To find a high-quality tantalum alloy plate online, you need to carefully think about the specs, the supplier's reputation, and the needs of the application. This complete guide walks you through important issues like material grades, certification standards, quality testing methods, and criteria for judging a supplier. Whether you need a tantalum metal plate for semiconductors, aerospace parts, or chemical processing equipment, knowing these important buying factors will help you make smart purchases and build strong supply partnerships that meet the exact performance and delivery needs of your project.

Understanding Tantalum Alloy Properties and Benefits

Sheet materials made of tantalum metal have great performance qualities that make them useful in many fields. The composition of the high-strength tantalum alloy makes it very resistant to corrosion, even in harsh chemical conditions. These materials keep their shape at temperatures above 3000°C, which makes them necessary for high-temperature uses in defense and aircraft manufacturing.

Extremely strong acids, such as hydrochloric, sulfuric, and nitric acid solutions, can't damage the tantalum metal. Chemical and petrochemical equipment makers need materials that are reliable for tanks, pipes, and heat exchangers, and this feature is very important. Additionally, the biocompatibility of tantalum alloys makes them good for making medical devices, especially implants and surgical tools.

Tantalum alloy's high density helps it have great mechanical qualities while still being easy to work with. Electronics and semiconductor businesses that need precise performance in vacuum settings can benefit from the material's ability to conduct electricity and stay stable at high temperatures. Knowing these basic features of tantalum alloys helps buyers choose the right grades for different uses.

Key Specifications and Grade Selection

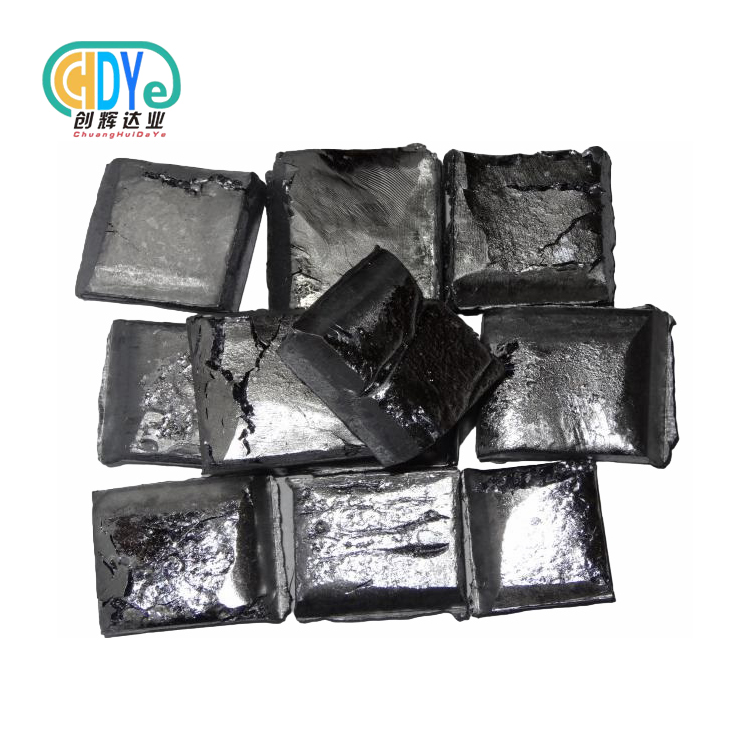

To choose the right tantalum alloy plates, you need to know about the different grades and what they are meant to do. Standard grades in the industry are R05200, R05240, R0525, and R05255. Each has a different chemical makeup of tantalum alloy. These grades meet the requirements of ASTM B708, which guarantees consistent quality and efficiency.

R05200 is commercially pure tantalum that is very easy to shape and doesn't rust. R05240 has tungsten added to it, which makes it stronger while keeping its fabrication qualities the same. Specific alloying elements are added to the R0525 and R05255 grades to make tantalum alloys stronger and better at working at high temperatures.

