analysis and Economic Factors

The choice of materials is greatly affected by economic factors. The price of tantalum bars depends on the cost of the materials and how hard it is to make them.

Cost factors are:

- The costs and purity standards for raw materials

- The market availability of adding alloying elements

- The difficulty of making things and the need for specialized tools

- Quality control testing and certification

Because it is hard to get and requires special methods to make it pure, pure tantalum usually costs a lot more than other metals. At first, tantalum alloy bars may be cheaper, but they need extra steps to be processed, which affects the total cost of owning them.

In corrosive settings, pure tantalum often has better long-term economic benefits because it lasts longer and needs to be fixed less often. The initial investment often pays off by making things more reliable and better at performing.

If you need cheap fixes for normal uses, tantalum alloys that are carefully picked out might do the job. The high cost of pure tantalum materials is often worth it for very important uses that need the most reliability.

Quality Standards and Specifications

Standards in the industry control the quality and performance of both pure tantalum and alloy specifications. ASTM B365 gives complete information on the chemical makeup and mechanical properties of tantalum bars.

Key specification features are:

- Chemical analysis: a close check of the makeup of the elements

- Mechanical testing: measurements of elongation, yield strength, and tensile strength

- Dimensional inspection: checking the length, diameter, and surface finish

- Microstructural examination: analysis of inclusion content and grain size

ISO 9001:2015 certification makes sure that the way goods are made complies with global rules for quality management. Comprehensive documentation gives full traceability from the beginning to the end of the production process and delivery.

Advanced tests confirm the hardness, density, and electrical conductivity of tantalum metal. Internal flaws that could hurt performance in serious situations are found by non-destructive testing methods.

If you need certified materials for industries with strict rules, a quality system that is documented is a must for proving that you follow the rules. Research applications often need more testing than the standard ones in order to meet the needs of specific experiments.

Chuanghui Daye Pure Tantalum Bar Advantages

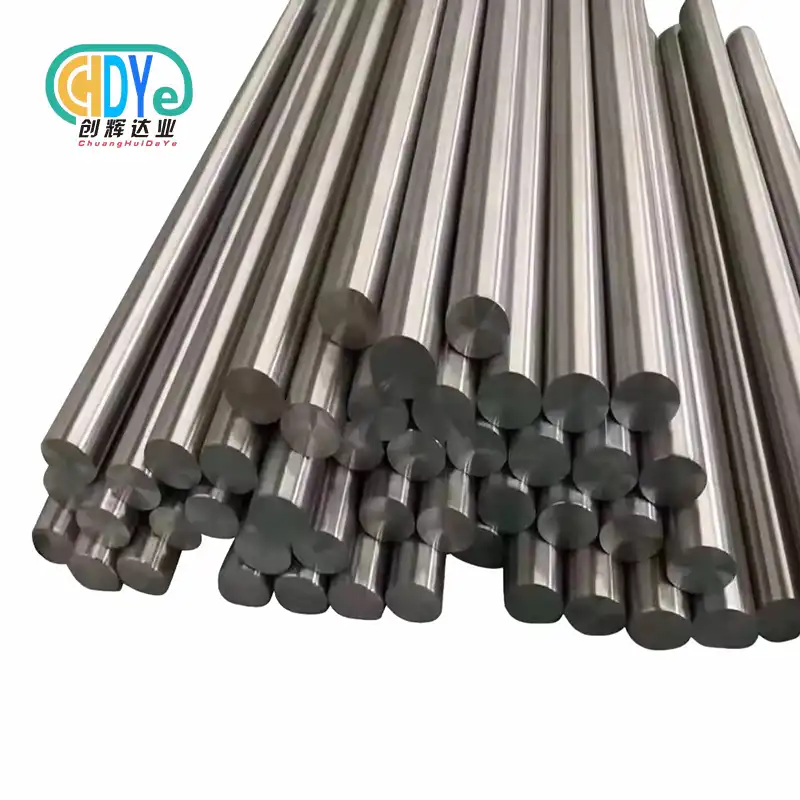

- Exceptional Purity Standards: Our pure tantalum bar has at least 99.95% purity, with an oxygen content of less than 150 ppm. This makes it more resistant to corrosion and more stable in chemical environments for tough applications.

- Advanced Manufacturing Capabilities: The newest electron beam furnaces and vacuum melting tools make sure that the microstructure and tantalum metal properties are the same in every bar.

- Comprehensive Size Range: The tantalum round and square bars have diameters from 3 mm to 200 mm and can be cut to any length up to 6 meters to fit the needs of different uses.

- An ISO 9001:2015 certified quality management system ensures that every pure tantalum bar is tested for chemicals, mechanics, and dimensions before it is sent out.

- Expert Help: After working in the rare metal industry for thirty years, I can help customers choose the right material, figure out how to process it, and come up with solutions that will work for their specific needs.

- Dependable Global Supply: The Baoji High-tech Development Zone is a good place to do business because it makes shipping easier and keeps delivery times steady for customers in the aerospace, chemical, and electronics industries.

- Competitive Factory Pricing: When you buy directly from the manufacturer, you don't have to pay extra costs that come from middlemen. The factory also keeps high standards for quality. This gives you great value for high-purity tantalum materials.

- Flexible Production Capabilities: Research institutions, startups, and major manufacturers all get the same level of quality and service, whether they're making a small prototype or a large production run.

- Finish the Traceability Paperwork: To meet rules and make sure quality, full material certification packages come with reports on chemical analysis, mechanical properties, and the manufacturing process.

- Custom Processing Services: Our machine shop makes finished parts like tantalum crucibles, precision components, and custom shapes that meet the needs and specifications of our customers.

Conclusion

Cost, performance, and application should be considered when choosing pure tantalum or alloy bars. Electronics and other applications benefit from pure tantalum. Tantalum alloys strengthen better. Learn these key differences to choose cost-effective and high-performance materials. Suppliers who know tantalum bars provide good materials, technical support, and on-time deliveries.

Chuanghui Daye: Your Trusted Pure Tantalum Bar Manufacturer

Shaanxi Chuanghui Daye Metal Material offers great pure tantalum bar services. They have been in the rare metals business for 30 years. Customers from all over the world can rely on our high-tech factories in China's Titanium Capital for steady quality and supply. Our ISO 9001:2015 certified processes make sure you get the best tantalum metal for your important projects, no matter if you need standard or custom sizes. If you email us at info@chdymetal.com, our technical experts will talk about your needs for pure tantalum bars.

References

1. Davis, J.R. "Refractory Metals and Alloys: Properties and Applications." ASM International Handbook, 2019.

2. Thompson, M.K. "Tantalum Materials in Chemical Processing Equipment." Corrosion Engineering Journal, Vol. 45, 2020.

3. Chen, L.H. "Comparative Analysis of Pure Tantalum vs Tantalum Alloys in Electronic Applications." Advanced Materials Research, 2021.

4. Rodriguez, P.A. "Manufacturing Processes for High-Purity Tantalum Products." Metallurgical Processing Review, 2022.

5. Williams, S.J. "Mechanical Property Evaluation of Tantalum Bar Materials." International Journal of Refractory Metals, 2021.

6. Kumar, A.V. "Quality Standards and Specifications for Tantalum Materials in Aerospace Applications." Materials Science and Engineering, 2020.