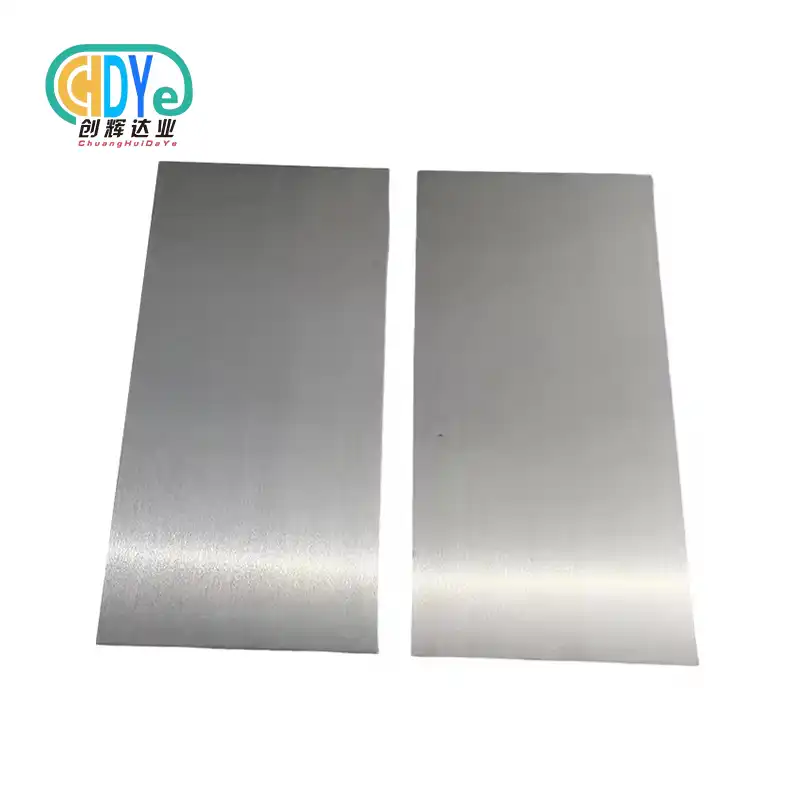

The thickness is usually between 0.5 and 20 mm, the width is between 50 and 1200 mm, and the length is between 30 and 2500 mm. These different sizes meet the needs of a wide range of applications in the electronics, chemical processing, and aircraft industries. Specialized tantalum alloy supplier agreements can often make custom sizes possible.

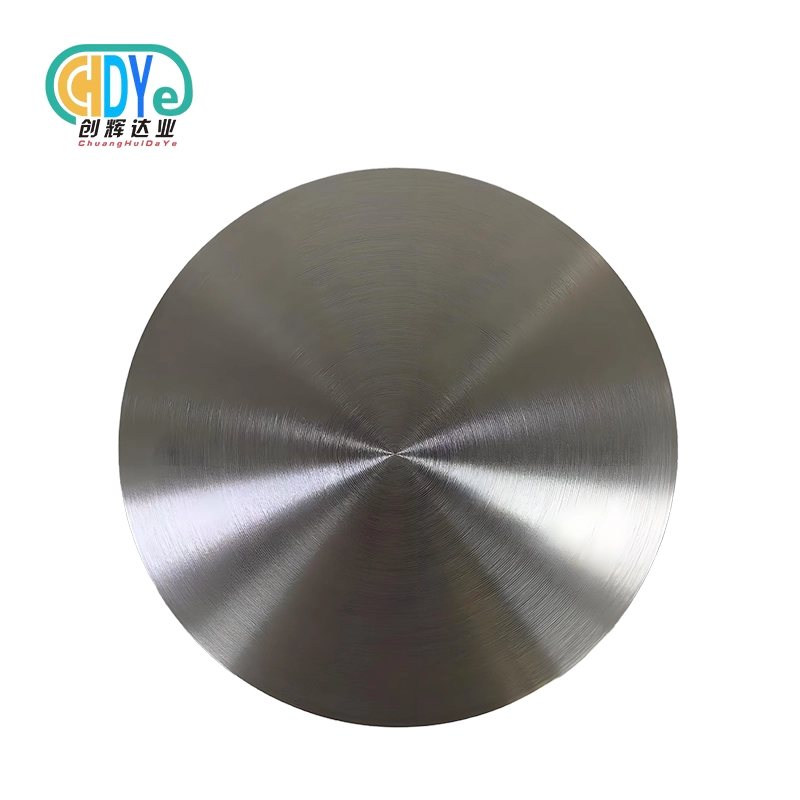

The need for surface finish depends on the purpose. For semiconductor uses, some projects need surfaces that are mirror-polished, while for structural parts, others need finishes that are milled to a standard size. Knowing these small details about specifications helps buyers clearly state their exact needs.

Evaluating Supplier Quality and Certifications

To make tantalum alloys reliably, you need suppliers with quality management methods that have been shown to work. Getting ISO 9001:2015 approval shows that you are committed to maintaining quality throughout the whole production process. This certification makes sure that sellers follow the right standards for inspecting raw materials, melting and forging, machining, and final inspection.

The ability to manufacture has a direct effect on the quality of the product and the time it takes to deliver. Vacuum electron beam melting equipment, precision rolling machines, and controlled atmosphere annealing ovens should all be part of advanced facilities. These technologies make sure that the material is pure and that the microstructure develops evenly during the heat treatment methods for tantalum alloys.

Traceability documentation is an important part of making sure that vital applications are of high quality. Full material certificates should have records of processing parameters, chemical composition analysis, and mechanical testing data. This paperwork is especially useful for aerospace and medical gadget uses that need to know the full history of a material.

Buying decisions are greatly improved by suppliers who have experience in certain businesses. Companies with a lot of experience in the aerospace, chemical processing, or technology industries know how to meet the specific needs of certain applications and deal with any problems that might come up. This knowledge means better technical help and the ability to solve problems.

Cost Factors and Pricing Considerations

Price models for tantalum alloy are based on a number of factors, such as the cost of the raw materials, the difficulty of the processing, and the number of orders. Realistically, setting budget goals and looking for ways to cut costs are easier when buyers understand these factors. Due to limited global supply sources, market factors have a big effect on the price of raw tantalum.

Processing needs affect how prices are set in the end. Standard-width plates usually cost less than custom-rolled materials that need to be handled in a certain way. Tantalum alloy machining services add worth to a project, but they also raise the cost of the whole thing. When processing parts with complex shapes or tight tolerances, more time and special tools are needed.

Through economies of scale, the number of units ordered affects the price per unit. Larger orders often get discounts for buying in bulk, while small study quantities may have higher prices. But different providers have very different minimum order requirements, which makes it harder to get what you need for prototype development.

For foreign orders, shipping, handling, and customs duties cost extra. These things can add up to big chunks of the total cost of a project, especially for quick orders that need fast shipping methods. These extra costs can be kept to a minimum by planning ahead.

Applications Across Industries

For aerospace uses, tantalum alloy takes advantage of the material's ability to stay stable at high temperatures and prevent corrosion. Tantalum works very well in harsh situations and is used in parts of airplane engines, spacecraft heat shields, and satellite structures. Because the material is strong for how light it is, it is useful for aerospace uses that need to save weight.

Tantalum alloys are used in the chemical and petrochemical industries because they are resistant to wear in harsh processing conditions. Tantalum's chemical inertness is important for keeping reactor tanks, distillation columns, and heat exchanger parts working well. For high-pressure uses, the material's ability to prevent stress corrosion cracking is very important.

The electrical qualities and purity levels of tantalum are important for making electronics and semiconductors. Specific electrical conductivity properties of tantalum alloy are needed for sputtering targets, crucibles, and vacuum chamber parts. Because the material has a low gas pressure, it works well in high-vacuum situations.

Manufacturers of medical devices like it when internal devices are made of tantalum alloy because it is biocompatible. Tantalum is non-reactive and works well with tissue, which makes it useful for orthopedic implants, dental applications, and surgical tools. The radiopacity of the material helps with medical images.

Quality Testing and Inspection Requirements

Full quality checks make sure that tantalum metal plate products meet the needs of the application. Spectroscopic methods are used in chemical composition research to check the amount of alloy and impurities present. These tests make sure that the grades are met and look for possible contamination problems.

Tensile strength, yield strength, and elongation properties are all checked by mechanical tests. These factors have a direct effect on how well a material works when it is put under operational stresses. For uses that involve changing loads, impact testing may be needed.

Dimensional checking checks the quality of the edges, flatness tolerances, and the uniformity of the thickness. Tight dimensional controls are needed for precision uses to make sure they fit and work right. Measuring the surface finish confirms the roughness needs for certain uses.

Ultrasonic screening and dye penetrant testing are two examples of non-destructive testing methods that can find problems inside or on the surface. These inspection methods are necessary for important tasks where the purity of the material cannot be compromised.

Fabrication and Customization Services

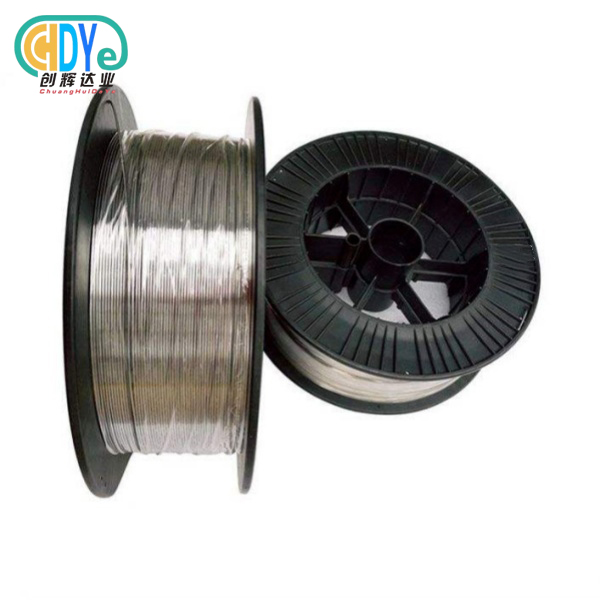

Welding of tantalum alloy plates makes it possible to make unique parts with complicated shapes. Specialized welding methods keep the qualities of the material while making strong connections between parts that have been put together. The right way to weld keeps the joint clean and prevents contamination.

Machining services take normal plate materials and turn them into precise parts. Computer-controlled machining centers can make parts with complicated shapes and tight tolerances. Knowing how to machine tantalum alloys helps you choose the best cutting settings and tools.

Custom forming services use controlled deformation methods to make parts that are curved or shaped. Hot forming keeps the material's flexibility while shaping it into the desired shape that is wanted. Cold forming can be used for easy bends, but it's important to be aware of the limits of the material.

Polishing, etching, and sealing are all types of surface treatments. These services improve the look, the qualities, or the readiness of surfaces for further processing. For gluing or plating, the right way to prepare the surface is very important.

Delivery and Logistics Considerations

Knowing when things need to be delivered helps you make good plans for job schedules. Stock materials usually ship between one and three days, while special production takes about fifteen business days. Orders that need to be processed quickly may be able to be processed.

The rules for packaging keep things safe while they're being shipped and handled. Using the right wrapping keeps surfaces from getting damaged, contaminated, or deformed while they're being shipped. For precision-machined parts or big plates, you may need to use different packaging.

When you ship something internationally, you may have to deal with customs paperwork and delays. Problems are less likely to happen when you work with experienced sellers who know how to handle exports. Clearing customs goes smoothly when the right paperwork and categories are used.

Carrying costs and supply security are both taken into account in inventory management methods. Just-in-time delivery keeps production plans while reducing the amount of inventory that needs to be kept. Having a buffer stock protects you against sudden changes in demand or problems with supply.

Conclusion

Successfully purchasing a tantalum alloy plate online requires understanding material properties, specifications, supplier qualifications, and application requirements. Quality certifications, comprehensive testing, and reliable delivery capabilities distinguish professional suppliers from commodity vendors. Cost considerations must balance initial pricing against long-term performance and reliability. By evaluating these factors systematically, buyers can establish successful partnerships that deliver consistent results for their critical applications across aerospace, chemical processing, electronics, and medical device industries.

Ready to Source Premium Tantalum Alloy Plate? Partner with Chuanghui Daye

Shaanxi Chuanghui Daye brings over 30 years of rare metal expertise as your trusted tantalum alloy plate supplier. Our ISO 9001:2015 certified facility in China's Titanium Capital delivers consistent quality, competitive pricing, and rapid delivery for your critical projects. Experience professional technical support and reliable supply capabilities - contact us atinfo@chdymetal.com.

References

1. ASTM International. "Standard Specification for Tantalum and Tantalum Alloy Plate, Sheet, and Strip." ASTM B708-98 (Reapproved 2014).

2. Davis, Joseph R. "Refractory Metals and Alloys: Properties, Selection, and Applications." ASM International Materials Reference Book, 2nd Edition, 2019.

3. Miller, George L. "Tantalum and Niobium: Industrial Applications and Processing Technologies." Metallurgical Society of AIME Technical Publication Series, Volume 47, 2018.

4. International Organization for Standardization. "Quality Management Systems for Aerospace and Defense Industries." ISO 9001:2015 Implementation Guidelines, 3rd Edition.

5. Thompson, Robert K. "Corrosion Resistance of Refractory Metals in Chemical Processing Equipment." Journal of Materials Engineering and Performance, Volume 28, Issue 6, 2020.

6. Anderson, Patricia M. "Biocompatible Materials for Medical Device Manufacturing: Tantalum Applications and Processing." Medical Device Technology Handbook, 4th Edition, 2021.